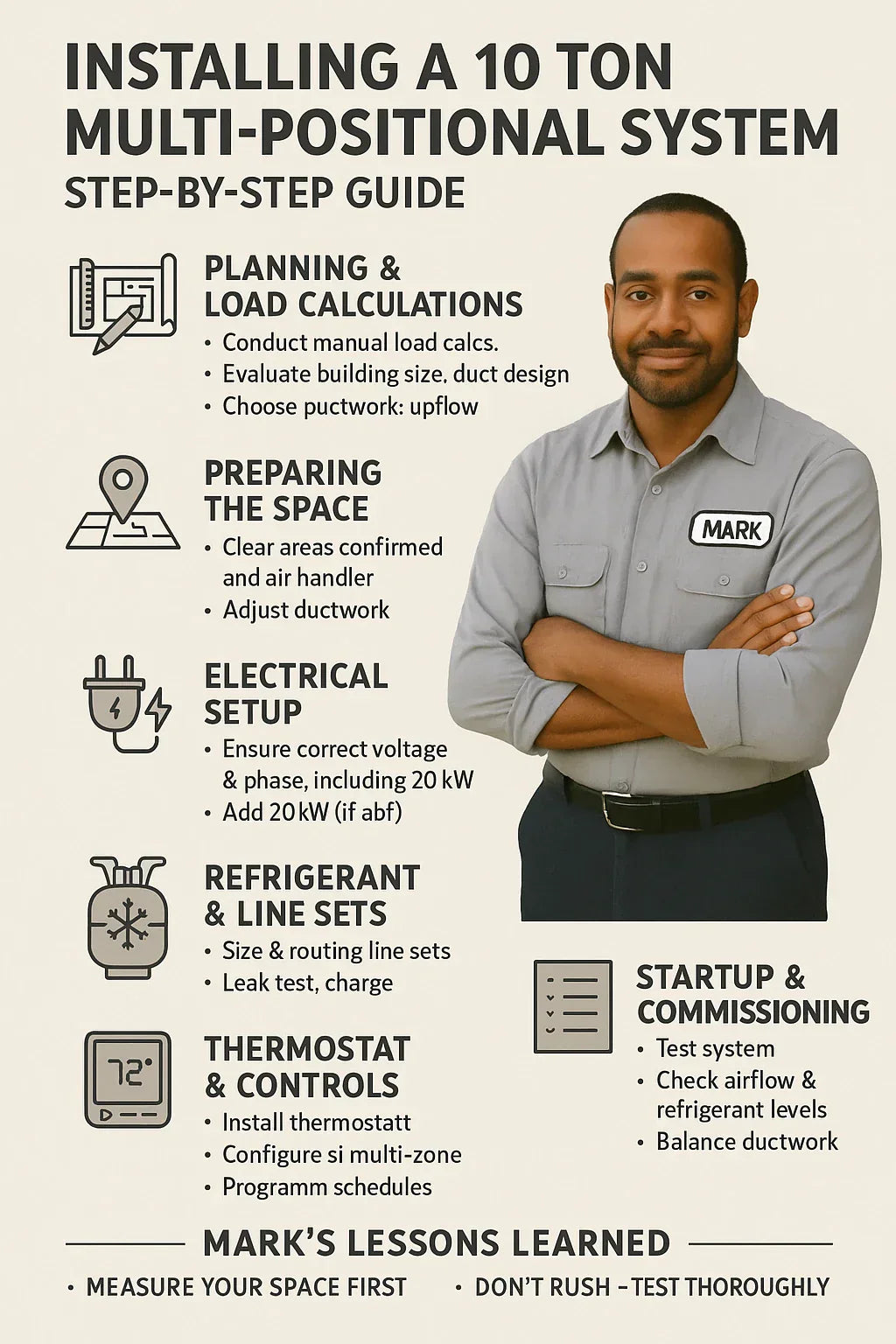

🏢 Introduction: The Big Step Up

When I first helped install a 10 ton commercial HVAC system, I quickly realized something: this isn’t like swapping out a 3-ton residential unit. It’s a whole new ballgame.

The Daikin 10 Ton Multi-Positional Split System with a 20kW Heat Kit is a powerhouse—ideal for offices, retail shops, restaurants, and community centers in the 3,000–4,000 sq. ft. range. But getting it set up right requires planning, precision, and respect for the scale of the equipment.

I learned a lot during my first project with one of these systems, and I want to share the step-by-step process along with the lessons learned the hard way. Whether you’re a facilities manager, small business owner, or contractor-in-training, this guide will help you understand what goes into setting up a 10 ton multi-positional system.

📐 Step 1: Planning & Load Calculations

Before a single wrench was turned, we had to answer the big question: Was 10 tons the right size?

That’s where a Manual N load calculation came in. Unlike residential systems (where Manual J is standard), commercial HVAC uses Manual N, which accounts for:

-

Square footage: Our project was a 3,400 sq. ft. office building.

-

Occupancy: 35 employees plus visitors.

-

Equipment heat loads: Computers, printers, and servers.

-

Lighting: Fluorescents and LED fixtures throughout.

-

Windows & insulation: Mixed—some older single-pane glass, some newer insulated windows.

The calculation confirmed what we suspected: 10 tons (120,000 BTUs of cooling) was the right fit.

Another decision was positioning. This Daikin system is multi-positional—meaning it can be installed:

-

Upflow (air handler pushes air upward into ductwork above).

-

Downflow (air handler pushes air downward into ductwork below).

-

Horizontal (air handler pushes air sideways for tight spaces).

We chose upflow, since the building had ductwork in the ceiling plenum.

📖 More about load calculations: ACCA Manual N.

🛠️ Step 2: Preparing the Space

Once we had the load and positioning figured out, it was time to prep the physical space.

Outdoor Condenser Placement

-

Needed at least 4 feet of clearance on each side for airflow.

-

Placed on a concrete pad with vibration isolation mounts.

-

Considered future service access—contractors need room to open panels.

Indoor Air Handler Location

-

Required a dedicated mechanical room with 36 inches of service clearance on the front.

-

We had to move some electrical conduit to make space.

-

Installed drip pans with drainage for condensation.

Ductwork Adjustments

This was the biggest hidden challenge. The old ductwork was designed for a 7.5 ton system, which meant:

-

Undersized trunks and returns.

-

Leaky flex duct branches.

We ended up upgrading to larger supply and return trunks to handle 4,000+ CFM airflow. Without this step, even the best 10 ton unit would have struggled.

📖 See ASHRAE HVAC standards for duct sizing guidelines.

🔌 Step 3: Electrical Setup

Large systems = serious electrical demands. Here’s what we had to account for:

-

3-phase power: Essential for many 10 ton systems (though some are available in single-phase).

-

Dedicated disconnect switch: Mounted near the outdoor unit.

-

Circuit breakers: Properly sized for both the condenser and air handler.

-

Wiring for the 20kW heat kit: This was the kicker. The heat kit added significant load—requiring a separate breaker and heavy-gauge wire.

We worked closely with a licensed electrician, since commercial codes are strict. Cutting corners here isn’t just illegal—it’s dangerous.

📖 Learn more from Energy.gov: Commercial HVAC Electrical Considerations.

🧊 Step 4: Refrigerant & Line Sets

For refrigerant lines, sizing matters. Too narrow, and the system starves. Too wide, and efficiency tanks.

-

Line set size: 7/8” suction line and 3/8” liquid line (check manufacturer’s specs).

-

Insulation: Wrapped in foam to prevent sweating.

-

Vacuum test: Pulled down to 500 microns to ensure no leaks.

-

Charge: Added R-410A per factory weight.

Future models may ship with R-32, which is more eco-friendly, but the installation principles stay the same.

📖 See HVAC.com’s refrigerant guide.

🌡️ Step 5: Thermostat & Controls

For a 10 ton system, the thermostat setup is more than just a box on the wall.

-

Commercial-grade thermostat: Chosen for compatibility with multi-stage cooling and heating.

-

Zoning options: We considered splitting the office into two zones but stayed with single-zone to keep costs down.

-

Programming: Built weekday schedules (cooler during occupied hours, higher setpoints at night).

This small step made a 10–15% impact on energy bills, just by aligning HVAC operation with building occupancy.

📖 ENERGY STAR has guides on smart thermostats.

🧾 Step 6: Startup & Commissioning

Here’s where the rubber meets the road. After weeks of planning and setup, it was time to flip the switch.

-

Airflow check: Confirmed CFM matched system specs.

-

Refrigerant pressures: Measured suction and discharge to verify charge.

-

Electrical draw: Checked amp readings to confirm no overload.

-

Duct balancing: Adjusted dampers to eliminate hot and cold spots.

The commissioning report was filed as part of the installation log—a critical document for warranty and future service calls.

📖 Learn more about commissioning from Modernize: HVAC Installation Costs & Commissioning.

✅ Mark’s Lessons Learned

Looking back, here are the key takeaways I’d share with anyone setting up a 10 ton system:

-

Measure first. Don’t assume your mechanical room can handle the air handler—these units are big.

-

Upgrade ducts. A 10 ton system can’t perform if choked by undersized ductwork.

-

Plan for downtime. Install + testing took three full days. Don’t promise tenants or employees same-day comfort.

-

Bring in licensed pros. Even if you’re handy, refrigeration and electrical work demand certification.

-

Document everything. Keep records of load calculations, electrical specs, and refrigerant charge.

🧹 Post-Install Checklist

Once everything was running smoothly, we made sure to wrap up with these steps:

-

✅ Registered the system warranty with Daikin.

-

✅ Logged installation data for future service.

-

✅ Scheduled seasonal maintenance reminders (spring + fall).

-

✅ Trained staff on filter changes and thermostat scheduling.

📖 See ACHR News: Commercial HVAC Maintenance.

📈 Conclusion: Confidence in the Setup

Installing a 10 ton multi-positional system isn’t just about bolting equipment together—it’s about careful planning, proper electrical and ductwork preparation, and meticulous commissioning.

From my perspective as a facilities manager, here’s the real takeaway:

-

Respect the size of the system.

-

Work with professionals.

-

Plan for the long haul.

If you do those things, your 10 ton Daikin system will deliver reliable, efficient comfort for 15–20 years.

In the next topic we will know more about: How Much Does a 10 Ton Commercial AC System Cost? Equipment, Labor & Long-Term Savings