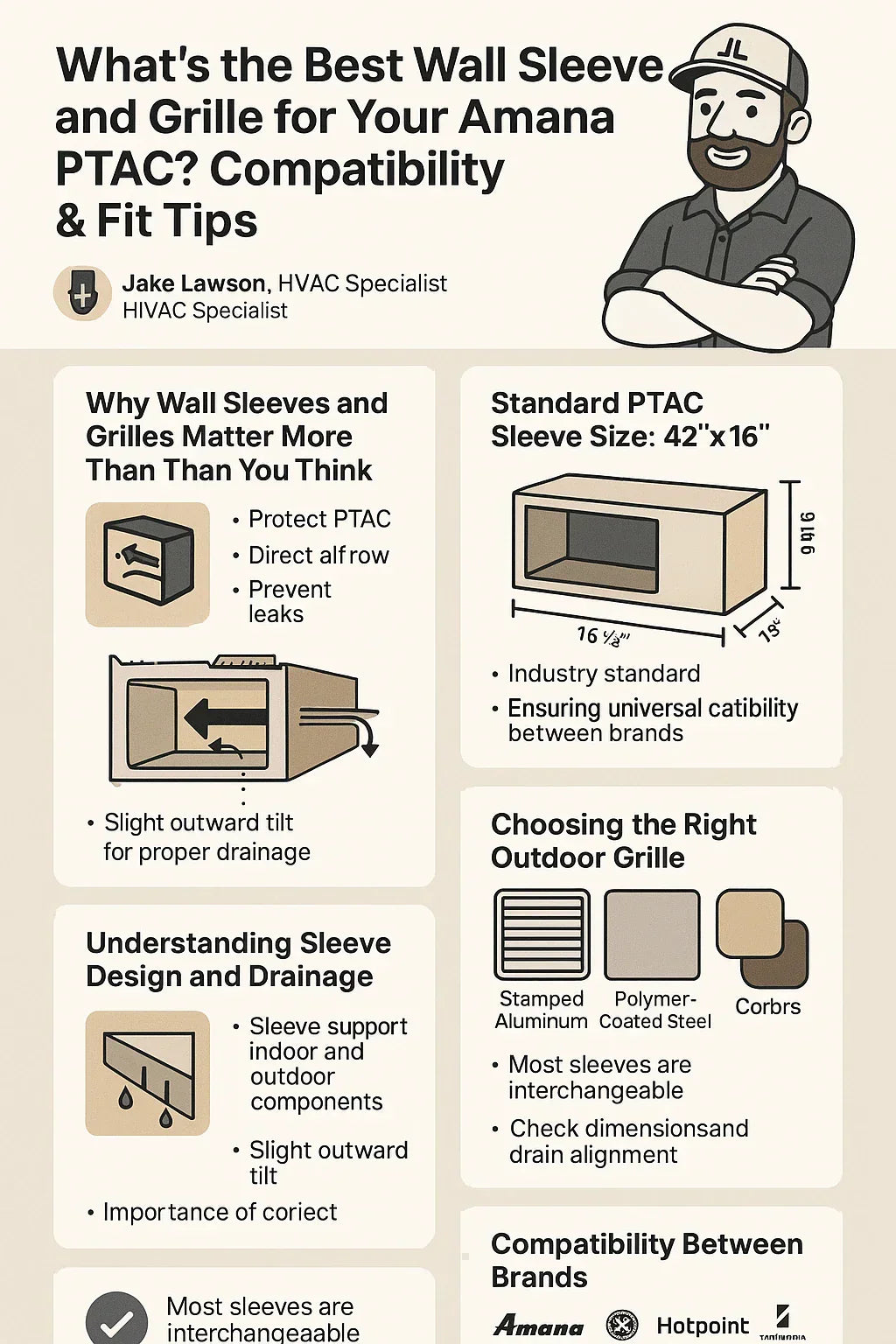

🏁 Why Wall Sleeves and Grilles Matter More Than You Think

When you’re installing a PTAC — that’s a Packaged Terminal Air Conditioner — it’s tempting to think the main star is the unit itself. But if you’ve ever seen a PTAC short out, leak into a drywall cavity, or sound like a jet engine at 2 a.m., nine times out of ten, it wasn’t the unit — it was the wall sleeve or grille.

Those two unsung components make or break the performance, lifespan, and efficiency of your system.

Think of it this way:

-

The sleeve is the foundation — the structural anchor that keeps the PTAC stable, sealed, and draining properly.

-

The grille is the armor — protecting it from rain, debris, and anything the weather throws its way while directing airflow efficiently.

When either one’s wrong — even off by a fraction of an inch — you’ll feel it. Noise goes up. Efficiency goes down. Moisture finds its way in.

So let’s break this down properly. In this guide, I’ll show you how to choose the best wall sleeve and grille for your Amana PTAC, what to look out for, and how to ensure perfect compatibility even if you’re replacing an older GE, Hotpoint, or Friedrich model.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

📏 The Standard PTAC Sleeve Size: 42” x 16”

Here’s the good news: nearly all PTACs in the U.S. share one industry-standard sleeve dimension — 42 inches wide by 16 inches high.

That’s true for Amana, GE Zoneline, Hotpoint, LG, and Friedrich.

That standardization means replacing an old system is a whole lot simpler. You usually don’t need to cut a new wall opening — you just need to verify sleeve depth and drain alignment.

| PTAC Brand | Sleeve Width | Sleeve Height | Depth | Notes |

|---|---|---|---|---|

| Amana | 42” | 16” | 13 ¾”–16” | Universal fit |

| GE Zoneline | 42” | 16” | 16” | Slightly deeper, but compatible |

| Hotpoint | 42” | 16” | 16” | GE-compatible |

| Friedrich | 42” | 16” | 13 ¾” | Shallow design, often needs trim kit |

That said, a few eighths of an inch can make a big difference when it comes to airflow, noise, and sealing.

Jake’s Tip 💬

“Don’t assume all sleeves labeled 42x16 are identical. Check the flange thickness and drain lip before sliding your Amana in — that’s where many retrofits go wrong.”

If your wall sleeve is damaged, rusted, or older than ten years, replace it. Reusing old sleeves may save you $100 today but can cost hundreds later in moisture damage or vibration issues.

🧩 How the Wall Sleeve Works (and Why Fit Is Everything)

A PTAC wall sleeve isn’t just a “box in the wall.” It’s a carefully engineered structure that:

-

Supports the entire chassis weight (60–120 lbs).

-

Channels indoor and outdoor air separately through insulated chambers.

-

Directs condensate drainage outward through small corner ports.

-

Protects wiring and electrical connections from weather exposure.

🧱 Anatomy of a Wall Sleeve

If you looked at one in cross-section, you’d see:

-

Interior flange — sits flush with your interior wall surface.

-

Main cavity — houses the PTAC chassis.

-

Drain lip — slopes outward to let water escape.

-

Exterior flange — anchors to the outdoor grille.

When installed correctly, the sleeve prevents:

-

Condensation backflow into the room.

-

Vibration noise transmission.

-

Air leaks between conditioned and outdoor air paths.

When installed wrong?

It can create water intrusion, “whistling” airflow, and mold behind your wall.

Jake’s Rule 💬

“The sleeve is your PTAC’s foundation — if it’s not square, level, and sloped right, nothing else will perform correctly.”

⚙️ Understanding Sleeve Design and Drainage

Here’s something most homeowners don’t realize: PTAC sleeves should never be perfectly level.

A properly installed sleeve should have about a ¼-inch outward slope (roughly 1 degree).

That’s what allows the condensation your PTAC produces in cooling mode to flow out instead of pooling inside.

🧰 Common Sleeve Design Features:

-

Drain slots at the rear corners.

-

Insulated bottom pan to prevent sweating on humid days.

-

Mounting flanges on both sides for stability.

-

Foam gaskets that prevent air mixing between intake and exhaust zones.

Jake’s Field Tip 💬

“When I inspect a noisy PTAC, 70% of the time it’s not the compressor — it’s the sleeve vibrating because it’s loose or off-level. Tighten those flanges and slope it right.”

For detailed visuals, check out The Furnace Outlet’s Wall Sleeve 101 Guide.

🧱 Amana PTAC Sleeve Options (and Which One You Need)

Amana makes several sleeve options, all designed to fit their Distinctions and standard PTAC models. Let’s go over the main ones you’ll see online or at The Furnace Outlet.

1. Amana WS900B – Universal Steel Sleeve

-

Material: Galvanized steel

-

Depth: 14"

-

Finish: Baked enamel coating

-

Drainage: Dual rear corner drain holes

-

Best for: General applications, hotels, apartments

This is the workhorse — the most common sleeve you’ll find in the field. Fits Amana, GE, and Friedrich models with minor adapter adjustments.

Jake’s Note 💬

“If you’re retrofitting an older GE or Hotpoint, the WS900B is your safest bet. Its flange fits most legacy openings without trimming.”

2. Amana Polymer-Coated Wall Sleeve (Coastal/Corrosive Areas)

-

Material: Polymer-coated galvanized steel

-

Depth: 14"

-

Drainage: Extra corrosion-resistant channels

-

Best for: Humid or coastal regions (Florida, Gulf states)

Salt air is brutal on untreated metal. This sleeve’s coating prevents oxidation and premature rusting.

Jake’s Tip 💬

“If you can smell saltwater from your porch, you need polymer protection. Standard sleeves rust out in two years tops.”

3. Amana Deep Wall Kit (Extended Sleeve)

-

Material: Same as WS900B

-

Depth: 16–20"

-

Includes: Sleeve extender and mounting hardware

-

Best for: Thick masonry or brick walls

Great for older buildings or condos where wall depth exceeds the standard 16".

4. Amana Composite Sleeve

-

Material: Molded polymer composite

-

Depth: 14"

-

Benefits: Lightweight, corrosion-proof, non-conductive

-

Best for: Energy efficiency and quick installs

Jake’s Comment 💬

“Composite sleeves are gaining traction in coastal hotels. They don’t corrode, they’re lighter to handle, and they insulate slightly better.”

🌬 Choosing the Right Outdoor Grille

The grille might look purely cosmetic, but it serves several key functions:

-

Protects the condenser coil from debris and pests.

-

Directs airflow for optimal heat exchange.

-

Prevents rainwater intrusion into the sleeve.

-

Adds structural rigidity to the wall opening.

Grille Types

| Type | Material | Features | Pros | Cons |

|---|---|---|---|---|

| Stamped Aluminum | Lightweight metal | Durable, rust-resistant | Long lifespan | Can rattle if not tightened |

| Polymer-Coated Steel | Painted steel | Corrosion protection | Strong and weatherproof | Slightly heavier |

| Plastic (ABS/Composite) | Molded plastic | Cost-effective | Quiet, no corrosion | Less heat-resistant in sun |

| Louvered Aluminum | Angled fins | Directs airflow downward | Prevents rain intrusion | Pricier |

Color and Finish Choices

Most PTAC grilles come in:

-

Beige (most common for hotels and condos)

-

White (for modern apartments)

-

Dark Bronze or Gray (for commercial exteriors)

Jake’s Tip 💬

“If your wall faces south or west, pick a lighter grille color. It reflects heat better and keeps your condenser cooler.”

For Amana PTACs, the grille’s mounting pattern typically aligns with universal 42x16 sleeves.

Check available options at The Furnace Outlet – PTAC Accessories.

🧩 Cross-Brand Compatibility: Amana, GE, Hotpoint, and Friedrich

Because PTACs share standard dimensions, you can often mix and match sleeves and units. But there are a few details you must check.

✅ Compatible Scenarios

-

Installing an Amana PTAC in an existing GE or Hotpoint sleeve (most work fine).

-

Using an Amana grille with a universal sleeve from Friedrich or LG.

⚠️ Incompatible Scenarios

-

Older GE Zoneline pre-2010 sleeves — drain holes may not align with Amana units.

-

Friedrich PZ and PD series sleeves — use proprietary grille flanges.

-

Amana units in non-standard 40” or 44” wall openings — require filler panels.

Jake’s Field Advice 💬

“Don’t just measure the opening — check the drain lip alignment. That’s where most ‘universal’ claims fail in the real world.”

If you’re upgrading from another brand, Amana offers adapter kits that fill small gaps or redirect drainage alignment.

🧱 Installation Tips: Getting the Perfect Fit

Installing a sleeve and grille the right way makes everything after it easier. Here’s the playbook.

Step 1: Prep the Wall Opening

-

Measure twice — confirm 42” width and 16” height.

-

Locate studs and ensure no plumbing or wiring interference.

-

For new installs, frame a clean opening with treated wood or metal studs.

Step 2: Insert the Sleeve

-

Slide the sleeve in until it’s flush with the indoor wall surface.

-

Tilt outward ¼” for proper drainage.

-

Secure through side flanges into framing.

Step 3: Seal It Up

-

Apply exterior-grade silicone caulk around the sleeve.

-

Add flashing tape or drip edge above for extra moisture protection.

Step 4: Mount the Grille

-

Align screw holes with sleeve flange.

-

Attach grille — do not overtighten (prevents vibration).

-

Confirm louver direction: always angled downward.

Jake’s Pro Tip 💬

“After install, pour half a cup of water into the sleeve’s bottom corner. It should drain out the back within seconds. If not — recheck your slope.”

💧 Weatherproofing and Insulation

A perfectly sized sleeve is only as good as its seal.

Air leaks and moisture infiltration can drastically reduce efficiency and cause long-term wall damage.

Weatherproofing Checklist:

-

Caulk all exterior joints.

-

Add foam insulation tape between sleeve and PTAC chassis.

-

Use flashing above exterior grille to deflect rain.

-

Ensure condensate drains outward — not into your siding.

Jake’s Tip 💬

“If you see moisture around your unit during heavy rain, your seal failed. Re-caulk before it seeps into drywall.”

Learn more about sealing practices from Energy.gov’s Air Sealing Guide.

🧰 Maintenance & Replacement Tips

Once your sleeve and grille are installed, a little seasonal maintenance goes a long way.

Every 3–6 Months

-

Remove grille and clean accumulated debris (leaves, bugs, dirt).

-

Vacuum the drain lip and corner ports.

-

Inspect caulking and reapply if cracking.

Every 1–2 Years

-

Check for rust or corrosion in metal sleeves.

-

Repaint or replace grilles if fading or rust spots appear.

-

Flush the sleeve with water to clear dust and sediment buildup.

Jake’s Quick Fix 💬

“If your PTAC’s blowing louder than usual, check the grille first. Debris or bent fins often block airflow — not the fan motor.”

🧩 Replacement Scenarios: When to Start Fresh

Sometimes, replacing just the PTAC chassis isn’t enough. You may need a new sleeve or grille if you notice:

-

Rust, corrosion, or pitting inside the sleeve.

-

Persistent water accumulation.

-

Peeling paint or rust stains on the wall below the grille.

-

Vibration or rattling from a loose fit.

Replacing the sleeve adds a couple hours to your install, but it’s worth it for peace of mind — and quiet operation.

🏁 Jake’s Recommendations: Best Pairings for Amana PTACs

Here’s my go-to guide when recommending sleeve/grille setups to clients:

| Environment | Sleeve Type | Grille Type | Jake’s Note |

|---|---|---|---|

| Standard Apartments / Hotels | Amana WS900B | Stamped Aluminum | The industry standard combo — simple, durable |

| Coastal Properties | Polymer-Coated Sleeve | ABS Composite Grille | Rust-proof and low-maintenance |

| Older Buildings / Thick Walls | Extended Depth Kit | Steel Louvered Grille | Handles deep masonry installs |

| High-Noise Areas | Composite Sleeve | Aluminum Grille with Sound Baffle | Reduces vibration transmission |

Jake’s Final Tip 💬

“When in doubt, match sleeve and grille to the manufacturer — mixing parts works, but factory pairs always drain and seal best.”

🧾 Jake’s Final Thoughts

Your Amana PTAC is only as good as the sleeve and grille that surround it.

Together, these two components:

-

Keep the system stable and leak-free,

-

Ensure smooth airflow for cooling and heating, and

-

Extend your unit’s lifespan by protecting it from the elements.

If you take away one thing, let it be this:

“A good sleeve and grille aren’t optional add-ons — they’re your PTAC’s first and last line of defense.”

So before you buy that shiny new Amana Distinctions PTAC, make sure you’ve got the right foundation and finishing piece. Because a perfectly sized, well-sealed setup doesn’t just look better — it runs quieter, drains cleaner, and saves energy every single day.

In the next topic we will know more about: Maintenance Guide: Keeping Your Amana PTAC Running Like New