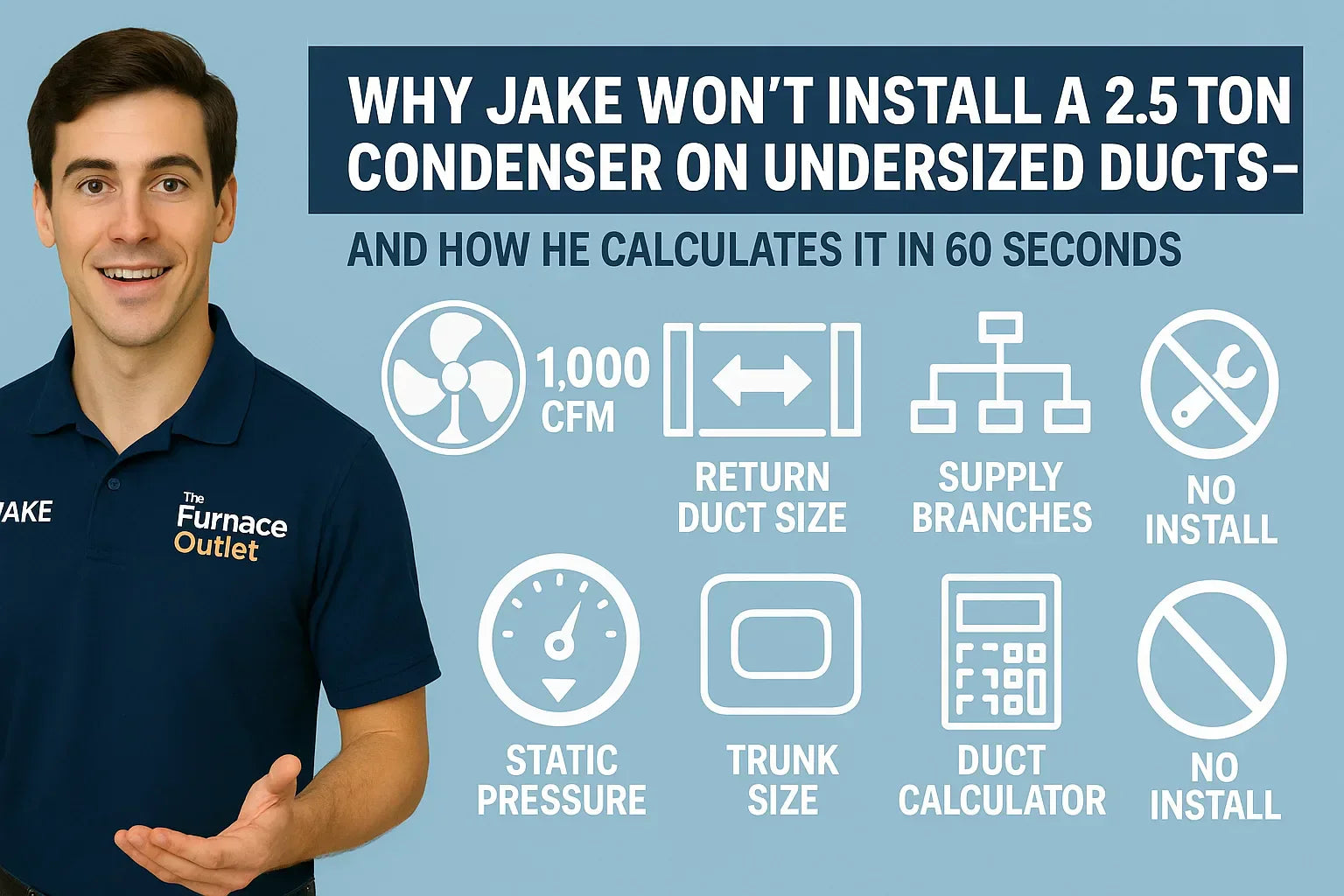

Most homeowners think a 2.5-ton condenser is a simple upgrade:

“Just hook it up — the house is already ducted.”

Jake knows better.

He refuses — absolutely refuses — to install a 2.5-ton R-32 condenser onto ductwork that cannot handle the airflow it requires.

Because undersized ducts don’t just reduce cooling.

They destroy compressors, ruin SEER2 performance, and create noisy, high-static systems that homeowners blame on the equipment rather than the real problem:

insufficient duct capacity.

Jake has one rule:

“If the ducts can’t move 1,000 CFM, I’m not installing a 2.5-ton system.”

And the best part?

Jake can determine duct adequacy in 60 seconds using a simple airflow formula he developed years ago.

This article breaks down why undersized ducts kill 2.5-ton condensers — and how Jake calculates duct sufficiency faster than most people can read a tape measure.

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model - GLXS3BN3010

🌀 1. Why a 2.5 Ton R-32 Condenser Needs 1,000 CFM (No Exceptions)

R-32 units — like the Goodman 2.5 Ton 13.4 SEER2 Model GLXS3B3010 — operate at:

-

higher refrigerant density

-

higher energy concentration

-

higher coil temperature differentials

This means:

Higher airflow is REQUIRED to prevent:

-

coil freeze-ups

-

high head pressure

-

compressor overheating

-

TXV hunting

-

short cycling

-

reduced SEER2

Jake explains it simply:

“2.5 tons = roughly 1,000 CFM of air.

If your ducts can’t deliver 1,000 CFM, you don’t have a 2.5-ton system.”

📏 2. Jake’s 60-Second Airflow Test (The “Return + Supply Rule”)

Jake evaluates a home’s duct system in under 60 seconds using two simple checks:

✔️ STEP 1: Measure Return Duct Size

A 2.5-ton system needs:

Return Requirement

-

16" round minimum, OR

-

20" x 20" rectangular, OR

-

Two 14" returns, OR

-

Equivalent area totaling ~300 square inches

Jake says:

“Undersized returns will choke a system faster than undersized supplies.”

✔️ STEP 2: Count Total Supply Duct Area

Jake checks supply branches:

Minimum requirements:

-

8 × 6” runs, OR

-

6 × 7” runs, OR

-

4 × 8” runs, OR

-

A trunk/branch combo supporting ~1,000 CFM

Each 6” branch = ~100 CFM

Each 7” branch = ~150 CFM

Each 8” branch = ~250 CFM

Jake mentally totals these in seconds.

If the supply cannot total 1,000 CFM, he refuses to install.

✔️ STEP 3: Check Main Trunk Sizes

A 2.5-ton system requires:

-

12" round minimum, OR

-

10x20 rectangular, OR

-

Equivalents totaling 1,000–1,200 CFM capacity

Jake says:

“If your trunk is smaller than 12 inches, your airflow is smaller than 2.5 tons.”

🔊 3. The Real Problem: Static Pressure (The Silent System Killer)

Most homeowners don’t know what static pressure is. Jake wishes more people did.

Static pressure is:

-

the resistance air faces moving through ducts

-

measured in inches of water column (in. wc)

A properly functioning system runs at:

0.3–0.5 in. wc total external static

Undersized ducts regularly hit:

0.8–1.2 in. wc

That’s 2–3× higher than the blower was designed for.

High static pressure causes:

-

loud airflow

-

coil starvation

-

overheating

-

ECM blower burnout

-

compressor failure

Jake explains it to customers like this:

“Your blower isn’t a miracle worker. If the ducts are too small, it’s like sucking air through a straw.”

🧊 4. What Happens When You Install a 2.5 Ton Condenser on Undersized Ducts

Jake guarantees failure in five areas:

❄️ 1. Coil Freezing

Not enough warm air across the coil → freezing → flooding → compressor damage.

🔥 2. High Head Pressure

Not enough airflow to cool the coil → head pressure spikes → R-32 systems shut down early.

🔊 3. Excessive Noise

High static = loud vents, loud blower, whooshing noises.

⚙️ 4. Efficiency Loss

Jake has measured 15–28% SEER2 loss on undersized duct systems.

💀 5. Early Compressor Death

Overheating + high head pressure = reduced compressor life span.

Jake refuses to put his name on an install like that.

🔍 5. Jake’s “3-Point Pre-Install Duct Check” (Used on Every House)

Jake does this before he even unloads the condenser:

1. Return Capacity Test

Must be at least 300 sq. in.

Otherwise, airflow is strangled from the start.

2. Supply Count Test

Must total 1,000 CFM or more.

3. Static Pressure Test (if needed)

Jake uses a manometer only when sizing seems questionable.

🛑 6. The One Case Jake Absolutely Refuses

Jake will NOT install a 2.5-ton condenser if:

-

the return is under 14"

-

the supply has fewer than 6 branches

-

the trunk is under 12" round

-

the total supply area is under 1,000 CFM

He tells homeowners:

“I’m not here to install a failure. I’m here to install a system.”

If the ductwork is undersized, Jake offers options:

-

add second return

-

upsize main trunk

-

add supply branches

-

convert supply to larger round

-

replace return filter rack

He’s never lost a customer by being honest.

📐 7. Jake’s 60-Second Airflow Formula (Write This Down)

Jake uses this formula:

CFM = Total Supply Area × Duct Efficiency Factor

For residential ducts:

-

Flex duct: 10–12 CFM per sq. in.

-

Metal duct: 12–20 CFM per sq. in.

Then he compares that number to:

2.5 tons = 1,000 CFM

If the system can’t reach it, he stops.

🔧 8. Jake’s Tools for Fast Duct Verification

1. Klein Tools Tape Measure

For quick dimension checks

https://www.kleintools.com/

2. Fieldpiece Manometer (SDMN5)

3. Ductulator (Trane or Carrier)

4. WrightSoft HVAC Sizing Tool

5. Goodman Engineering Manuals

6. ACCA Manual D (Duct Design Standard)

🔚 9. Final Word from Jake

Jake doesn’t care how good the 2.5-ton unit is.

If the ducts can’t move 1,000 CFM, he won’t install it.

Because he knows:

-

the compressor will run hot

-

the blower will run loud

-

the customer will lose efficiency

-

the system will short cycle

-

the install will fail prematurely

Jake always tells homeowners:

“Airflow is the real boss. Size the ducts right, and any system will shine.”

And with his 60-second airflow method, he never makes the wrong call.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Why Jake Double-Insulates the Suction Line (Even Though Most Pros Don’t)