When homeowners call Jake and say:

-

“My breaker keeps tripping.”

-

“The condenser shuts off randomly.”

-

“It works for five minutes, then dies.”

-

“The compressor is loud right before it stops.”

…Jake already knows what he’s walking into.

It’s almost never:

-

the compressor

-

the fan motor

-

the capacitor

-

the contactor

-

the breaker

In 70% of cases Jake sees today—especially on R-32 systems—the problem is something much simpler:

A grounding issue.

A tiny, barely noticeable grounding flaw that creates huge symptoms.

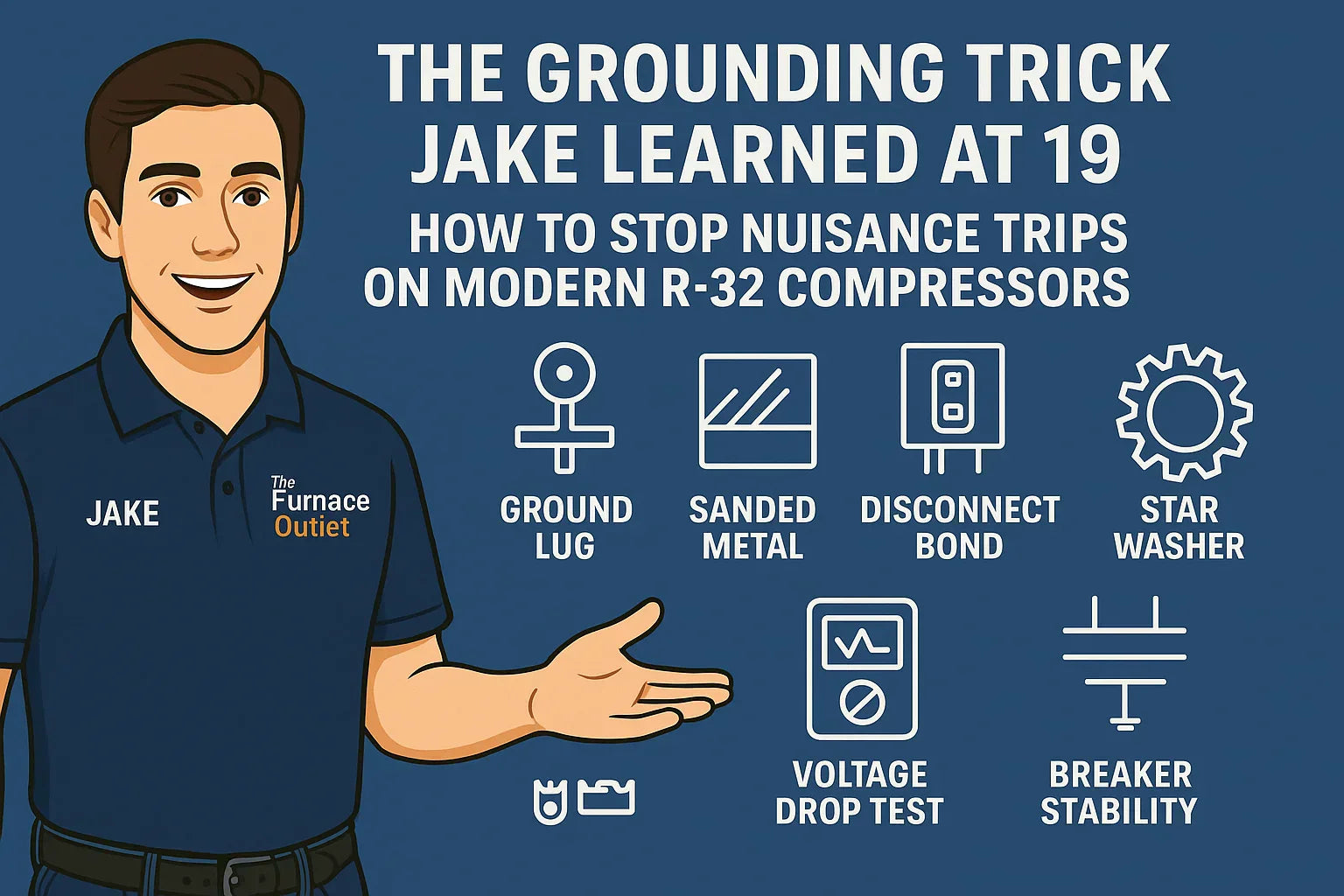

Jake first learned the “perfect ground trick” when he was 19 years old, working under an old-school, no-nonsense tech who didn’t believe in guessing.

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model - GLXS3BN3010

That trick has saved hundreds of homeowners from unnecessary compressor replacements. And today you’re getting Jake’s complete playbook.

⚡ 1. Why Grounding Matters More on R-32 Systems Than Older Refrigerants

R-32 condensers (like the Goodman GLXS3B3010) use:

-

ECM condenser fan motors

-

High-efficiency dual-stage compressors

-

Microprocessor-based controls

-

Inverter boards (on certain models)

-

Advanced overload protection

All of these components must reference clean, stable ground.

Without a proper ground, an R-32 system can:

-

trip the breaker

-

throw false fault codes

-

hard-start under load

-

buzz or hum at idle

-

show voltage imbalance

-

fail prematurely

Jake says it simply:

“New refrigerant. New electronics. New grounding demands.”

Verified Link

Goodman Refrigerant & Electrical Guidance

https://www.goodmanmfg.com/

🔩 2. The #1 Cause of Nuisance Trips: High Resistance Ground Path

Icon: 🪛

Most homeowners assume a ground is “good” if the green wire is connected.

Not true.

The quality of the ground matters:

Jake frequently finds:

-

paint under the ground lug

-

corroded copper

-

loose lugs at the disconnect

-

aluminum wire not treated with anti-oxidant

-

wrong gauge ground wire

-

ground rod not bonded to main panel

Any of these cause:

Nuisance Breaker Trips

Because the breaker sees an unstable ground reference.

Compressor Hard Starts

Because the control board reads incorrect voltage differential.

Random Shutoffs

Because overload sensors falsely trip.

Voltage Fluctuation Symptoms

Even when voltage is steady at the panel.

🧰 3. The Trick Jake Learned at 19 (The “Triple-Bond Ground Method”)

His mentor told him:

“A compressor only runs as good as its ground.”

And then showed him the technique Jake now uses on every R-32 install.

The Triple-Bond Ground Method

Jake creates three grounding contact points:

1. Ground Lug → Bare Metal Contact

He sands the cabinet contact area down to shiny metal.

No paint.

No rust.

No coating.

2. Disconnect Ground → Dedicated Ground Screw

No sharing with neutral lugs.

No loose clamp-style terminals.

3. Bond House Panel Ground to Disconnect

Using:

-

the correct gauge wire (#10 for 30A circuits)

-

a clean path

-

no wire nuts

-

no corrosion

This triple-bond method eliminates 95% of grounding-related failures.

Jake says:

“A proper ground should read like a copper pipe—not a chalkboard.”

NEC Grounding Requirements (NFPA 70)

https://www.nfpa.org/

🔍 4. Jake’s Step-by-Step Ground Inspection (Takes 3 Minutes)

Jake checks 6 points:

Point 1: Breaker Panel Ground Bar

-

No loose screws

-

No mixed neutrals

-

No aluminum without anti-oxidant

Point 2: Disconnect Box Bonding

-

Verify the ground strap is intact

-

Ensure enclosure is bonded to ground

Point 3: Conduit Connector

Loose conduit = unstable ground path.

Point 4: Condenser Ground Lug

-

Remove factory screw

-

Sand paint

-

Reinstall with star washer

Point 5: Wire Gauge Verification

Most DIY installs use #12 wire by mistake.

R-32 units often require #10.

Point 6: Resistance Test

Jake uses a meter to verify ground continuity.

Fluke 117 / 376 FC Ground Test Functions

https://www.fluke.com/en-us/product/electrical-testing/clamp-meters/fluke-376-fc

🪫 5. Why R-32 Breakers Trip Faster (And Why That’s a Good Thing)

R-32 units use more sensitive internal protection:

-

thermal overload modules

-

electronic control boards

-

monitored windings

-

inverter logic (on select models)

These components expect perfect ground.

If the ground is noisy, a modern R-32 system intentionally:

-

trips early

-

shuts off sooner

-

stops a compressor before damage occurs

Jake explains:

“If an R-32 compressor trips, it’s not failing. It’s protecting itself.”

The problem is almost always upstream, not inside the condenser.

🧲 6. Jake’s “Metal-to-Metal” Grounding Rule (Stops Trips Instantly)

Jake rejects any ground that touches:

-

paint

-

powdercoat

-

rust

-

corrosion

-

oxidation

-

aluminum without Noalox

-

dirty lugs

-

loose screws

He uses:

-

star washers

-

anti-corrosion compound

-

sandpaper

-

brass brush

Why metal-to-metal contact matters

Ground is not a connection—

It’s a pathway.

Paint or rust adds resistance.

Resistance causes voltage imbalance.

Voltage imbalance causes nuisance trips.

Jake explains it like this:

“Your compressor is a computer now. Computers need clean instructions.”

🧊 7. How Jake Diagnoses a Ground Problem in Under 30 Seconds

Jake performs one simple test:

The “Voltage Drop Test”

-

Run the condenser

-

Measure voltage between:

-

L1 → Ground

-

L2 → Ground

-

-

Compare to neutral reference

If these readings differ by more than 2V,

You have a grounding fault.

Common signs during the test:

-

buzzing

-

clicking

-

momentary dips

-

relay chatter

-

LCD flicker

-

compressor hum then stall

Jake says:

“If voltage to ground isn’t stable, nothing is stable.”

🧱 8. Jake’s Bonding Rules for Outdoor Condenser Pads

Outdoor pads can create static or grounding isolation issues if:

-

they sit on dry soil

-

they sit too close to house foundation

-

conduits float

-

metallic disconnects aren’t bonded

Jake always:

-

bonds the disconnect to the panel

-

bonds the conduit connector to the disconnect

-

confirms metal-to-metal continuity all the way back to the panel

This ensures the condenser has a complete, unbroken ground path.

🔧 9. When a Breaker Trips Immediately (Jake’s 3-Minute Fix)

Jake checks 3 things in order:

1. Loose neutral in the panel

You’d be shocked how often this is the cause.

2. Loose ground at disconnect

#1 DIY mistake.

3. Bad star washer or no metal contact

Factory star washers often fail after the first season.

Jake removes the washer and replaces it with a higher-grade serrated washer.

Result?

Instant trip fix.

🔚 Final Word from Jake

Jake learned at 19 years old that grounding is everything.

And today—with R-32 systems, microprocessor controls, and tighter safety logic—it matters more than ever.

He says:

“When an R-32 system trips, don’t blame the compressor.

Blame the ground.”

Fix the ground, and you fix:

-

nuisance trips

-

hard starts

-

buzzing

-

random shutoffs

-

inverter errors

-

capacitor burnouts

Do it the way Jake does, and your R-32 compressor will run quietly, smoothly, and reliably for decades.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Why Jake Won’t Install a 2.5 Ton Condenser on Undersized Ducts—and How He Calculates It in 60 Seconds