Jake has commissioned hundreds of two-stage furnaces — Goodman, Amana, Trane, Lennox, Carrier, Rheem, every brand under the sun. And no matter the brand, he keeps finding the same problem:

“Most two-stage furnaces installed in America are accidentally turned into single-stage units.”

Not because the equipment is bad.

Not because the home is wrong.

Not because the homeowner bought the wrong size.

But because:

-

the thermostat isn’t compatible

-

W2 isn’t wired

-

dip switches are left on factory defaults

-

blower speeds aren’t matched to the duct system

-

the timing logic conflicts with airflow

-

static pressure forces Stage 2 early

-

installers never commission the system

-

shortcuts collapse two-stage performance

So the system:

-

never runs Stage 1

-

overheats

-

short cycles

-

becomes loud

-

blasts air unevenly

-

ramps the ECM blower unnecessarily

-

and frustrates the homeowner

Jake’s mission: unlock the full potential of the two-stage system — smooth, quiet, invisible comfort.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

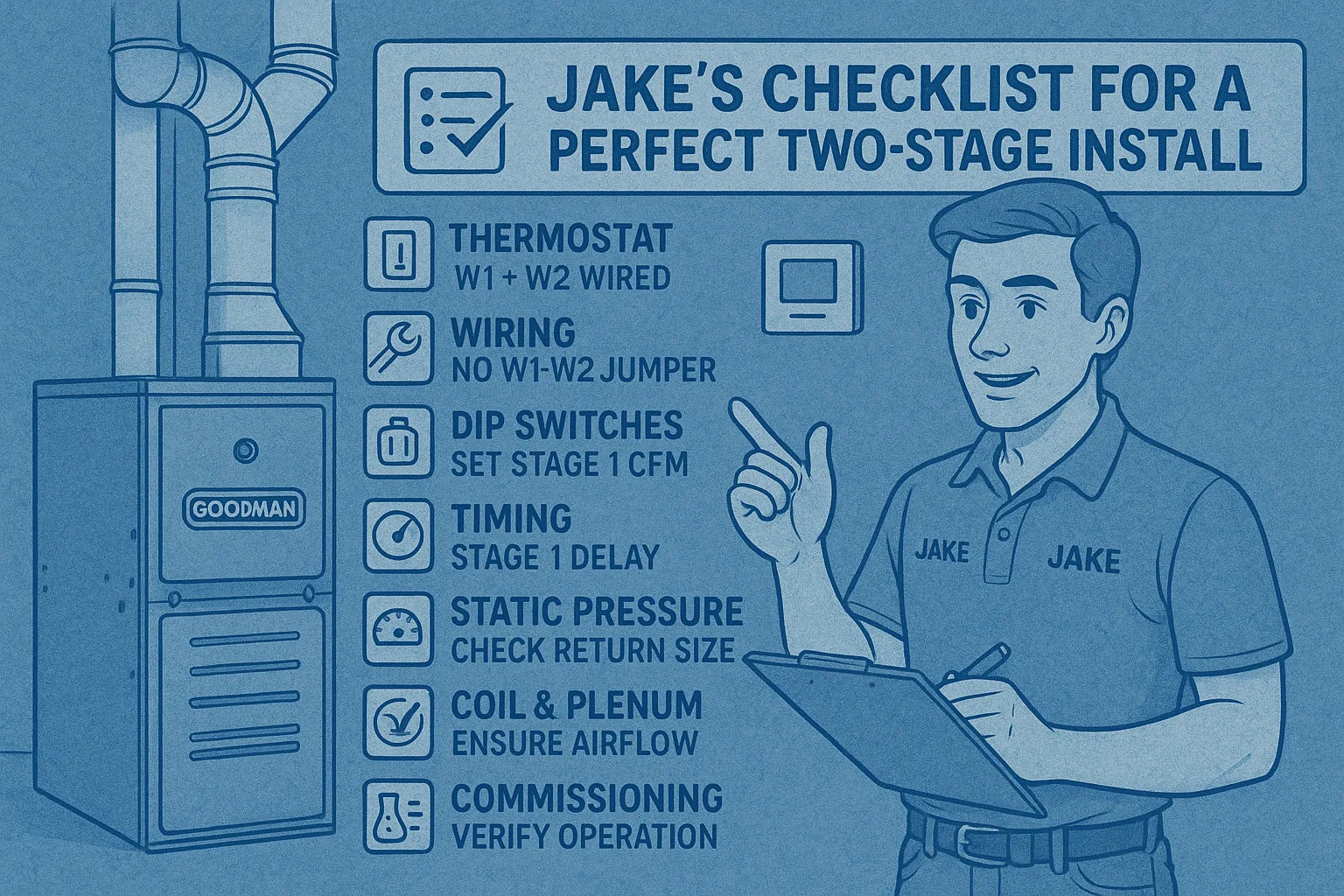

This article is Jake’s complete, step-by-step commissioning blueprint for a perfect two-stage install.

🧱 1. Why Most Two-Stage Systems Run Like Single-Stage Systems

Jake sees installers make the same mistakes over and over:

✔️ W2 not wired

The furnace never receives a second-stage call, so it defaults to timing logic or never uses Stage 2 at all.

✔️ Thermostat only supports single-stage

The homeowner thinks they’re getting two-stage comfort — but the stat can’t command it.

✔️ W1–W2 jumpers left in place

This locks the furnace into one-stage behavior.

✔️ Dip switches left on factory default

Which typically means:

-

too much airflow in Stage 1

-

too much airflow in Stage 2

-

overly aggressive heating

-

high noise

-

uneven comfort

✔️ Blower not matched to duct capacity

High static pressure kills Stage 1.

✔️ Filter or return restricts airflow

Causes:

-

high ΔT

-

overheating

-

forced Stage 2

-

noisy operation

Jake’s rule:

“A two-stage furnace will only behave if the installer behaves.”

🎛️ 2. Thermostat Compatibility: Jake’s Staging Pass/Fail Map

A thermostat is the brain of a two-stage system.

If the brain cannot command W2, it cannot “speak” Stage 2.

Jake uses three categories:

Category A — TRUE Two-Stage Thermostats (Pass)

These have dedicated W1 + W2 terminals and true multistage logic.

Jake recommends:

✔️ Honeywell T6, T9, T10

Affordable, reliable, clean staging behavior.

✔️ Ecobee Premium & Ecobee Enhanced

Full W1/W2 support, excellent temperature averaging.

✔️ Emerson Sensi Touch

Simple interface, dependable staging.

Category B — “Pseudo Two-Stage” Thermostats (Fail)

These thermostats pretend to support staging but actually rely on timing algorithms, NOT real W2 calls.

Jake avoids:

-

cheap Wi-Fi stats

-

single-stage Nest models

-

off-brand Amazon units

-

thermostats with “adaptive intelligence” but no W2 terminal

Jake’s rule:

“If it doesn’t have a W2 terminal, it doesn’t have my respect.”

Category C — Communicating Stats (Conditional Pass)

These only work if:

-

the furnace is a communicating model

-

wiring and control board support it

-

the entire system is matched

Jake prefers non-communicating two-stage stats for simplicity on GR9T96-style installs.

🧰 3. Wiring: The Smallest Mistakes That Kill Two-Stage Performance

Jake checks the thermostat wiring before he checks ANYTHING else.

✔️ W1 → furnace W1

Primary heat call.

✔️ W2 → furnace W2

Second-stage call — THE MOST IMPORTANT WIRE.

✔️ NO W1–W2 JUMPERS

Jake finds these constantly.

They force Stage 2 instantly.

✔️ Y1 → cooling

Ensures correct blower profiles.

✔️ G → fan

Fan-only logic must be correct.

✔️ C wire → stable power

Especially for smart stats.

Jake’s rule:

“You can’t fix staging until you fix the wiring.”

🧲 4. Dip Switches: The Secret Menu That Controls Everything

Most installers NEVER touch dip switches.

Jake touches them EVERY TIME.

On the Goodman GR9T96, dip switches control:

Heating Airflow (H1–H6)

-

CFM profile

-

Stage 1 vs Stage 2 airflow

-

fan-off timing

-

airflow ramps

Jake sets:

-

Stage 1: LOW–MED

-

Stage 2: MED–HIGH

He never sets Stage 1 too high because it:

-

makes heat feel cool

-

becomes noisy

-

overdrives ductwork

-

kills comfort

Cooling Airflow (C1–C6)

Only matters for matched cooling systems — but still important.

Blower Off Delay (OD1–OD4)

Controls how long the blower runs after heat shuts off.

Jake’s setting:

-

90–120 seconds

This extracts remaining heat without blowing cold air.

Staging Timing & Logic Controls

-

minimum runtime

-

cooling interlocks

-

staging delay

Jake starts with a 10–12 minute delay before Stage 2.

🌬️ 5. Blower Speed Configuration: Jake’s CFM Rules for Quiet Comfort

Jake matches blower speed to:

-

duct size

-

static pressure

-

number of returns

-

filter type

-

coil resistance

He does NOT use factory-default blower settings.

✔️ Stage 1: 60–70% of max CFM

This creates:

-

low noise

-

smooth airflow

-

consistent temperature

-

long heating cycles

✔️ Stage 2: full CFM output

Used only for:

-

extreme cold spells

-

large temperature deltas

-

quick recovery

-

end-of-cycle heat distribution

Jake’s rule:

“Stage 2 is a tool — Stage 1 is a lifestyle.”

📈 6. Timing: How Long Each Stage Should Run (Jake’s Magic Numbers)

Jake uses timing to prevent the furnace from jumping to Stage 2 too fast.

✔️ Minimum Stage-1 runtime:

10–12 minutes

This prevents:

-

short cycling

-

noisy ramps

-

hot/cold swings

-

overly aggressive heating

✔️ Stage-2 eligibility only when:

-

temperature hasn’t risen enough

-

thermostat calls for more

-

outdoor temperature is extremely low

-

duct system can handle higher CFM

Jake NEVER allows Stage 2:

-

during mild weather

-

when static is above 0.60"

-

when return ductwork is undersized

-

when the home is within 1–2°F of setpoint

This is comfort engineering.

📉 7. Static Pressure & Return Design: The Triad of Staging Success

Jake’s three key staging metrics:

✔️ Return Air Volume

If returns are too small → Stage 1 becomes loud and weak.

✔️ Filter Restriction

1-inch filters → Stage 1 suffocates

4-inch filters → Stage 1 blossoms

✔️ Static Pressure

Jake’s thresholds:

-

0.40–0.50" ideal

-

0.60" = staging problems

-

0.80" = system choking

-

1.00+" = furnace in distress

If static is too high, the furnace:

-

overheats

-

ramps blower

-

jumps to Stage 2

-

short cycles

-

becomes loud

Fixing static is often the key to unlocking staging.

🧊 8. Coil & Plenum Alignment: The Hidden Reason Staging Fails

Bad airflow at the coil = failed staging.

Jake checks:

-

coil sits flat

-

coil sits centered

-

plenum height at least 18–24"

-

no coil bypass

-

no return turbulence

-

no kinks or sharp transitions

Even perfect staging at the board is doomed if the coil is starved.

Jake’s rule:

“Staging loves low static and tall plenums.”

🔥 9. Combustion Air & Venting: The Invisible Staging Breaker

If the furnace cannot breathe, Stage 2 will:

-

trigger rollout

-

trip the pressure switch

-

lock out the burner

-

shut down

Jake checks:

-

intake air path

-

vent length

-

elbow count

-

proper slope

-

no blockages

-

correct PVC diameter

Staging depends on proper combustion.

🧪 10. Jake’s Complete Two-Stage Commissioning Test

Jake performs these tests in this exact order:

1. Static Pressure Measurement

Before touching anything else.

2. Filter Check

Replace 1-inch filters immediately.

3. Dip Switch Settings

Heating airflow + off-delay.

4. Wiring Verification

Ensure W1/W2 are clean.

5. Thermostat Configuration

Set correct type (2H/1C conventional).

6. CFM Verification

Check airflow tables against measured static.

7. Test Stage 1 Operation

Should be silent, smooth, stable.

8. Test Stage 2 Operation

Only after Stage 1 stabilizes.

9. Measure Temperature Rise

Must fall within furnace spec:

30–60°F for most GR9T96 units

10. Combustion Analysis

Check CO levels, vent performance, draft.

11. Duct Balance Check

Adjust supply/return balance.

12. Full Cycle Operation Test

Verify Stage 1 dominates.

Jake does not sign off on a furnace until Stage 1 feels “buttery smooth.”

🛠️ 11. Real-Home Case Study: The “Two-Stage Furnace That Wasn’t”

Home:

3,000 sq ft — two-story

Furnace: Goodman GR9T96

Thermostat: single-stage WiFi model

Symptoms:

-

loud airflow

-

cold upstairs bedrooms

-

high-limit trips

-

Stage 2 always active

-

ΔT swinging between 30 and 67°F

-

static = 0.82"

-

noisy blower ramping

Homeowner was told:

“You bought the wrong furnace.”

Jake discovered:

-

W2 not wired

-

stat didn’t support staging

-

dip switches on factory settings

-

1-inch MERV 11 filter

-

small return grille

-

coil misaligned

Jake’s Fix:

-

installed Honeywell T6

-

wired W2 correctly

-

set 12-minute Stage 2 delay

-

changed blower profiles

-

installed 4-inch filter cabinet

-

added 12x25 return

-

realigned coil

Results:

-

static dropped to 0.44"

-

ΔT stabilized at 40°F

-

Stage 1 handled 90% of heating

-

noise reduced 50%

-

upstairs now even with downstairs

Jake saved the system without replacing the furnace.

🔗 12. Verified External Sources (6)

-

DOE Residential Furnace Essentials

https://www.energy.gov/energysaver/furnaces-and-boilers -

ASHRAE Residential HVAC Standards

https://www.ashrae.org -

SMACNA Air Distribution Construction Standards

https://www.smacna.org

🎯 Conclusion: A Two-Stage Furnace Is Only as Good as Its Setup

Jake ends every commissioning with this:

“Two-stage comfort doesn’t come from the furnace — it comes from the installer.”

A perfect two-stage setup gives homeowners:

-

whisper-quiet airflow

-

reduced energy bills

-

even temperatures room-to-room

-

long Stage-1 cycles

-

smooth, gentle heat

-

long furnace lifespan

-

stable temperature rise

-

happier ECM blower

This is the real blueprint for two-stage mastery — Jake’s complete method, from wiring to CFM to final commissioning.