If you think gas pressure is just a number on a manometer, you’re already behind.

Yes — inches of water column matter.

Yes — specs exist for a reason.

But after years of startups, callbacks, and late-night no-heat calls, I can tell you this with confidence:

Gas pressure doesn’t just measure — it behaves.

And the flame tells you everything long before a gauge does.

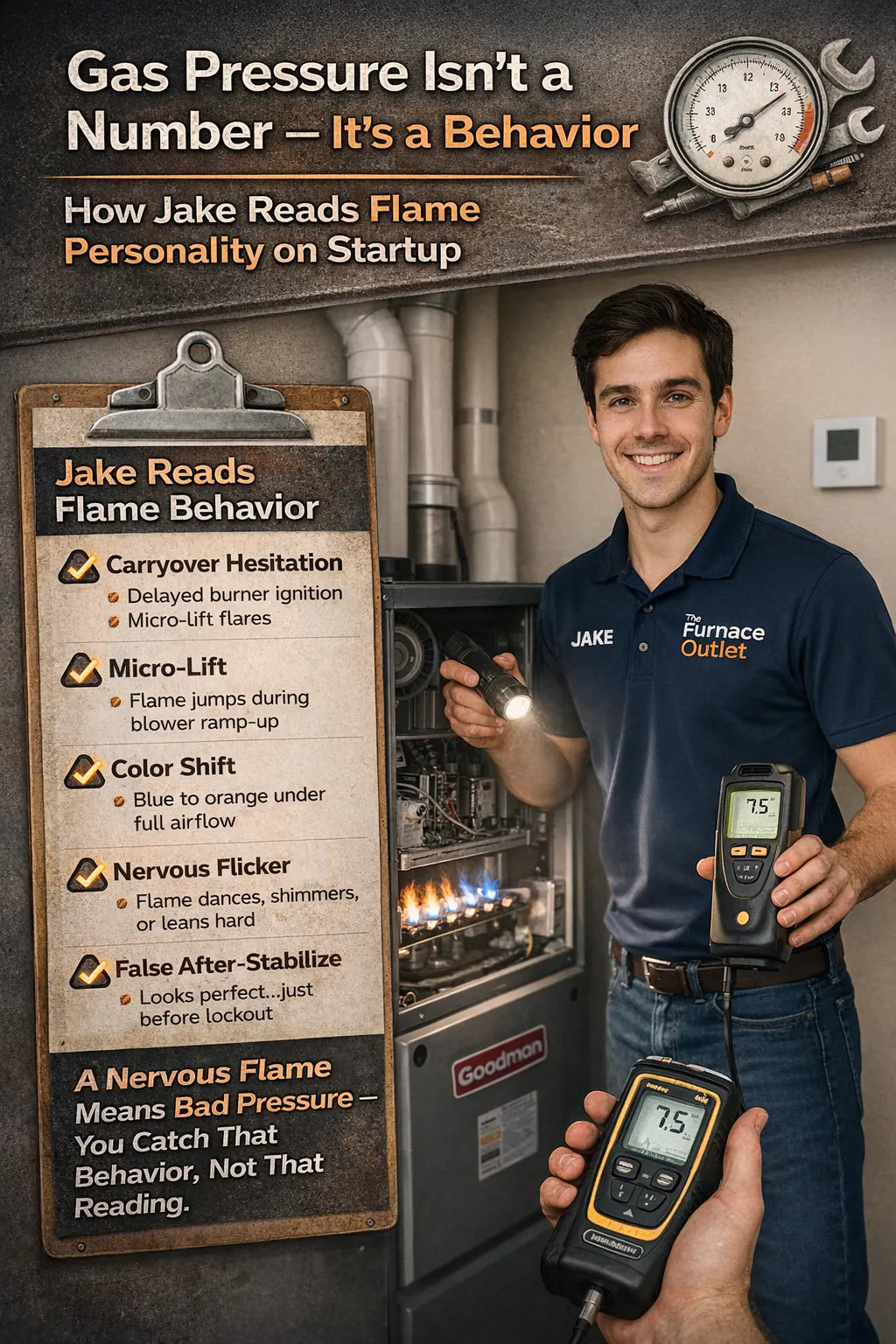

This article is about how I read flame personality during startup — especially on high-efficiency furnaces like the Goodman GR9S960803BN — and why installers who only trust numbers miss the early warning signs that lead to real-world failures.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

🧠 Why the Flame Tells the Truth Before the Gauge

A manometer shows you a snapshot.

A flame shows you a story.

On startup, the flame reacts to:

-

Gas pressure stability

-

Airflow balance

-

Manifold design

-

Venting behavior

-

Cabinet pressure changes

That’s why I watch the flame before I trust any reading.

Because the flame doesn’t lie — it just reacts.

👀 The First Ignition Moment (Where Everything Shows Up)

The first ignition cycle is sacred.

I’m watching:

-

How fast the flame establishes

-

Whether it hesitates or snaps

-

If carryover is clean or lazy

-

Whether the flame anchors immediately or wanders

A healthy startup flame:

-

Lights smoothly

-

Establishes evenly across burners

-

Holds its shape without dancing

An unhealthy one tells you there’s a conversation happening between gas, air, and pressure — and it’s not agreeing yet.

🔄 Flame Carryover: Confidence vs. Hesitation

Carryover is one of the biggest tells.

Here’s what I look for:

Good carryover

-

Flame travels smoothly burner to burner

-

No delay

-

No popping

-

No uneven height

Bad carryover

-

One burner hesitates

-

Flame lifts briefly before settling

-

You hear a faint “whoof” or delayed ignition sound

That hesitation often points to:

-

Marginal gas pressure

-

Dirty or misaligned burners

-

Manifold inconsistencies

-

Slight over- or under-firing conditions

You won’t catch that with a single pressure reading.

🔵 Flame Color: More Than Just Blue

Everyone says “blue flame good, yellow flame bad.”

That’s kindergarten logic.

What I’m actually watching:

-

Blue intensity

-

Orange tips during blower ramp-up

-

Color shift when inducer stabilizes

-

Flicker when cabinet pressure changes

A flame that changes color when the blower comes on is reacting to air movement, not just gas.

That tells me the system is interacting — not just burning.

🌬️ The Blower Test: Where Marginal Pressure Shows Itself

This is where behavior matters.

When the blower ramps up, I watch the flame closely.

Warning signs:

-

Flame pulls or leans

-

Height drops noticeably

-

Flame flickers or shimmers

-

Burners lose uniformity

That doesn’t automatically mean bad gas pressure — but it means pressure is marginal in relation to airflow.

This is where installers who only chase numbers get fooled.

📉 Manifold Pressure vs. Dynamic Pressure

Static readings lie politely.

Dynamic behavior tells the truth loudly.

You can have:

-

“Perfect” manifold pressure

-

And still have unstable combustion

Why?

Because real systems don’t run in a vacuum.

They run with:

-

Duct resistance

-

Return pressure

-

Vent interaction

-

Cabinet leakage

That’s why I treat gas pressure as a relationship, not a spec.

The Gas Technology Institute explains how combustion stability depends on multiple interacting variables, not just pressure alone:

https://www.gti.energy

🔥 Lifting Flames: The Quiet Warning Everyone Misses

A lifting flame is never “normal.”

Even slight lift during startup tells me:

-

Gas velocity may be too high

-

Air mix is off

-

Burner alignment isn’t ideal

-

Or the vent is influencing combustion

The worst part?

Lifting flames often settle down after a minute — which tricks installers into thinking the issue “fixed itself.”

It didn’t.

It just hid.

🧯 Flame Rollout Isn’t Always Dramatic

Everyone imagines rollout as fire shooting out of the cabinet.

Real life is quieter.

Early rollout looks like:

-

Flame curling backward slightly

-

Uneven burner face heating

-

Subtle flame distortion near the vestibule

These signs usually appear during startup, not steady state.

OSHA’s combustion safety guidance emphasizes recognizing early abnormal flame behavior before it becomes a hazard:

https://www.osha.gov

🧪 Why I Check Pressure After I Watch the Flame

I don’t ignore the manometer — I just don’t start with it.

My order:

-

Watch ignition

-

Watch carryover

-

Watch flame under blower load

-

Then measure manifold pressure

Why?

Because now I know what question I’m asking the gauge.

Instead of:

“Is this within spec?”

I’m asking:

“Does this explain what I just saw?”

That’s a completely different mindset.

🔁 Flame Behavior Over Multiple Cycles

I never trust a single ignition.

I want:

-

Cold start

-

Warm restart

-

Second cycle consistency

Marginal gas pressure often behaves on the first cycle and fails on the second.

That’s why I watch patterns — not moments.

🧾 What I Write in My Startup Notes

When it comes to gas behavior, my notes don’t just say:

“Gas pressure OK”

They say things like:

-

“Smooth carryover”

-

“Stable flame under full airflow”

-

“No lift on blower ramp”

-

“Consistent ignition across cycles”

Those notes save me months later when a homeowner says:

“It’s acting different now.”

🏠 Why Home Size, Ducts, and Venting Matter Here

Gas pressure doesn’t exist alone.

It reacts to:

-

Oversized furnaces short-cycling

-

Undersized returns choking airflow

-

Long vent runs affecting inducer performance

That’s why startup flame behavior is system feedback, not just burner feedback.

The Department of Energy has documented how installation conditions directly affect combustion efficiency and reliability:

https://www.energy.gov

🧰 Tools Matter — But Experience Reads First

Yes, I use tools.

But tools confirm. Experience interprets.

If you don’t know what “wrong” looks like in a flame, a perfect number won’t save you.

⚠️ The Biggest Gas Pressure Myth

Here it is:

“If it’s within spec, it’s fine.”

That’s how marginal systems survive startup and fail later.

Specs are boundaries — not guarantees.

The flame is the truth teller.

🔚 Jake’s Rule on Gas Pressure

If the flame looks confident,

the system usually is.

If the flame looks nervous,

something upstream is lying to you.

Gas pressure isn’t a number you chase.

It’s a behavior you understand.

And startup is the only time the system shows you its real personality — before it learns how to hide its problems.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Why Jake Lets the Furnace Fail Once on Purpose During Startup