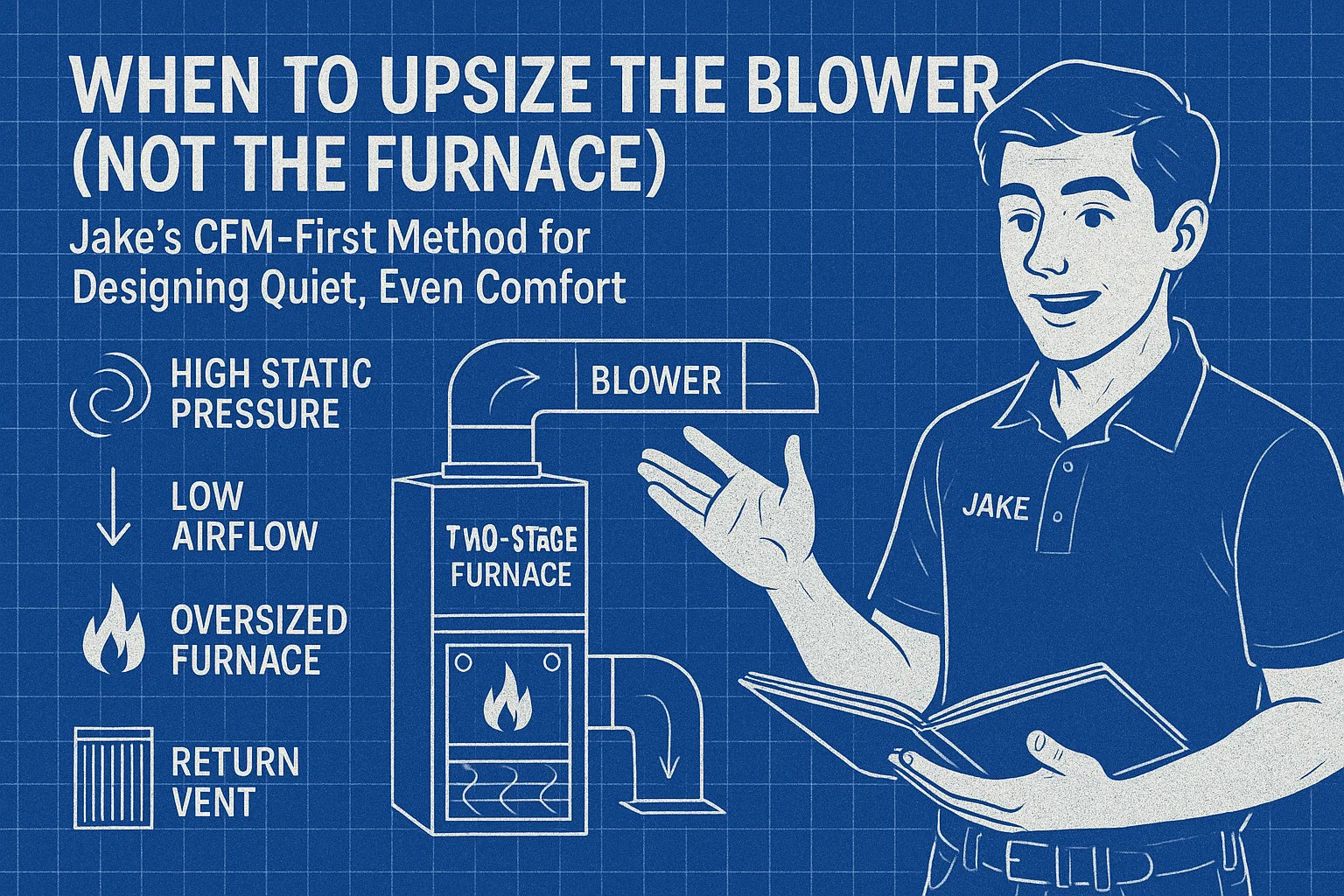

📘 Introduction: Why Jake Says “Your Furnace Isn’t the Problem — Your Airflow Is.”

Jake has been in more furnace rooms than he can count.

Basements. Attics. Crawlspaces. Tight closets where he needs to breathe in just to shut the door.

And the pattern is always the same:

Homeowners say:

-

“My furnace isn’t big enough.”

-

“The upstairs is cold.”

-

“The system is loud.”

-

“The airflow is weak.”

-

“The furnace keeps cycling.”

Installers say:

-

“You need to upsize the furnace.”

-

“Your home needs more BTUs.”

-

“This system is too small for two stories.”

Jake says:

“No. The furnace is fine.

The blower isn’t.”

In 80% of homes Jake evaluates — BTUs are not the issue.

The blower CFM, return air volume, duct geometry, and static pressure are.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

This long-form blueprint explains Jake’s CFM-First Method, the exact approach he uses to determine when a home needs a bigger blower, NOT a bigger furnace.

This protects:

-

the heat exchanger

-

the ECM motor

-

temperature rise

-

static pressure

-

two-stage comfort

-

system noise

-

long-term efficiency

And it saves homeowners thousands by avoiding unnecessary furnace replacements.

🧱 1. The Myth of “Undersized Furnaces”: Why BTUs Aren’t the Problem

Jake explains it like this:

“Homes almost never lack heat. They lack airflow.”

Most modern 96% AFUE furnaces — especially units like the Goodman GR9T96 — are oversized for 90% of homes.

Why undersized furnaces are rare:

-

Most homes have old ductwork built for 80% units (high capacity).

-

Most Manual J loads are 30–50% overestimated.

-

Most furnaces sold today are oversized by one or two BTU tiers.

-

High-efficiency furnaces have:

-

two-stage burners

-

ECM blowers

-

high modulation

-

wide BTU bandwidth

-

But airflow?

That’s where everything falls apart.

Jake finds:

-

return ducts too small

-

supply trunks too short

-

1" filters choking airflow

-

risers undersized

-

plenums too shallow

-

ECM blowers ramping hard

-

static pressure > 0.60"

When airflow is bad, rooms are uncomfortable — and homeowners assume the furnace is weak.

It isn’t. The blower can’t get heat into the rooms.

🌬️ 2. Jake’s CFM-First Method: The Real Measure of Furnace Performance

Jake always starts with airflow (CFM) — NOT BTUs.

His method:

STEP 1 — Determine total CFM requirement

Rule of thumb:

-

400–450 CFM per ton of cooling

-

30–55°F temperature rise for heating

-

balanced airflow per room

A 100,000 BTU GR9T96 typically needs:

-

1000–1400 CFM depending on staging and duct design.

STEP 2 — Measure duct capacity

Most duct systems can only handle:

-

700–900 CFM

But furnaces NEED more than that.

When ducts choke, blower ramps to compensate.

When blower ramps:

-

noise increases

-

heat exchanger overheats

-

comfort drops

STEP 3 — Match blower to duct reality

Jake doesn’t size blower based on furnace. He sizes it based on duct system limitations.

This is why a larger blower (higher tonnage motor or higher CFM setting) often fixes comfort issues without touching BTUs.

🔥 3. Furnace vs. Blower: What Each Part Actually Does

The FURNACE produces heat

Measured in:

-

BTUs

-

efficiency

-

stage output

-

temperature rise

The BLOWER delivers the heat

Measured in:

-

CFM

-

static pressure

-

blower RPM

-

ECM torque

Jake summarizes it like this:

“A furnace makes heat. A blower decides where it goes.”

If airflow fails:

-

upstairs rooms stay cold

-

long duct runs starve

-

first-floor rooms overpower

-

the system gets loud

-

Stage 1 never feels warm

-

furnace overheats

Upsize the blower → all problems above disappear.

🚨 4. Signs You Need a Bigger Blower — NOT a Bigger Furnace

Jake’s field checklist:

A. Some rooms always get less airflow

Especially:

-

upstairs bedrooms

-

long-run ducts

-

bonus rooms

-

rooms over garages

B. High static pressure (above 0.60")

Measured at the furnace using:

-

pressure ports

-

Magnehelic gauge

-

digital manometer

High static = airflow starvation.

C. Stage 2 runs too often

The GR9T96 is designed for long Stage-1 cycles.

Short Stage-2 cycles = airflow issue.

D. Blower is loud — whooshing or roaring sound

This means the ECM motor is compensating.

E. Furnace overheats / trips high limit

This is always lack of airflow — not lack of BTUs.

F. Temperature rise is above spec

Goodman temperature rise range: typically 30–60°F.

If ΔT > 60°F:

→ increase airflow

→ or lower static

→ or upsize blower

G. Weak airflow from supply registers

Common in 2-story homes and attics.

H. Short cycles, especially in mild weather

Low airflow causes rapid overheating.

If you check ANY of these boxes → blower upsizing is likely the fix.

⚙️ 5. How Jake Chooses the Right Blower Size for the Goodman GR9T96

The GR9T96 includes a 9-speed ECM blower with defined CFM outputs based on external static pressure.

But Jake never uses the furnace manual alone.

He uses real static conditions of the actual home.

Jake analyzes:

-

return duct size

-

supply trunk dimensions

-

plenum shape

-

coil resistance

-

filter type

-

actual static pressure

-

riser length

-

room-by-room CFM needs

Then he selects blower profiles that:

-

reduce noise

-

maintain low temperature rise

-

maximize Stage 1 time

-

evenly distribute airflow

-

match duct capacity

Sometimes this means using a higher-tonnage blower on a furnace that didn’t change BTUs.

Example:

-

Furnace = 100k BTU

-

Old blower = 2.5-ton equivalent

-

New blower = 3-ton equivalent

BTUs unchanged → airflow improved dramatically.

🌀 6. When a Higher-Tonnage Blower Fixes Comfort Instantly

Scenario 1 — 2-Story Home with Weak Upstairs Airflow

Long vertical risers kill airflow.

A stronger blower overcomes:

-

static pressure

-

vertical lift

-

duct friction

Scenario 2 — Long Branch Runs

20–40 ft duct runs often starve.

Bigger blower feeds distant rooms.

Scenario 3 — Supply/Return Restrictions

If the ducts cannot be opened easily, blower upsizing compensates for design flaws.

Scenario 4 — High-Static Coils

Modern coils have higher resistance.

Bigger blower keeps airflow stable.

Scenario 5 — High MERV Filters

MERV 11–13 filters increase pressure drop.

A stronger blower keeps CFM consistent.

Scenario 6 — Large Square Footage with Small Ducts

Older homes often have undersized trunks.

Blower upsizing extends airflow reach.

🔈 7. The Noise Factor: Why the Smallest Blower Is Often the Loudest

Jake explains:

“A small blower at full speed is louder than a big blower at low speed.”

Small blower = high RPM = loud.

Bigger blower = low RPM = quiet.

Why?

ECM motors get loud when they fight static.

A larger blower can move 1200–1400 CFM at a lower RPM, reducing:

-

register noise

-

whistling

-

duct vibration

-

furnace rumble

-

fan surge

Jake routinely sees a 40–60% noise reduction after increasing blower CFM capacity.

🌡️ 8. Temperature Rise: Why Blower Upsizing Protects the Heat Exchanger

Every furnace has a required ΔT (temperature rise) range.

The GR9T96 typically requires:

-

30–60°F rise

Too high = overheating

Too low = insufficient heat transfer

Jake uses a bigger blower to:

-

lower ΔT

-

reduce exchanger stress

-

reduce internal furnace temperature

-

prolong life of heat exchanger

-

reduce Stage-2 dependency

Too many installers upsize the furnace when:

👉 The ΔT problem is actually an airflow problem.

👉 And airflow problems are blower-related.

🔩 9. Static Pressure: The Real Enemy of Furnace Comfort

Static pressure destroys:

-

ECM blower efficiency

-

two-stage heating performance

-

quiet airflow

-

duct balance

-

coil performance

-

comfort consistency

Jake’s diagnostic:

0.40"–0.50" → Good

0.60"–0.70" → Restrictive

0.80"–1.00+" → System choking

When static is high:

-

blower ramps

-

system gets loud

-

supply air weakens

-

furnace overheats

Jake uses blower upsizing AFTER fixing:

-

returns

-

plenums

-

filters

-

takeoffs

-

duct geometry

A bigger blower on a system with high static without fixing ducts will:

-

just ramp harder

-

get louder

-

push static even higher

Hence Jake’s rule:

“Fix the ducts first — then adjust the blower.”

🏢 10. Multi-Story Homes: Why Blower Upsizing Makes the Biggest Difference

Second floors struggle because:

-

air rises naturally

-

supply ducts are longer

-

pressure at riser base is lower

-

static increases with vertical lift

Jake often upsizes blowers on multi-story homes to:

-

push more CFM upstairs

-

balance the floors

-

allow Stage 1 to reach the second story

-

eliminate temperature gaps

-

reduce furnace runtime

-

reduce noise downstairs

Stage 1 is where two-stage furnaces shine — but only if the blower can lift the air.

🧯 11. When NOT to Up-Size the Blower

Jake is very strict about this list.

Do NOT upsize the blower if:

1. Return ducts are too small

A bigger blower will cause suction noise and whistle.

2. Filter rack is restrictive

This increases static pressure.

3. Supply trunk is undersized

Can cause register blast.

4. Coil is mismatched

Improper refrigerant performance.

5. Ducts leak excessively

Airflow increases leakage losses.

6. Static is above 0.80"

Fix ducts before blower.

Jake says:

“The blower should never compensate for duct design mistakes — only enhance a fixed system.”

🧪 12. Real-Home Case Study: The “Too Small Furnace” That Only Needed a Bigger Blower

Home:

2,400 sq ft — two story

Furnace: Goodman GR9T96 (100k BTU)

Blower: 2.5-ton airflow setting

Symptoms:

-

cold guest room

-

roaring noise in main hallway

-

Stage 2 frequently engaged

-

temperature rise soared to 63°F

-

high-limit trips during long cycles

-

static pressure: 0.82"

Installer recommendation:

“You need a 120k BTU furnace.”

Jake’s recommendation:

“No, you need a bigger blower.”

✔️ Jake’s Fix:

-

upgraded blower tonnage profile

-

installed 4" media filter

-

added second return

-

widened coil transition

-

reduced static from 0.82" → 0.48"

✔️ Final Results:

-

ΔT stabilized at 40°F

-

Stage 1 used 90% of heating time

-

upstairs airflow increased by 27%

-

noise dropped by nearly 50%

-

no furnace upsizing required

Homeowner saved thousands

and achieved true two-stage comfort.

🔗 13. Verified External References

-

DOE Furnace Efficiency Guidelines

https://www.energy.gov/energysaver/furnaces-and-boilers -

ASHRAE Airflow Standards

https://www.ashrae.org -

SMACNA Duct Construction Rules

https://www.smacna.org - Goodman Technical Literature

🎯 Conclusion: Upsize the Blower — Not the Furnace

Jake ends every consultation with one core principle:

“Comfort comes from airflow, not BTUs.”

A bigger furnace rarely fixes comfort.

A bigger blower almost always does.

Jake’s CFM-First Method ensures:

-

smoother Stage-1 heat

-

quieter ECM performance

-

lower static pressure

-

better coil efficiency

-

more balanced rooms

-

longer equipment life

-

true two-stage comfort

This is how modern heating comfort is designed.

Not with heat.

With airflow.

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic we will know more about: Why Filter Media Matters: Jake’s Battle Between 1-Inch, 2-Inch & 4-Inch Filters—And Who Wins for Static Pressure