This one makes people uncomfortable.

I’ve had apprentices look at me sideways.

I’ve had homeowners ask if something’s wrong.

I’ve even had inspectors pause when they see what I’m doing.

But here’s the truth:

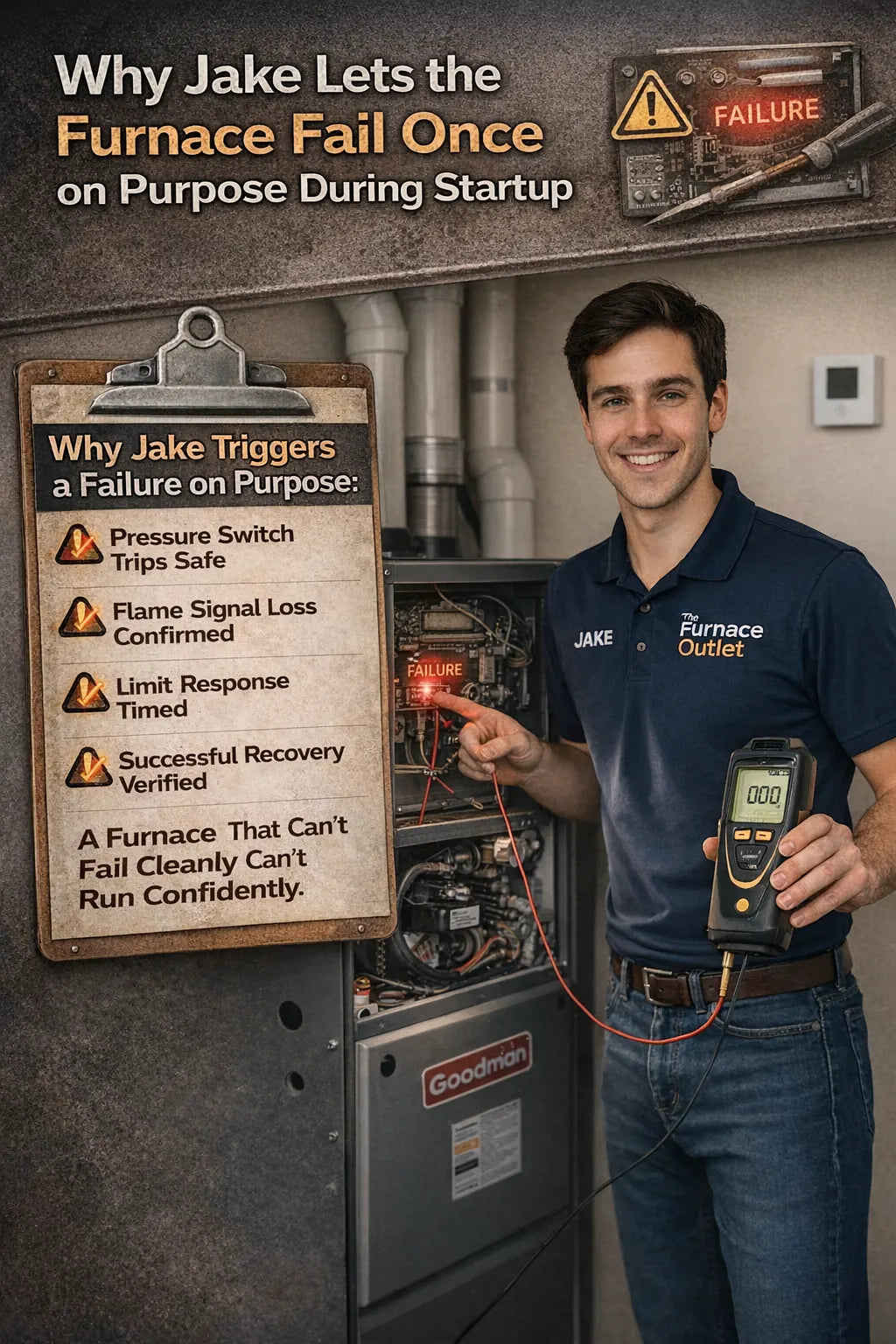

If a furnace can’t fail safely during startup, it’s not ready to run.

So yes — I let it fail once.

On purpose.

Under control.

Because I’d rather watch a system fail while I’m standing in front of it than hear about it when I’m not.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

🧠 Failure Isn’t the Enemy — Surprise Is

Most startup problems don’t come from dramatic breakdowns.

They come from unknown reactions.

Pressure switches that barely close.

Limits that trip late.

Control boards that hesitate before locking out.

Those issues don’t always show up during a “perfect” startup.

They show up when something goes wrong.

So I introduce something wrong — safely — and see how the furnace reacts.

🔁 What “Failing Once” Actually Means (And What It Doesn’t)

Let’s be clear.

I’m not damaging equipment.

I’m not bypassing safeties permanently.

And I’m not doing anything reckless.

A controlled failure means:

-

Temporarily interrupting a condition

-

Observing the response

-

Verifying recovery

-

Restoring normal operation

Think of it like testing airbags — you don’t wait for a crash.

🧯 Why High-Efficiency Furnaces Demand This Test

On furnaces like the Goodman GR9S960803BN, everything is tighter:

-

Pressure switches are more sensitive

-

Inducers respond faster

-

Control boards make quicker decisions

That’s good — but only if everything reacts correctly.

If something is marginal, a clean startup won’t expose it.

A controlled failure will.

🌬️ Test #1: Pressure Switch Interruption

One of the first things I test is the pressure switch.

I want to know:

-

How fast it opens

-

How fast the board reacts

-

Whether the system retries properly

-

If it locks out when it should

What I’m watching for:

-

Immediate shutdown

-

Clean retry sequence

-

No hesitation

-

No erratic behavior

A slow or confused response here tells me the system will struggle in windy conditions or long vent runs later.

ASHRAE outlines how pressure-sensitive controls must respond reliably under changing conditions, not just ideal ones:

https://www.ashrae.org/technical-resources

🔥 Test #2: Flame Proving Loss

Next, I want to see how the furnace reacts when flame signal disappears.

This test answers big questions:

-

Does the gas valve close immediately?

-

Does the board recognize flame loss cleanly?

-

Does ignition retry properly?

-

Does timing feel confident or sloppy?

A furnace that hesitates during flame loss isn’t safe — even if it “works.”

And this is where marginal grounding or weak flame sensing shows up fast.

The flame rectification principle is well documented by Honeywell’s combustion control resources:

https://customer.honeywell.com

🌡️ Test #3: Limit Response Timing

Limits aren’t there to save comfort — they’re there to save equipment.

During startup, I want to know:

-

How fast the limit reacts

-

Whether the blower responds correctly

-

If the furnace resets cleanly

-

How it behaves after recovery

I don’t need a full overheat scenario.

I just need to know the limit isn’t lazy.

A lazy limit doesn’t trip when it should — and that’s how heat exchangers die early.

The U.S. Department of Energy has repeatedly linked improper limit operation to reduced furnace lifespan:

https://www.energy.gov

🔄 What Recovery Tells Me About the Control Board

Failure is only half the story.

Recovery is the real test.

When the furnace restarts, I watch:

-

Ignition confidence

-

Timing consistency

-

Blower behavior

-

Flame stability after reset

A good control board doesn’t act embarrassed after a failure.

It resets clean.

It starts confidently.

It behaves like nothing happened.

Anything else tells me something’s marginal.

⏱️ Why I Do This Early — Not After an Hour

Some installers wait until the furnace has been running a while.

I don’t.

I test failure early because:

-

Components are cold

-

Tolerances are tight

-

Weaknesses show faster

-

Recovery behavior is more honest

If it can recover cold, it’ll recover warm.

If it struggles cold, it’ll fail later.

📉 The “It Ran Fine Yesterday” Problem

Most callbacks sound like this:

“It was working fine… until it wasn’t.”

That’s because the system was never tested under stress.

A marginal pressure switch works — until wind changes.

A borderline flame sensor works — until humidity shifts.

A lazy limit works — until dust builds up.

Controlled failure during startup eliminates surprises.

🧰 Tools Help — But Only If You Know What You’re Watching

Yes, I use tools.

But tools don’t tell you confidence.

Behavior does.

You can have perfect readings and still have a system that panics under stress.

🧾 What I Write Down After a Controlled Failure

My notes don’t say:

“Tested safeties — OK”

They say:

-

“Immediate shutdown on PS open”

-

“Clean retry after flame loss”

-

“Limit reset normal”

-

“No hesitation on recovery”

Those notes matter months later.

Because when something does fail, I know whether it’s new — or something that was always borderline.

🧠 Jake’s Rule: If It Can’t Fail Cleanly, It Can’t Run Reliably

Failure isn’t a mistake.

Unplanned failure is.

When I let a furnace fail once on purpose, I’m not being rough with it.

I’m teaching it how to behave when the real world pushes back.

And the furnaces that pass this test?

They’re the ones I never hear about again.

🔚 Final Thought: Startup Isn’t About Making It Run

Anyone can make a furnace run.

Startup is about making sure it knows how to:

-

Stop safely

-

Think clearly

-

Recover confidently

If a system can’t do that in front of me,

I don’t trust it behind a wall.

So yes — I let it fail once.

Because after that,

it usually doesn’t fail again.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: The GR9S Blower Isn’t Loud — Your Startup Is: Jake’s Airflow Truth Test