(Jake’s no-nonsense guide to knowing when it’s time to stop fixing and start planning)

🏢 1. Introduction – Why Knowing Your Unit’s Lifespan Matters

If you manage a building, you already know: HVAC isn’t just a comfort system—it’s infrastructure.

When a 6–10 ton commercial packaged AC & gas furnace unit goes down unexpectedly:

-

Business operations suffer.

-

Repair costs stack up fast.

-

The scramble to find a crane slot and a new unit in peak season is miserable.

Knowing your unit’s lifespan is about control—control over your budget, your comfort, and your schedule. By tracking performance and watching for end-of-life signs, you can:

-

Schedule replacements in mild seasons (spring/fall) to avoid heat waves or cold snaps.

-

Take advantage of utility rebates and tax credits.

-

Bundle other roof work (like membrane repair) with the HVAC change-out.

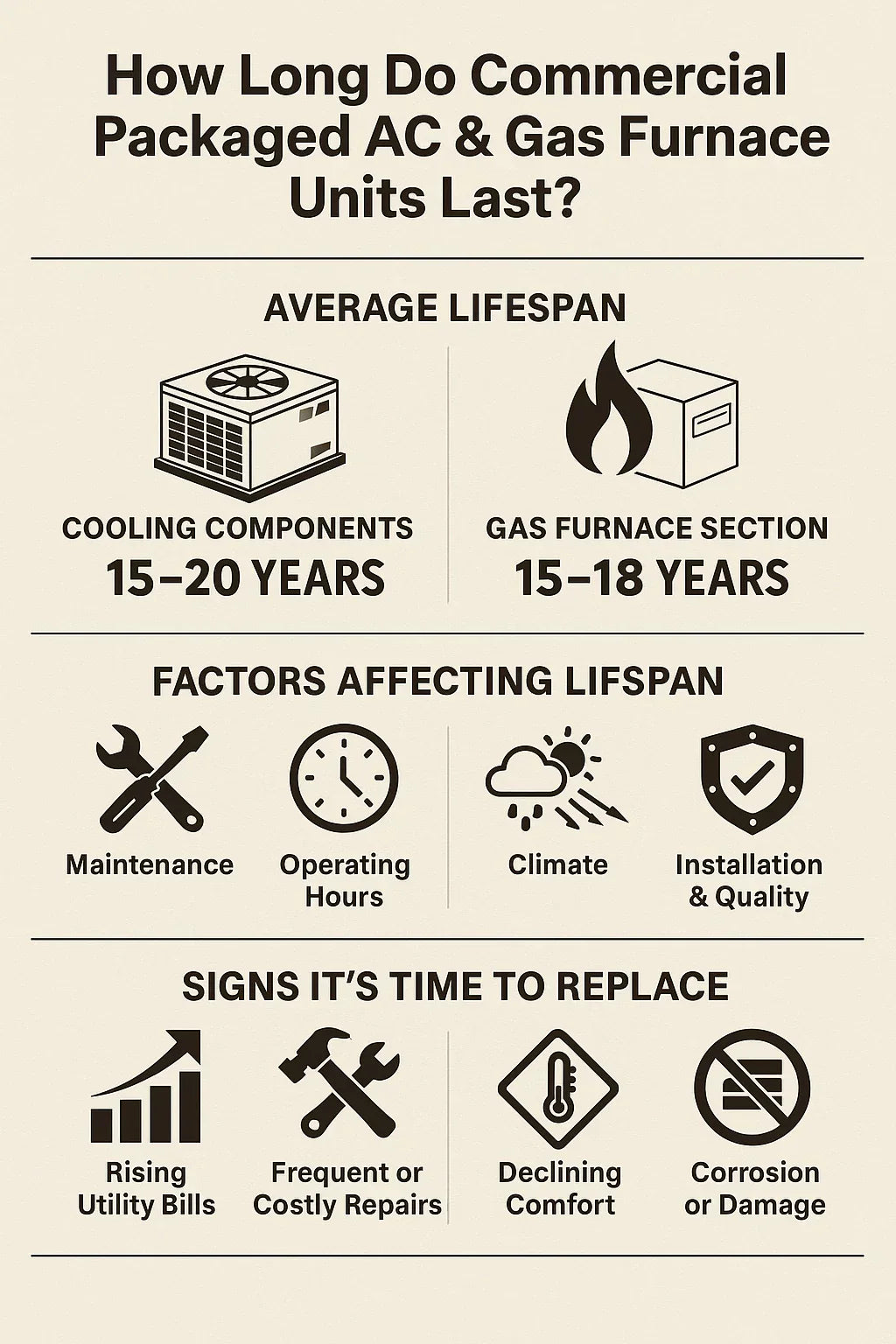

📆 2. Average Lifespan of Commercial Packaged Units

Industry Norms

-

Cooling Components (compressor, coils, blower): 15–20 years with proper care

-

Gas Furnace Section (burners, heat exchanger): 15–18 years

-

Economizers & Controls: Often require replacement sooner, around 8–12 years

Location Matters

-

Rooftop Units (RTUs): More exposure to weather extremes, wind-driven debris, and thermal cycling = shorter life if maintenance lapses.

-

Ground-Level Units: Easier to access and maintain, but vulnerable to vandalism and landscaping damage.

Climate Impacts

-

Hot/Dry Climates: Heat stress shortens compressor life.

-

Humid/Coastal Areas: Salt corrosion can eat coils in under 10 years without protective coatings.

-

Cold Regions: Freeze-thaw cycles can crack heat exchangers faster.

⚙ 3. Factors That Influence Lifespan

1. Maintenance Quality & Frequency

-

Dirty coils = high head pressures = compressor strain.

-

Skipped filter changes = blower motor overheating.

-

Incomplete seasonal inspections = small issues become big failures.

2. Operating Hours & Load Profile

-

Units running 24/7 (like data centers) wear out far faster than those running only during business hours.

-

Short cycling from oversizing accelerates mechanical wear.

3. Environmental Exposure

-

Rooftop grease exhaust from restaurants coats coils.

-

Pollen and cottonwood clog fins seasonally.

-

Pollution can corrode metal parts.

4. Installation Quality

-

Poor duct sealing leads to airflow imbalance, shortening fan and heat exchanger life.

-

Improper leveling can cause oil return issues in compressors.

5. Brand and Build Quality

-

Heavy-gauge cabinets, coated coils, and premium components often last longer—but only if maintained.

🛠 4. Signs Your Unit Is Nearing the End

Rising Utility Bills

If your energy use spikes but your occupancy hasn’t changed, efficiency is dropping—likely from worn compressors, fouled coils, or leaky ducts.

Frequent or Costly Repairs

If you’re replacing major components every season, it’s time to compare costs. That $2,000 repair might be 20% of a new unit.

Declining Comfort

Uneven heating/cooling, weak airflow, or persistent humidity problems can indicate internal wear.

Unusual Noises or Vibrations

Grinding, banging, or metal-on-metal sounds often mean motor or bearing failure is close.

Visible Corrosion or Coil Damage

Severe fin deterioration or rusted-through panels indicate the system has been weather-beaten beyond economical repair.

💰 5. Repair vs. Replace: The 50% Rule

The 50% Rule says: If a repair costs more than 50% of replacement, and the unit is past 75% of its expected life, replace it.

Example:

-

New 10-ton packaged unit installed cost: $20,000

-

Proposed compressor replacement: $10,500

-

Unit age: 16 years

→ Replace, don’t repair.

Other considerations:

-

Energy Savings: Newer models can be 15–30% more efficient, with EER and IEER gains.

-

Rebates: Many utilities offer incentives for high-efficiency rooftop units.

-

Tax Deductions: Section 179 in the U.S. may allow accelerated depreciation.

🔍 6. Jake’s Inspection Checklist for End-of-Life Units

Cooling Side:

-

Compressor amp draw within manufacturer range?

-

Condenser coil fins intact and clean?

-

Blower wheel balanced and clean?

Heating Side:

-

Heat exchanger crack-free and not warped?

-

Burner flame steady and blue?

-

Ignition system reliable?

General:

-

Cabinet rust or corrosion?

-

Electrical contactors pitted or burnt?

-

Duct connections tight?

-

Economizer dampers moving freely?

📑 7. Planning for Replacement

Lead Times

Post-2020, large HVAC units can have lead times of 8–20 weeks, depending on supply chain conditions. Don’t wait until failure.

Budgeting

Include:

-

Equipment cost

-

Crane rental

-

Curb adapter fabrication

-

Electrical/gas line modifications

-

Controls integration

Timing the Change-Out

Spring and fall are ideal—mild weather means you won’t stress tenants, and contractors are less booked.

📝 8. Jake’s Pro Tips

-

Start planning at year 12—get a capital budget line item ready.

-

Track energy trends—rising kWh or therm usage is often the first sign.

-

Bundle work—if replacing the unit, consider roof membrane repairs, duct sealing, or curb upgrades at the same time.

-

Don’t ignore control upgrades—a new unit with old, inefficient controls won’t deliver full savings.

-

Keep records—service logs help prove the need for replacement to upper management.

In the next topic we will know more about: Do 6–10 Ton Commercial Packaged Units Qualify for Energy Rebates or Tax Credits?