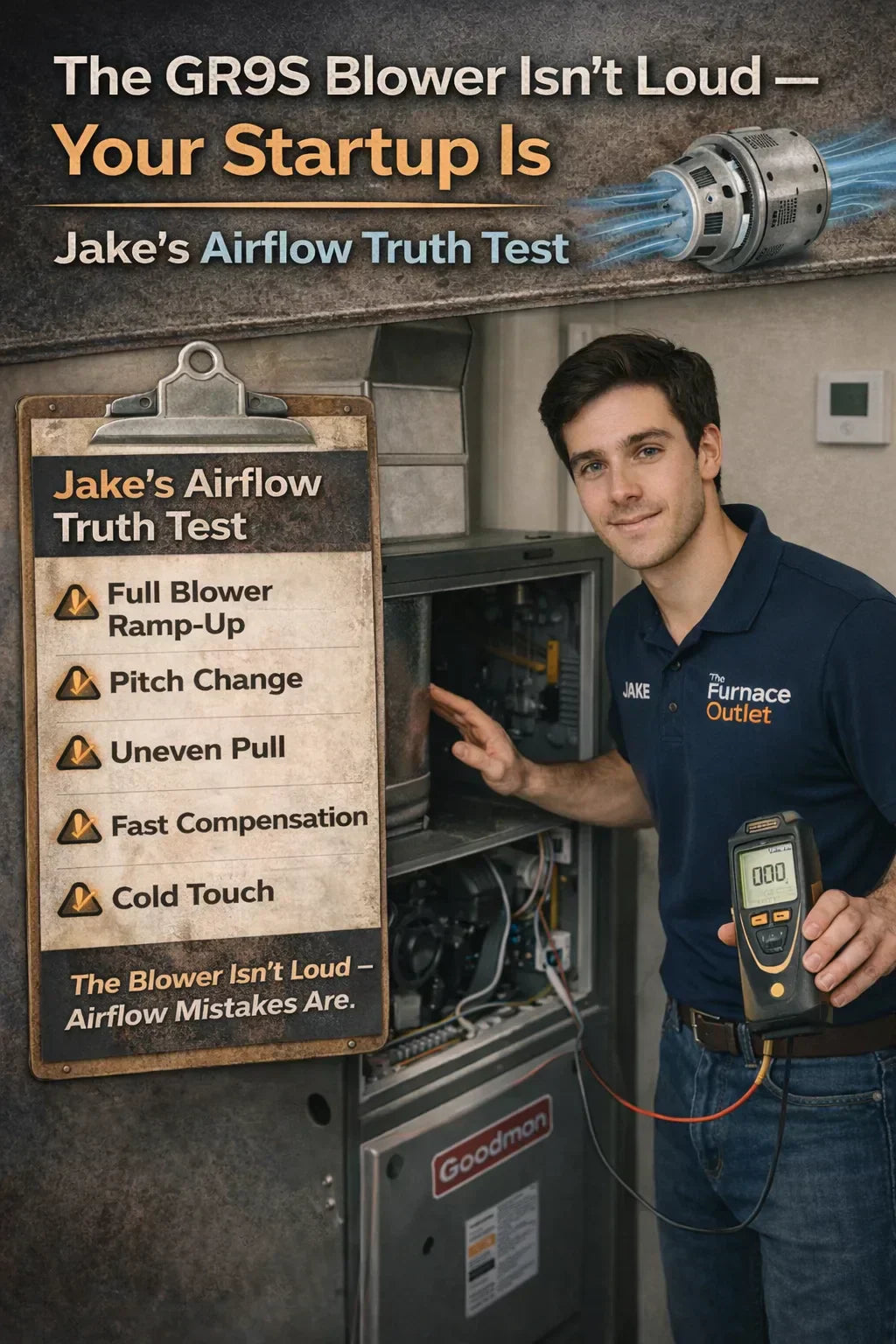

Jake’s Airflow Truth Test

If a homeowner tells me,

“That furnace is loud,”

my first thought isn’t bad blower.

It’s bad startup.

I’ve installed and started up enough Goodman GR9S furnaces to say this without hesitation: the blower isn’t loud — airflow mistakes are.

Noise is rarely a defect. It’s almost always feedback.

And startup is where the system tells you the truth — if you know how to listen.

🧠 Why Blower Noise Is a Startup Problem, Not a Hardware Problem

The GR9S uses a 9-speed ECM-style blower.

That motor is designed to adapt, compensate, and push through resistance.

That’s a blessing — and a curse.

Because when airflow is wrong, the blower doesn’t quit. It fights.

And when it fights, it makes noise.

Startup is where you decide whether that blower works with the system — or against it for the next 15 years.

👂 First Rule: Identify the Noise Before Measuring Anything

Before I grab a manometer or airflow hood, I stop and listen.

Different noises tell different stories:

-

Whistle → Restriction

-

Low rumble → Turbulence or overspeed

-

Thump on ramp-up → Duct or cabinet tension

-

Flutter → Filter or return issue

Meters confirm. Ears diagnose.

If you don’t identify the sound first, you’ll chase numbers and miss the cause.

📐 The Return Side: Where Most Startup Noise Is Born

If the return is wrong, nothing downstream matters.

During startup, I inspect:

-

Return opening size vs blower capacity

-

Sharp transitions

-

Filter fit and bowing

-

Panned returns choking airflow

A common mistake?

“The return was already there.”

That doesn’t mean it’s right.

A blower pulling against a restricted return will:

-

Ramp aggressively

-

Create suction noise

-

Transmit vibration into the cabinet

And homeowners hear that as “the furnace is loud.”

🧪 Jake’s Airflow Truth Test (No Tools Required)

Here’s my silent test during startup:

-

Let the blower ramp to full heat airflow

-

Stand at the return

-

Listen for pitch changes

-

Feel for uneven pull

-

Watch how fast the blower ramps

If the blower ramps hard and fast, it’s compensating.

That tells me airflow is wrong — even if static pressure later looks “acceptable.”

🔄 Why the 9-Speed Blower Exposes Bad Installs

Older PSC motors hid airflow problems.

ECM-style blowers expose them.

On the GR9S, the blower:

-

Increases torque when resistance rises

-

Adjusts speed to hit target airflow

-

Pushes until it can’t

That means:

-

Undersized ducts get louder over time

-

Filters that “almost fit” start to scream

-

Return restrictions turn into whistling complaints

The motor is doing its job. The startup didn’t.

📉 Static Pressure Isn’t the Whole Story

Yes — I measure static.

But I never start there.

Because static pressure doesn’t tell you:

-

Where turbulence is occurring

-

Whether airflow is smooth or chaotic

-

How transitions behave dynamically

A system can be within static limits and still sound terrible.

ASHRAE explains that airflow quality depends on duct design and transitions, not just pressure values:

https://www.ashrae.org/technical-resources

🧯 Cabinet Noise: The Hidden Airflow Multiplier

Airflow noise doesn’t just come from ducts.

It comes from cabinet stress.

During startup, I check:

-

Door fit

-

Screw tension

-

Panel alignment

-

Gasket compression

If the cabinet is under stress, airflow vibration turns into sound.

And that sound gets blamed on the blower.

It’s not the blower.

🌬️ Supply Side Checks Most Installers Skip

On startup, I look past the plenum.

I want to know:

-

Are takeoffs too close?

-

Are dampers partially closed?

-

Are flex runs kinked?

-

Are boots undersized?

High-velocity air hitting poor transitions creates:

-

Whooshing

-

Roaring

-

Low-frequency rumble

AMCA’s airflow guidance confirms that velocity and transition design heavily influence noise levels:

https://www.amca.org

🔊 Heat vs Cool Airflow: Why Noise Changes by Mode

A system that’s quiet in cooling can be loud in heating.

Why?

Because:

-

Heating airflow is often lower

-

Ducts behave differently under warm air

-

Blower torque changes

-

Static pressure profile shifts

That’s why I always evaluate noise during heat startup, not just cooling.

Startup in heat mode tells the real story.

🛠️ Tools Confirm — They Don’t Diagnose

Yes, I use tools.

But tools don’t tell you why the blower is loud.

Airflow behavior does.

🧾 What I Document When Airflow Is Right

My startup notes don’t say:

“Blower OK”

They say:

-

“Smooth ramp”

-

“No whistle at return”

-

“Stable airflow sound”

-

“No cabinet resonance”

Because months later, when someone says:

“It’s getting louder,”

I know whether airflow changed — or something else did.

🏠 Why Homeowners Always Blame the Furnace

Homeowners don’t hear airflow.

They hear noise.

So they blame:

-

The furnace

-

The brand

-

The motor

They don’t blame:

-

The return

-

The filter

-

The duct layout

That’s our job.

And startup is where we decide whether that blame ever happens.

🧠 Jake’s Rule on Blower Noise

If the blower is loud,

it’s telling you something.

If you silence it with adjustments,

you fix symptoms.

If you listen to it during startup,

you fix causes.

The GR9S blower isn’t loud.

But it will absolutely tell on a bad startup.

🔚 Final Thought: Quiet Is a Setup, Not a Feature

Quiet operation doesn’t come from marketing brochures.

It comes from:

-

Correct airflow

-

Honest startup

-

Listening before measuring

-

Fixing resistance, not fighting it

If your startup is clean,

the blower stays quiet.

If your startup is rushed,

the blower becomes the messenger.

And trust me —

you don’t want that message delivered at midnight.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Startup Heat Rise Lies: Why Jake Never Trusts the First Reading