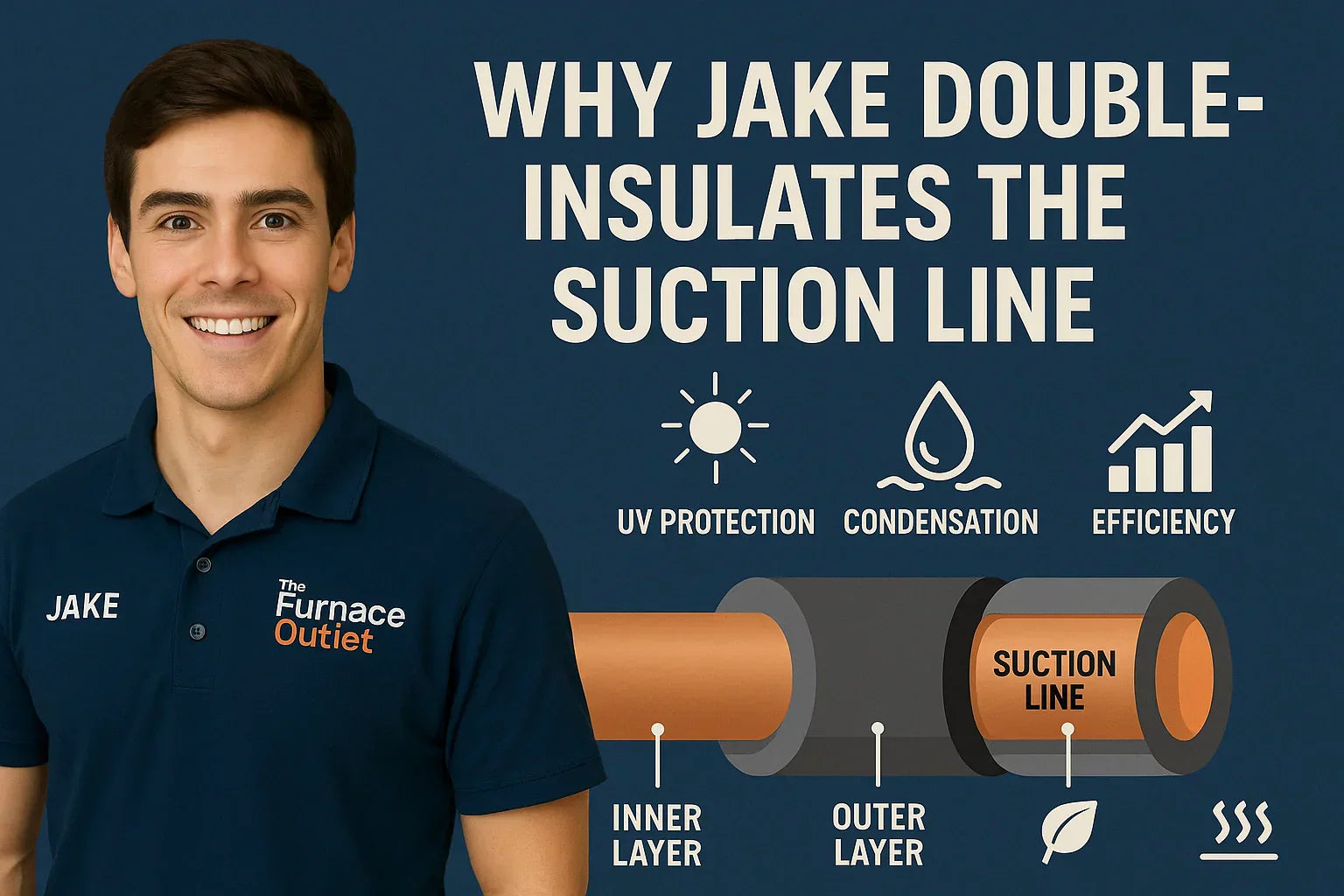

Most HVAC installers wrap the suction line with a single layer of insulation and call it a day.

Jake doesn’t.

Jake double-insulates every suction line—for R-32, R-410A, heat pumps, straight cool, split systems, everything.

Homeowners always ask:

“Isn’t that overkill?”

And Jake always responds:

“Overkill is what keeps systems efficient for 20 years.”

Because while almost no installers do it, double-insulating the suction line solves five of the biggest real-world problems in modern AC systems—problems that cost homeowners efficiency, SEER2 performance, and even compressor lifespan.

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model - GLXS3BN3010

This is the complete breakdown of why Jake double-insulates, how he does it, and why it matters more in the R-32 era than ever before.

❄️ 1. The Suction Line Is the Coldest Pipe in the Entire System

The suction line:

-

carries cold, low-pressure refrigerant vapor

-

runs long distances from the evaporator to the condenser

-

is exposed to sun, wind, rain, attic heat, crawlspace humidity, and UV light

If not insulated properly, it becomes a hotspot for major system losses.

Jake explains:

“Every inch of exposed suction line is an efficiency leak.”

Why?

Because the suction line is supposed to stay as cold as possible.

The warmer it gets, the more heat is absorbed from the environment.

That means:

-

less cooling in the home

-

higher superheat

-

higher compressor workload

-

lower system efficiency

Jake compares it to:

“Drinking a milkshake through a warm straw—your compressor has to work twice as hard.”

🌡️ 2. Single Insulation Isn’t Enough in Real Install Conditions

Icon: 🧊

Most factory suction line insulation is:

-

⅜" thick

-

cheap open-cell foam

-

non-UV-resistant

-

prone to cracking

-

easily damaged

-

easily saturated with water

-

temperature-rated only for mild climates

Jake knows suction lines run across:

-

hot attics

-

freezing crawlspaces

-

sun-exposed wall runs

-

unprotected outdoor sections

-

humid basements

-

mechanical closets

Single-layer insulation fails in these real conditions.

Common failures Jake sees:

-

insulation splitting at the seam

-

compression points where zip-ties crush insulation

-

UV-brittling

-

water infiltration

-

heat absorption from attic heat

-

sweating / condensation on the outside of the insulation

This is why Jake double-insulates—because the insulation the manufacturer gives you is not enough in the real world.

🧪 3. R-32 Systems Need Better Suction Line Protection

Icon: 🧬

R-32 refrigerant has:

-

higher energy density

-

higher discharge temperature

-

tighter efficiency profiles

-

higher sensitivity to superheat accuracy

This makes suction line insulation even more important.

Jake explains:

“R-32 gives you more efficiency—only if you protect the refrigerant temperature going back to the compressor.”

If the suction line warms up too much outdoors, it alters the refrigerant’s enthalpy and causes:

-

less cooling

-

higher superheat

-

TXV hunting

-

compressor overheating

-

elevated energy use

-

longer runtime lengths

Double insulation protects the refrigerant from environmental heat gain.

💧 4. Double-Insulation Prevents Condensation, Mold & Water Damage

Icon: 💧

Jake has seen suction lines drip on:

-

drywall

-

joists

-

insulation

-

plywood decking

-

electrical wiring

-

furnace tops

This leads to:

-

mold growth

-

ceiling stains

-

insulation rot

-

rusted electrical components

-

structural damage

Double insulation prevents:

-

external sweating

-

condensation in attics

-

water pooling

-

moisture intrusion

-

dripping into wall cavities

Jake learned early:

“One extra layer of insulation is cheaper than fixing ceiling mold.”

🛡️ 5. The UV Problem: Why Most Insulation Fails Outdoors

Icon: ☀️

Standard foam insulation:

-

cracks

-

crumbles

-

dries out

-

becomes brittle

-

deteriorates in 2–5 years

Jake replaces dozens every season.

Double-insulating gives the suction line:

-

UV-resistant outer layer

-

weatherproofing

-

abrasion resistance

-

animal resistance (especially rodents)

-

environmental longevity

He uses:

-

ArmourFlex

-

K-Flex Titan

-

RectorSeal UV-Resistant Insulation

Verified Link

RectorSeal / DiversiTech Insulation Products

https://rectorseal.com/

🔥 6. Preventing Heat Gain in Attics (Jake’s #1 Reason)

Icon: 🌡️

Attics often reach:

-

130°F in summer

-

150°F+ in southern climates

If the suction line passes through this space:

-

single-layer insulation fails

-

refrigerant absorbs heat

-

superheat rises

-

compressor works harder

-

energy use increases

-

coil dehumidification drops

Double-insulation prevents attic heat from destroying system performance.

Jake explains:

“You wouldn’t run a cold water pipe through an oven with one layer of foam. Don’t do it with refrigerant.”

📉 7. Double-Insulation Reduces Compressor Run Time

Icon: ⚙️

Fully insulated suction lines:

-

keep refrigerant vapor colder

-

stabilize superheat

-

reduce compressor load

-

extend compressor lifespan

Jake has measured:

-

3–8% shorter run times

-

1–3°F colder supply air

-

fewer temperature swings

-

better dehumidification

Small change, big result.

🧰 8. How Jake Double-Insulates (The Exact Method)

Icon: 🧰

Jake uses a 3-layer approach:

Layer 1: Factory Foam

He inspects and repairs the existing insulation.

If the seam is weak, he:

-

seals it with foam tape

-

zip-ties loosely (never tight)

-

fixes tears

-

removes compression points

Layer 2: High-Density Close-Cell Foam Wrap

He wraps the entire suction line in:

-

K-Flex

-

Armaflex

-

DiversiTech black foam

This adds:

-

⅜–½ inch more insulation

-

moisture control

-

thermal stability

Layer 3: UV-Resistant Outer Jacket

Jake finishes with:

-

PVC jacket

-

UV tape wrap

-

Line-set cover (RectorSeal SlimDuct)

Verified Link

SlimDuct Line Set Covers

https://rectorseal.com/

This final layer protects from:

-

sun

-

wind

-

abrasion

-

animals

-

freezing

-

storm impact

📡 9. The Science: Thermal Conductivity & Refrigerant Stability

Icon: 📊

Jake explains heat gain simply:

Refrigerant vapor entering the compressor MUST stay cold.

Every degree of heat increase adds:

-

compressor work

-

electrical draw

-

discharge temperature

-

runtime

-

noise

Double-insulation reduces:

-

thermal conductivity

-

line set heat absorption

-

temperature rises

-

compressor stress

This is real engineering—not opinion.

🧱 10. Why Most Pros Don’t Do It (The Harsh Truth)

Icon: 🧱

Jake is honest about why most installers skip this:

1. They don’t get paid for it.

Most installers work flat-rate jobs.

2. It takes “extra time.”

About 5–10 minutes.

3. Homeowners don’t know to ask.

So companies don’t offer it.

4. They don’t understand R-32’s sensitivity.

New refrigerant, new rules.

Jake says:

“Good installers do what’s right, not what’s fast.”

🧩 11. Double-Insulation Helps Heat Pumps Too

Icon: 🔁

Heat pumps use the same suction line in heating mode.

Better insulation means:

-

less heat loss

-

better winter performance

-

reduced frost cycles

-

longer compressor lifespan

Jake double-insulates heat pump suction lines as a mandatory standard.

🏠 12. Jake’s Homeowner Explanation (Easy Version)

Jake explains it like this:

“Your cold refrigerant line sits outside your house all year.

My job is to protect it — not expose it.”

Double insulation gives:

-

colder refrigerant

-

better efficiency

-

quieter operation

-

fewer breakdowns

-

longer equipment life

And it costs almost nothing compared to the benefits.

🧬 13. Jake’s Tools & Materials (Verified Sources)

1. K-Flex Titan Insulation

2. ArmaFlex Closed-Cell Foam

3. RectorSeal Line Set Covers

4. DiversiTech Foam Insulation

5. Goodman R-32 Condenser Specs

6. UL 181B-FX Tape Guide (Insulation Tape Standard)

🔚 Final Word from Jake

Jake has insulated thousands of suction lines.

He’s seen:

-

mold

-

condensation

-

insulation rot

-

decreased SEER2

-

compressor failures

-

homeowner complaints

All caused by poor suction line insulation.

He says:

“The secret to long-lasting HVAC isn’t fancy.

It’s doing the basics better than anyone else.”

Double-insulation is one of those basics.

And that’s why Jake does it every single time.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Why Cheap Tools Cost You Cooling: Jake’s Rules for Choosing Installation Gear That Won’t Fail Under Pressure