🏢 1. Introduction – Why a Maintenance Schedule Matters

When you manage a 6–10 ton commercial packaged AC & gas furnace unit, you’re not just running equipment—you’re managing an investment worth tens of thousands of dollars.

Skipping maintenance = higher costs.

-

A clogged coil can raise energy bills by 15–20%.

-

Ignoring burner inspections can lead to unsafe carbon monoxide leaks.

-

Poor refrigerant charge can cut cooling efficiency by 30% or more.

Unlike residential systems, commercial packaged units run longer hours, serve larger spaces, and operate in harsher conditions (especially on rooftops). That means they need a structured, year-round maintenance schedule to:

-

Keep operating costs low

-

Prevent unplanned downtime

-

Extend equipment lifespan

-

Maintain warranty coverage

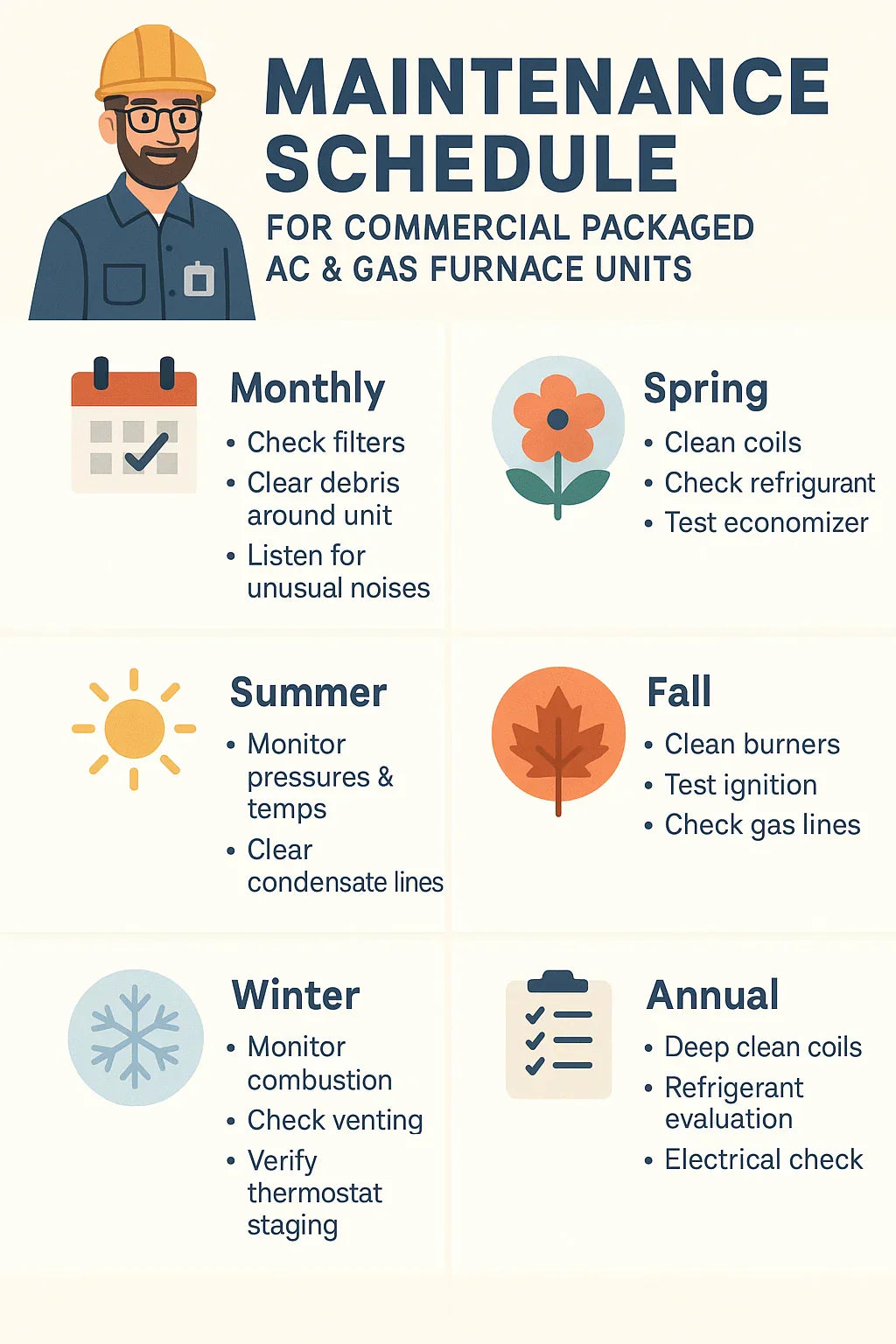

📅 2. Monthly Checks

Even if you have seasonal service contracts, monthly check-ins catch small issues before they become big ones.

Tasks:

-

Inspect Air Filters – Dirty filters restrict airflow, stressing the blower and reducing efficiency. Replace if visibly dirty or after ~30 days in high-use environments.

-

Clear Debris – Remove leaves, trash, or nesting materials around the rooftop unit.

-

Listen for Unusual Sounds – Grinding, squealing, or rattling can signal bearing wear or loose components.

-

Quick Temperature Check – Verify supply air feels cooler (summer) or warmer (winter) than return air.

Jake’s Tip: Keep spare filters on-site—running without one “just until the new ones arrive” is asking for a coil cleaning bill.

🌸 3. Spring – Pre-Cooling Season Prep

Spring is your cooling readiness season. You want everything running at peak efficiency before summer’s high loads.

Tasks:

-

Inspect & Clean Condenser Coils – Use a soft brush or coil cleaner; dirty coils trap heat and reduce cooling output.

-

Check Refrigerant Levels – Low charge = higher energy use and potential compressor damage.

-

Test Economizer Operation – Make sure dampers open/close and sensors are functional; this can save big on mild days.

-

Inspect Belts & Pulleys – Look for cracks or fraying; worn belts can slip and reduce airflow.

-

Verify Thermostat Calibration – Incorrect readings lead to poor comfort control and wasted energy.

Jake’s Tip: Schedule spring service before HVAC contractors get slammed with summer calls—you’ll get faster service and better pricing.

☀ 4. Summer – Peak Cooling Season Maintenance

Once summer hits, your unit is working at full capacity. This is the time to monitor performance closely.

Tasks:

-

Monitor System Pressures & Temps – Check suction/discharge pressures and superheat/subcooling values.

-

Check Condensate Drain Lines – Flush or vacuum lines to prevent water overflow into the building.

-

Inspect Electrical Connections – Look for discoloration, corrosion, or loose terminals caused by heat and vibration.

-

Confirm Airflow Balance – Measure CFM to ensure each zone is getting designed airflow.

Jake’s Tip: Install float switches in condensate pans—cheap insurance against costly water damage.

🍂 5. Fall – Pre-Heating Season Prep

Fall is the time to switch gears and prepare the heating side of your packaged unit.

Tasks:

-

Inspect & Clean Burners – Dust or rust buildup affects flame stability.

-

Test Ignition Systems – Whether spark or hot surface, ensure quick, reliable light-off.

-

Check Gas Line Connections – Use leak-detection fluid or an electronic sniffer.

-

Inspect Heat Exchanger – Look for cracks that could leak combustion gases into the airflow.

-

Lubricate Moving Parts – Blower bearings, damper linkages, and motor shafts.

Jake’s Tip: If your building uses propane, check tank fill level in fall to avoid winter delivery surcharges.

❄ 6. Winter – Peak Heating Season Maintenance

In winter, the heating side of your unit works hard—especially in cold climates.

Tasks:

-

Monitor Gas Pressure & Combustion – Compare readings to manufacturer specs for optimal burn.

-

Inspect Venting – Ensure flue is clear of snow, ice, or debris.

-

Check for Odors – Musty smells may indicate moisture; gas smells = shut down & investigate immediately.

-

Verify Staging – Multi-stage heating should ramp up smoothly without short cycling.

Jake’s Tip: Keep an eye on utility bills—sudden spikes can signal hidden efficiency issues.

🛠 7. Annual Comprehensive Inspection

Once a year, do the deep dive. This is often done during shoulder seasons (spring or fall).

Tasks:

-

Electrical System Check – Inspect contactors, relays, fuses, voltage, and amperage draws.

-

Deep Coil Cleaning – Both evaporator and condenser.

-

Refrigerant System Evaluation – Check for leaks, oil stains, and proper charge.

-

Review Maintenance Logs – Look for patterns in breakdowns or parts replacements.

-

Update Service Tags – Record all work done for warranty and compliance.

Jake’s Tip: Use the AHRI Performance Check to ensure your unit is still meeting rated EER/IEER values.

📑 8. Maintenance Log & Compliance

Keeping records isn’t just for your peace of mind—it’s often required.

-

Warranty Requirements: Many manufacturers require documented maintenance to honor claims.

-

Insurance Compliance: Some policies need proof of regular inspections.

-

OSHA & Local Code: Access ladders, tie-off points, and guardrails may be inspected during service.

Jake’s Tip: Digital logs make it easier to track service history and share with vendors.

📝 9. Jake’s Pro Tips for Long-Term Reliability

-

Change Filters on Time – Don’t stretch beyond recommended intervals.

-

Book Pre-Season Maintenance Early – Avoid emergency calls at premium rates.

-

Train In-House Staff – For basic visual checks and filter changes.

-

Use Quality Replacement Parts – Cheap components often fail sooner.

-

Don’t Ignore Small Problems – Unusual sounds, smells, or vibrations almost always mean trouble ahead.

✅ 10. Sample Seasonal Maintenance Schedule

| Month/Season | Cooling Tasks | Heating Tasks | Shared Tasks |

|---|---|---|---|

| Monthly | Check filters, clear debris | — | Listen for unusual noises |

| Spring | Clean coils, check refrigerant, test economizer | — | Inspect belts, calibrate thermostat |

| Summer | Monitor pressures/temps, clear condensate lines | — | Inspect electrical |

| Fall | — | Clean burners, test ignition, check gas lines | Inspect heat exchanger |

| Winter | — | Monitor combustion, check venting | Verify thermostat staging |

| Annual | Deep coil clean, refrigerant evaluation | Burner inspection | Electrical check, log review |