🏢 1. Introduction – Why Troubleshooting Skills Save Time & Money

When a 6–10 ton commercial packaged unit stops doing its job, your building notices—fast.

-

Tenants complain.

-

Utility bills spike.

-

In extreme weather, operations can grind to a halt.

Having basic troubleshooting knowledge:

-

Cuts down on unnecessary service calls.

-

Helps you relay accurate info to HVAC pros.

-

Lets you fix small problems in-house before they snowball.

That said—troubleshooting a large packaged unit is not about guessing. It’s about safe, methodical testing.

⚠ 2. Safety First

Before touching the unit:

-

Lockout/Tagout (LOTO): Shut off and lock power at the disconnect. Attach a tag so no one flips it back on.

-

Wear PPE: Gloves, safety glasses, and in some cases fall protection for rooftop units.

-

Refrigerant Safety: Use gauges rated for the refrigerant type (R-410A, R-454B, etc.). Avoid venting refrigerant—it’s both illegal and dangerous.

-

Gas Safety: For furnace-equipped units, shut off gas at the supply valve before working on combustion components.

Jake’s rule: If you’re not licensed for gas or refrigerant work, limit yourself to inspections and basic fixes.

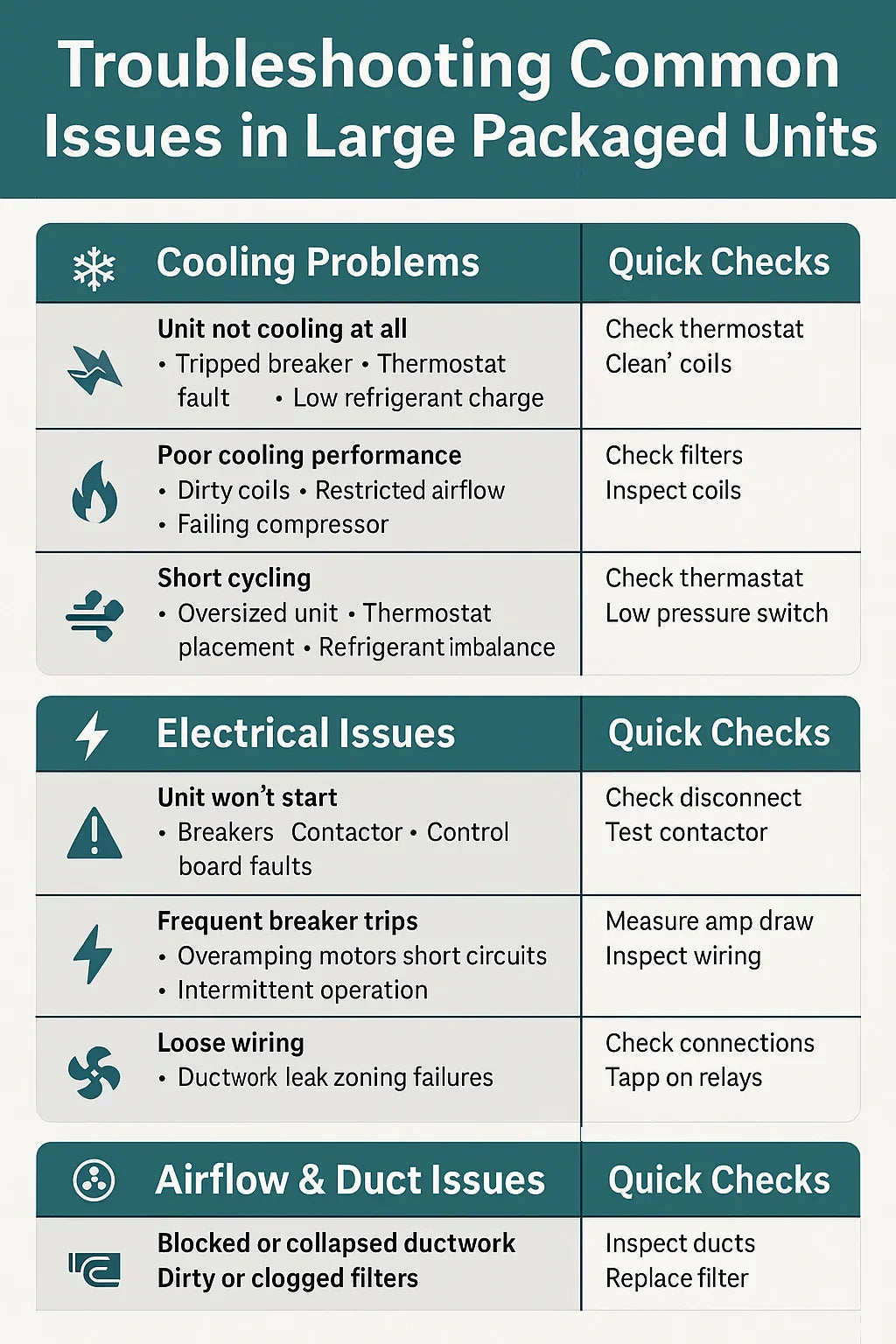

❄ 3. Cooling Problems

A. Unit Not Cooling At All

Likely Causes:

-

Tripped circuit breaker

-

Blown control fuse

-

Thermostat not calling for cooling

-

Contactor not engaging

-

Low-pressure switch open due to refrigerant loss

Steps:

-

Check thermostat mode and setpoint.

-

Inspect breaker/fuses.

-

Listen for contactor pull-in.

-

If contactor is engaged but compressor/fan aren’t running—check capacitor and motor.

B. Poor Cooling Performance

Likely Causes:

-

Dirty condenser coils

-

Clogged air filter

-

Low refrigerant charge

-

Worn compressor

-

Economizer damper stuck open

Steps:

-

Inspect coils for dirt/debris—clean if needed.

-

Replace air filter.

-

Check superheat/subcooling against manufacturer specs.

-

Inspect economizer operation.

C. Short Cycling (Cooling)

Likely Causes:

-

Oversized unit

-

Thermostat placed in poor location

-

Refrigerant imbalance

-

Faulty low-pressure control

Steps:

-

Observe cycle length—should be several minutes, not seconds.

-

Check thermostat placement (avoid drafts/heat sources).

-

Verify refrigerant pressures.

🔥 4. Heating Problems (Gas Furnace Models)

A. No Heat

Likely Causes:

-

Igniter failure

-

No gas supply (closed valve, empty tank)

-

Limit switch open

-

Faulty flame sensor

Steps:

-

Confirm gas valve is open.

-

Reset limit switch if tripped.

-

Test igniter resistance.

-

Clean flame sensor with fine emery cloth.

B. Insufficient Heat

Likely Causes:

-

Dirty burners

-

Low gas pressure

-

Heat exchanger issues

-

Blocked vent

Steps:

-

Inspect burner flame (should be blue, steady).

-

Measure manifold pressure.

-

Check vent/flue for blockages.

C. Uneven Heating

Likely Causes:

-

Duct leaks

-

Zone damper failure

-

Blower belt slipping

Steps:

-

Inspect ducts for damage.

-

Test damper actuator operation.

-

Tighten/replace blower belt.

⚡ 5. Electrical Issues

A. Unit Won’t Start

Likely Causes:

-

Tripped breaker

-

Control transformer failure

-

Thermostat wiring fault

Steps:

-

Reset breaker (if it trips again, investigate short).

-

Measure transformer secondary voltage.

-

Check for 24V signal at contactor.

B. Frequent Breaker Trips

Likely Causes:

-

Overamping fan or compressor motor

-

Short circuit in wiring

-

Bad capacitor causing hard starts

Steps:

-

Measure amp draw on each motor.

-

Inspect wiring insulation.

-

Test capacitors with meter.

C. Intermittent Operation

Likely Causes:

-

Loose wire connections

-

Failing relays

-

Faulty control board

Steps:

-

Tighten all terminal screws.

-

Tap suspect relays—if operation changes, replace.

-

Look for burn marks on board.

🌬 6. Airflow & Duct Issues

Common Symptoms: Low airflow, uneven temperatures, noise in ducts.

Likely Causes:

-

Collapsed or blocked ductwork

-

Dirty filter

-

Blower motor failure

-

Belt misalignment

Steps:

-

Check filter.

-

Measure static pressure.

-

Inspect ducts for obstructions.

-

Verify blower speed setting.

💧 7. Water & Drainage Problems

A. Water Overflow Inside Building

-

Clogged condensate drain line

-

Missing or broken trap

-

Rusted drain pan

Steps:

-

Clear drain line with nitrogen or vacuum pump.

-

Verify trap is installed and functional.

-

Replace damaged pans.

B. Frozen Evaporator Coils

-

Low airflow (dirty filter, blower issue)

-

Low refrigerant charge

Steps:

-

Inspect and correct airflow issues.

-

Check refrigerant pressures.

📑 8. Creating a Troubleshooting Log

Why it matters:

-

Helps track recurring faults.

-

Makes vendor service faster & cheaper.

-

Provides data for capital planning.

Log Template:

-

Date/time

-

Symptom description

-

Steps taken/tests performed

-

Results & readings

-

Resolution or next action

🛠 9. Jake’s Pro Troubleshooting Tips

-

Start Simple: Check the obvious before diving deep.

-

Spare Parts: Keep fuses, belts, and filters in stock.

-

Know Your Unit: Learn the model-specific fault codes.

-

Document Everything: Today’s “minor issue” could be tomorrow’s “big problem” with a history.

-

Seasonal Awareness: Summer issues often tie to cooling, winter to heating—adjust your initial checks accordingly.

In the next topic we will know more about: How Long Do Commercial Packaged AC & Gas Furnace Units Last? Lifespan & Replacement Signs