Most furnaces don’t fail because of bad parts. They fail because of bad introductions.

I’ve started up thousands of systems, and I’ll tell you this straight: the first five minutes before power ever hits the furnace determine whether that system becomes a quiet workhorse or a callback waiting to happen.

This article isn’t about tools.

It isn’t about meters.

And it definitely isn’t about the manufacturer’s startup checklist.

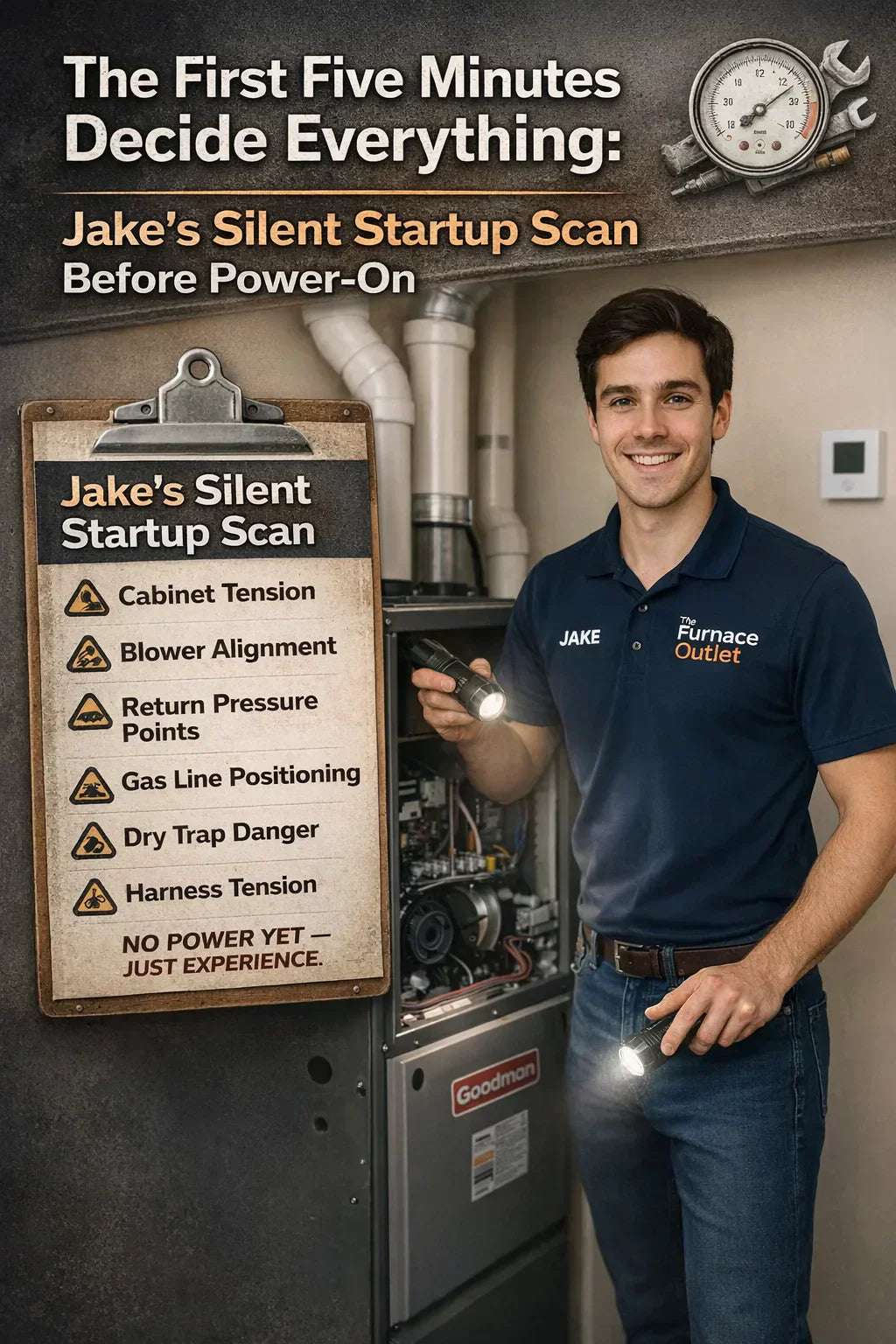

This is about the silent startup scan — the things I look at, listen for, and mentally confirm before I ever flip the switch on a high-efficiency furnace like the Goodman GR9S960803BN.

No gauges.

No readings.

Just experience.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

👀 Why Startup Begins Before Electricity

Most installers treat startup like a button press.

I don’t.

Because once power is applied, the furnace starts reacting — and when that happens, you’ve already missed your chance to prevent half the problems that show up later.

Before power, the system is honest.

After power, it’s compensating.

That’s why I slow down before ignition, especially on a 96% AFUE furnace with a tight cabinet and multi-speed blower, like this one:

🧠 Rule One: Silence Is Information

If the mechanical room is loud before startup, you’ve already got a problem.

Here’s what I’m listening for in silence:

-

Metal tension

-

Duct contact

-

Cabinet stress

-

Loose fasteners telegraphing vibration

If I bump the cabinet with my knuckles and it rings like a drum, I know something inside is going to sing once airflow starts.

Silence tells me the system is relaxed.

Noise tells me it’s already fighting itself.

📐 The Cabinet Scan: Stress Tells the Truth

High-efficiency furnaces don’t like being twisted.

Before power, I check:

-

Are the cabinet corners square?

-

Is the furnace sitting flat on the pad?

-

Are mounting screws overtightened into warped framing?

-

Is the return drop pulling sideways?

A furnace that’s under physical stress will:

-

Rattle once hot

-

Change sound after thermal expansion

-

Shift blower alignment over time

You won’t catch that with a meter.

You catch it with your eyes.

🌬️ The Return Opening Reality Check

This is where most installs quietly fail.

Before startup, I look straight into the return opening and ask one question:

Can this blower breathe freely from day one?

Warning signs:

-

Sharp-edged transitions

-

Filters bent into a “smile”

-

Panned returns that choke airflow

-

Duct liners sagging into the opening

A 9-speed blower doesn’t fix bad airflow.

It just hides it — until noise, limits, or comfort complaints show up.

🔩 Internal Fastener Reality (The “Factory Isn’t Perfect” Rule)

I don’t assume anything inside the cabinet is tight just because it came from the factory.

Before power:

-

I gently check blower mounts

-

I look for shipping-shifted brackets

-

I confirm harness routing isn’t touching sharp metal

Why?

Because once the blower ramps up, any loose component becomes a noise amplifier.

Startup is the quietest moment that furnace will ever have again.

🔥 Gas Line Posture (Not Pressure)

Everyone obsesses over gas pressure.

I don’t — not yet.

Before startup, I check posture:

-

Is the gas line supporting itself?

-

Is the valve square, not torqued?

-

Is the sediment trap actually doing its job?

-

Are fittings aligned without strain?

Gas lines under stress don’t fail immediately.

They fail after heat cycles.

Startup is when you prevent that.

💧 Condensate: Dry Is Dangerous

A high-efficiency furnace should never start dry.

Before power:

-

Trap is installed

-

Trap is primed

-

Drain line is pitched

-

No dips to hold water

A dry trap on startup causes:

-

Pressure switch confusion

-

Delayed ignition

-

Acid damage that shows up years later

This is non-negotiable.

If you want to understand why condensate management matters on 90+ furnaces, ASHRAE explains the science clearly here:

https://www.ashrae.org/technical-resources

🔌 Electrical Without Power: The Forgotten Check

I inspect wiring before it’s energized because that’s when mistakes are obvious.

I’m looking for:

-

Harness tension

-

Sharp bends near the control board

-

Low-voltage wires crossing high-voltage paths

-

Grounds that are technically connected but mechanically weak

A ground that looks “good enough” cold can become a nuisance trip when vibration starts.

NFPA’s electrical grounding guidance backs this up:

https://www.nfpa.org

🧭 Venting Alignment: Straight Beats Pretty

Before startup, I step back and trace the vent path with my eyes.

I want:

-

Straight runs

-

Proper slope

-

No forced alignment at the collar

-

No weight pulling on the inducer

If the vent needs force to fit, it’s already wrong.

Combustion appliances hate tension.

They tolerate gravity.

🛠️ The Tool Check (Yes, Tools Matter — But Not How You Think)

Before power, I verify the tools I won’t need later:

-

Combustion analyzer staged

-

Manometer zeroed

-

Thermometer ready

-

Notebook open

I don’t rush startup. I prepare for confirmation.

It’s not about gadgets — it’s about consistency.

🧾 The Mental Checklist I Never Write Down

Before I flip the switch, I silently confirm:

-

Cabinet relaxed

-

Airflow unobstructed

-

Condensate ready

-

Gas line unstressed

-

Wiring calm

-

Vent neutral

If any one of those feels off, I stop.

Because once power is applied, the furnace starts covering up mistakes — and that’s when installers fool themselves into thinking everything’s fine.

⚠️ Why Most Callbacks Are Born Before Startup

When I hear:

“It worked fine at first…”

I already know what happened.

Something marginal passed initial startup but failed under:

-

Thermal expansion

-

Vibration

-

Overnight cool-down

-

Second ignition cycle

That failure didn’t happen later.

It was introduced before power-on.

The Department of Energy has published data showing installation quality directly affects equipment longevity and efficiency:

https://www.energy.gov

🧠 Jake’s Rule of Startup

If the furnace feels calm before power,

it usually behaves after power.

If it feels rushed, tight, or forced before startup,

it will argue with you later.

The first five minutes aren’t about readings.

They’re about respect.

🔚 Final Thought: Startup Is a Conversation

Startup isn’t a command.

It’s a conversation between you and the system.

If you listen before you speak,

the furnace usually tells you everything you need to know.

And if you skip that moment?

You’ll hear from it later — usually at 2 a.m.,

when the homeowner’s cold

and your phone’s ringing.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Gas Pressure Isn’t a Number — It’s a Behavior: How Jake Reads Flame Personality on Startup