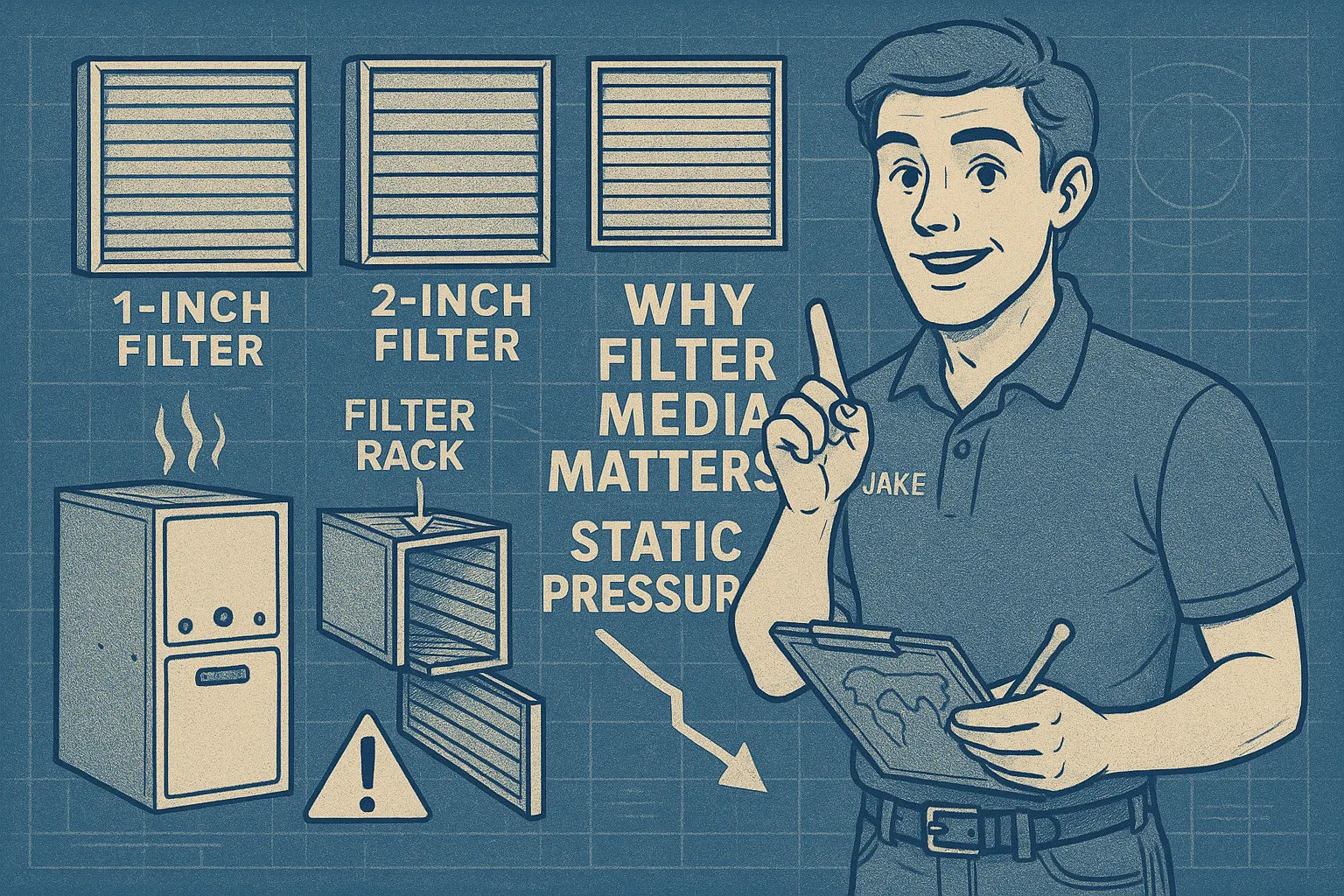

Introduction: The Filter Is the First Restriction—And Usually the Worst

Jake says this on every job:

“If your filter is wrong, your entire HVAC system is wrong.”

Homeowners think filters are simple:

-

Swap them once in a while

-

Pick a MERV rating

-

Buy whatever is on sale

But Jake has seen the damage the wrong filter can cause:

-

screaming ECM blowers

-

hot/cold room imbalance

-

furnace overheating

-

high static pressure

-

whistling returns

-

1st vs 2nd floor temperature fights

-

short cycling

-

failed heat exchangers

And in nearly every case?

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

The problem starts right at the filter rack.

In this article, Jake breaks down the real airflow science behind 1-inch, 2-inch, and 4-inch filters — and explains which one wins for:

-

static pressure

-

blower health

-

temperature rise

-

noise

-

two-stage comfort

-

ECM motor efficiency

-

long-term system performance

Let’s go to battle.

🧱 1. The Filter Isn’t an Accessory — It’s the First Airflow Gatekeeper

Jake explains it like this:

“Air doesn’t start at the blower. It starts at the filter.”

The furnace cannot breathe until:

-

return air passes through the grille

-

return duct funnels it

-

filter media cleans it

-

furnace accepts it through the blower

Most systems fail at step 3: the filter media.

Why? Because filter thickness controls:

-

air velocity (how fast air hits the media)

-

pressure drop (how hard air is to pull through)

-

surface area (how much filter there is to breathe through)

-

ECM motor workload

-

temperature rise stability

-

coil performance

-

noise

Jake sees it every day:

A poorly designed filter setup will choke even the best furnace.

A properly designed one will transform a system.

And the winner — by a landslide — is always the filter with the largest media surface area.

🔥 2. The 1-Inch Filter Problem: Jake’s “Never Use These on a 96% Furnace” Rule

Jake does NOT use 1-inch filters on:

-

96% AFUE furnaces

-

two-stage furnaces

-

ECM blower systems

-

multi-story homes

-

high-static duct systems

-

tight mechanical rooms

-

long branch runs

Why?

Reason 1 — Surface area is tiny

Even with pleats, a 1-inch filter simply cannot provide enough area to keep velocity low.

Reason 2 — Static pressure skyrockets

Most 1-inch MERV 8 filters add:

-

0.20–0.35 inches of static WHEN CLEAN

-

0.40–0.60 inches when partially dirty

-

0.70–1.0+ inches when clogged

Jake’s rule:

“The moment a 1-inch filter gets dusty, your furnace gets loud.”

Reason 3 — Velocity noise increases

High velocity = loud airflow.

This causes:

-

hissing

-

whistling

-

grille rumble

-

return pull noise

Reason 4 — Heat exchanger stress

Low airflow = high temperature rise.

High temperature rise = furnace stress.

Jake has seen furnaces go from a stable 35°F rise to a dangerous 65–75°F rise simply because of a 1-inch filter.

Reason 5 — Bad for two-stage furnaces

Stage 1 airflow becomes:

-

weak

-

uneven

-

loud

Stage 2 becomes:

-

too hot

-

too fast

-

overfiring

Two-stage comfort disappears.

⚠️ 3. The 2-Inch Filter Myth: Better Than 1-Inch, But Still a Compromise

Jake uses 2-inch filters only when:

-

the furnace room is tight

-

the return drop has no depth

-

the customer won’t rebuild the return platform

-

the blower is ECM and static is already decent

2-inch filters provide:

-

more surface area

-

lower velocity

-

better dust loading

-

quieter operation

But Jake is blunt:

“A 2-inch filter is a Band-Aid, not a fix.”

Their problems:

1. They still load fast

Every inch of media matters.

A 2-inch filter fills up far quicker than a 4-inch.

2. Pressure drop is still too high for many duct systems

Typical static added:

-

0.12–0.20 inches

Better than 1-inch, but still too high for homes with: -

long duct runs

-

small returns

-

high-MERV preferences

-

older duct systems

3. Still causes noise in high-MERV versions

A 2" MERV 13 is almost as restrictive as a 1" MERV 11.

Jake sees this a lot.

Verdict: 2-inch filters are “better,” but not ideal.

They will not solve the deeper airflow restrictions in most homes.

🥇 4. The 4-Inch Filter Advantage: Jake’s Gold Standard for 96% Furnaces

This is Jake’s standard for every two-stage furnace he installs.

Why 4-inch filters win:

A. MASSIVE surface area

More surface area = lower velocity = lower resistance.

This keeps:

-

ECM blower quiet

-

airflow stable

-

temperature rise predictable

-

Stage 1 operation dominant

B. Extremely low pressure drop

Most 4-inch filters add:

-

0.05–0.10 inches of static pressure

That is a huge improvement over:

-

1-inch: 0.20–0.35”

-

2-inch: 0.12–0.20”

Jake calls this:

“The difference between breathing through a straw and breathing through a snorkel.”

C. Ideal for two-stage furnaces like the Goodman GR9T96

Two-stage furnaces run longer Stage 1 cycles.

Stage 1 airflow must be:

-

gentle

-

quiet

-

smooth

-

unrestricted

A 4-inch filter protects low-stage comfort.

D. Keeps ECM blower RPM low

ECM motors compensate for restrictions by increasing RPM.

This increases:

-

noise

-

wear

-

watt usage

Lower static = lower RPM = long motor life.

E. Perfect for homes with pets, allergies, or dust

4-inch filters hold 4–6x more dust than 1-inch filters.

Most homeowners forget to replace 1-inch filters.

A 4-inch MERV 11 or MERV 13 holds enough dust to last 6–12 months without drastically increasing static pressure.

📊 5. The Science: Surface Area vs. MERV Rating (Jake’s Core Rule)

Homeowners obsess over MERV rating.

Jake obsesses over surface area.

Jake’s rule:

“A big MERV number means nothing if the filter has no area to breathe through.”

A 4-inch MERV 13 often has lower static pressure than a 1-inch MERV 8 because the surface area is so much larger.

This is why he picks:

-

4-inch > MERV 13

-

2-inch > MERV 11

-

1-inch > MERV 8 or lower only in emergencies

📉 6. Static Pressure Battle: 1-inch vs. 2-inch vs. 4-inch

Jake’s real-world numbers (averages):

1-inch filter

-

Clean: 0.20–0.35"

-

Lightly dirty: 0.40–0.60"

-

Dirty: 0.60–1.00+"

2-inch filter

-

Clean: 0.12–0.20"

-

Dirty: 0.30–0.45"

4-inch filter

-

Clean: 0.05–0.10"

-

Dirty: 0.10–0.20"

Jake explains:

“Your system’s static pressure should be 0.40–0.50” total.

One 1-inch filter can ruin that by itself.”

🔧 7. Filter Racks vs. Filter Cabinets — Jake’s Mandatory Upgrade

Jake replaces:

-

cheap 1-inch slide-in racks

-

flimsy spring clips

-

leaky frames

-

bent filter rails

Because they cause:

-

bypass airflow

-

turbulence

-

filter warping

-

noise

-

dust accumulation inside blower

-

higher static

Jake installs:

Sealed 4-inch media cabinets

These create:

-

a flush, airtight seal

-

smooth airflow transition

-

evenly distributed intake pressure

-

quiet blower intake

A proper cabinet reduces static by 0.05–0.15” alone.

🔇 8. Filter Choice and System Noise: Jake’s Quiet System Method

Jake finds noise problems tied to filters in 90% of homes.

1-inch filters = loudest systems

High velocity → hissing and whooshing.

2-inch = moderate

Lower noise but still insufficient in high-static systems.

4-inch = whisper quiet

Why?

-

more surface area

-

smoother airflow

-

blower RPM lower

-

return turbulence reduced

This is how Jake designs silent systems.

❄️ 9. How Filter Choice Affects Temperature Balance Across Rooms

High static = low airflow = cold/different rooms.

Jake improves room balance by:

-

reducing static

-

improving CFM to long runs

-

stabilizing coil airflow

-

maximizing Stage 1 runtime

Upstairs Bedrooms

These benefit the most because:

-

they require more airflow

-

ducts are longer

-

risers have pressure loss

Jake sees 20–30% more airflow to second floors after switching to 4-inch media.

🛠️ 10. Maintenance Reality: Why Homeowners Murder 1-Inch Filters

Jake sees filters unchanged for 6–12 months.

A 1-inch filter must be changed every 30 days.

That never happens.

So Jake designs systems that forgive the homeowner:

-

4-inch = replace every 6–12 months

-

2-inch = replace every 60–90 days

Lower maintenance + better airflow = homeowner win.

📦 11. When Jake Recommends Each Filter Thickness

1-inch Filter

Jake’s answer: NEVER

Except:

-

temporary fix

-

legacy systems

-

old 80% furnaces on PSC blowers

2-inch Filter

Use only when:

-

cabinet depth limited

-

customer refuses return rebuild

-

moderate static systems

4-inch Filter

Use ALWAYS when:

-

96% furnaces

-

two-stage heating

-

ECM blower

-

multi-floor homes

-

filters replaced infrequently

-

homeowners want quiet airflow

Perfect match for:

-

Goodman GR9T96

-

any two-stage Goodman

🧪 12. Jake’s Step-by-Step Filter Upgrade Method

When Jake arrives at a home with airflow complaints:

Step 1 — Measure static pressure

Aim for 0.40–0.50" total.

Step 2 — Inspect filter rack

Bad? Replace it.

Step 3 — Install 4-inch media filter

Always a cabinet, never a slide-in.

Step 4 — Fix return geometry

Add or widen returns.

Step 5 — Reduce turbulence near blower

Correct transitions, elbows, or drop box.

Step 6 — Adjust blower speed

Lower RPM in Stage 1 if static improves.

Step 7 — Balance system

Adjust takeoffs and dampers.

Jake consistently sees static drop by:

0.20–0.40 inches after an upgrade.

🧪 13. Real-Home Case Study: The 1-Inch Filter That Destroyed Comfort

Home:

2,300 sq ft, two-story

Furnace: Goodman GR9T96

Symptoms:

-

loud airflow

-

cold upstairs

-

1-inch MERV 11 filter

-

static = 0.92"

-

ΔT = 67°F

-

Stage 2 running constantly

Installer recommended upsizing the furnace.

Jake disagreed.

Jake’s Fix:

-

replaced rack

-

installed 4-inch media cabinet

-

added 20x25 return

-

smoothed return transition

Results:

-

static = 0.92" → 0.44"

-

ΔT stabilized at 38°F

-

Stage 1 operation = 85%

-

noise dropped 50%

-

second floor warmed evenly

Jake saved the system — no new furnace needed.

🔗 14. Verified External Sources

-

DOE Furnace Efficiency Guidelines

https://www.energy.gov/energysaver/furnaces-and-boilers -

ASHRAE Airflow Standards

https://www.ashrae.org -

SMACNA Duct Construction Rules

https://www.smacna.org - Goodman Technical Literature

🎯 Conclusion: The Filter Determines Everything

Jake ends every filter conversation with this:

“Your filter decides how loudly the system runs, how evenly rooms heat, how long the furnace lives, and how well your two-stage system performs.”

In Jake’s world:

-

4-inch wins

-

2-inch is acceptable

-

1-inch is the enemy

This is the definitive guide to filtration for modern 96% AFUE furnaces — especially the Goodman GR9T96.

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic we will know more about: Jake’s Checklist for a Perfect Two-Stage Install: Thermostat, Dip Switches, Timing, Blower Speed & More