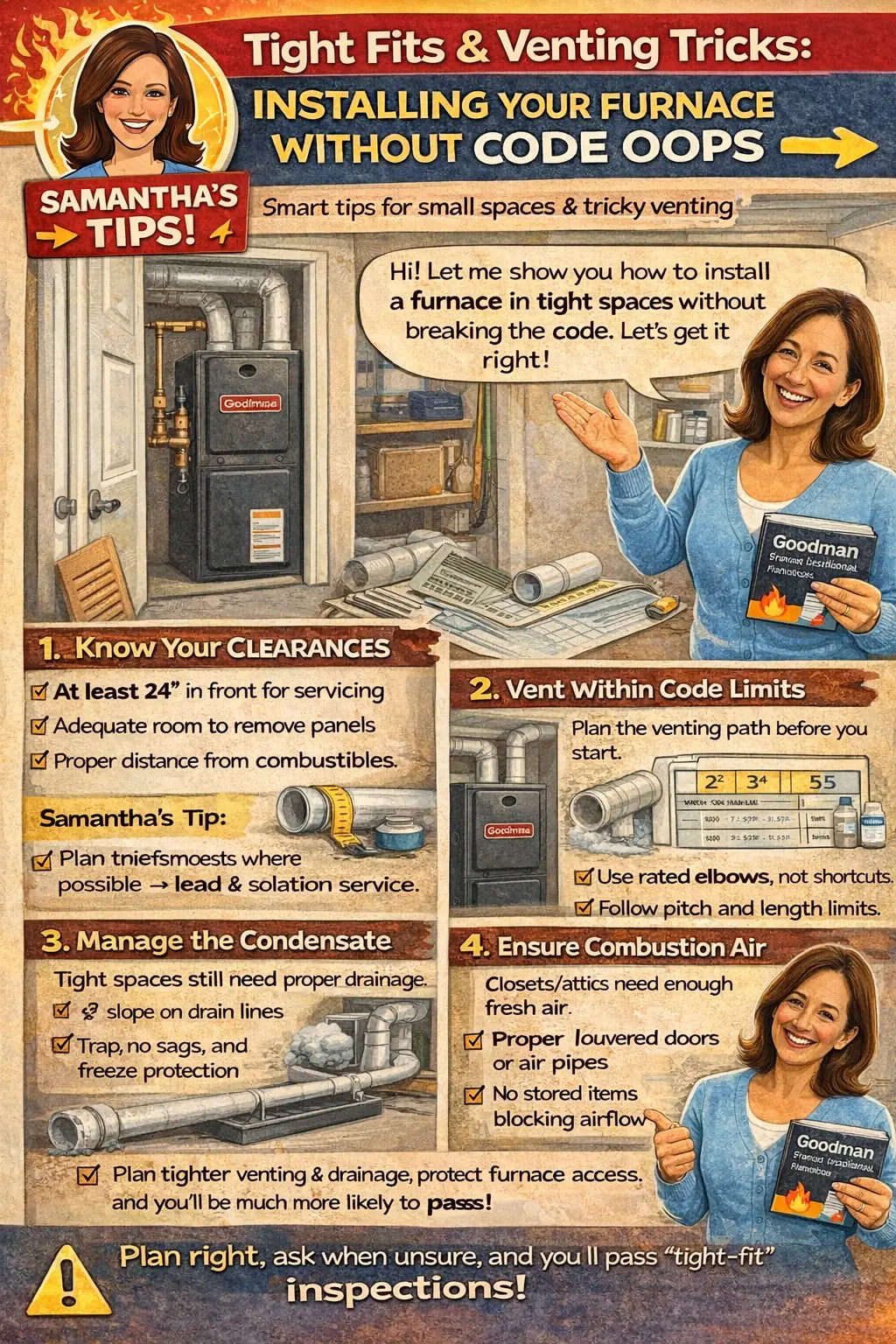

— Samantha’s Real-World Guide to Small Spaces, Smart Venting, and Passing Inspection the First Time

If you’ve ever tried to install (or replace) a gas furnace in a closet, attic, crawl space, or tight utility room, you already know the truth:

👉 Most installation problems aren’t about the furnace—they’re about the space.

High-efficiency furnaces like Goodman’s 90%+ AFUE models are incredibly capable, but they are also less forgiving. Tight clearances, complex vent runs, and condensate routing all have to be right—or you’ll end up with failed inspections, nuisance shutdowns, or safety hazards that don’t show up until winter.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

This guide is my Samantha-style playbook for navigating tight fits and tricky venting without violating code, voiding warranties, or creating future service nightmares.

🧠 Why Tight Installations Are Where Most Code Mistakes Happen

When space is limited, installers (and DIYers) are tempted to:

-

“Borrow” clearance space

-

Shorten vent runs creatively

-

Ignore service access requirements

-

Assume inspectors won’t notice hidden issues

Unfortunately, inspectors always notice—and manufacturers do too when warranty claims come up.

The key mindset shift:

Code compliance isn’t about fitting the furnace in. It’s about fitting the furnace in safely and serviceably.

📏🚪 Step 1: Understand the Three Clearances That Matter (Not Just One)

Most people think clearance = distance from combustibles. That’s only part of the story.

The three clearance types

-

Clearance to combustibles (fire safety)

-

Service clearance (panels must be removable)

-

Airflow clearance (return air & combustion air)

Goodman installation manuals list minimum clearances, but those are minimums, not comfort targets.

Goodman installation manual (example):

https://hvacdirect.com/media/pdf/GR9T96-GD9T96-Install-Manual.pdf

👉 Samantha tip:

If a tech can’t remove the blower or access the control board without contortions, the install will fail eventually—even if it passes inspection today.

🧱🛠️ Tight Closets: How to Install Without Blocking Service Panels

Closet installs are common—and commonly done wrong.

Common closet mistakes

-

Furnace shoved against one wall

-

Door opening blocks panel removal

-

Return air pulled from the same closet (often prohibited)

-

Combustion air ignored

Smart closet strategies

-

Center the furnace where possible

-

Use louvered doors or dedicated return paths (per code and manual)

-

Verify door swing doesn’t block service panels

-

Confirm combustion air requirements are met

👉 Samantha tip:

A closet furnace must be breathable, serviceable, and inspectable—not just hidden.

🌬️📐 Step 2: Venting in Tight Spaces—Why Planning Beats Creativity

High-efficiency furnaces rely on precise venting geometry.

Why venting gets tricky in small spaces

-

Limited wall penetration options

-

Short vertical rise

-

Multiple elbows in tight runs

-

Condensate pooling risk

Venting rules you can’t bend

-

Maximum equivalent vent length

-

Elbow penalties (each elbow reduces allowable length)

-

Approved pipe materials only

-

Proper pitch back to the furnace

These rules are laid out in the venting tables—not suggestions.

👉 Samantha tip:

If your vent plan requires “figuring it out as you go,” stop and redraw it first.

❄️💧 Step 3: Condensate Drainage in Confined Areas (The Silent Failure Point)

Condensate is one of the most overlooked hazards in tight installations.

What goes wrong

-

Drain lines sag behind units

-

Horizontal runs lack slope

-

Freezing occurs in unconditioned spaces

-

No secondary protection in attics

High-efficiency furnaces can shut down repeatedly if condensate backs up—and that often happens only during long cold cycles.

ENERGY STAR commissioning guidance emphasizes proper drainage as part of system safety.

https://www.energystar.gov/sites/default/files/2025-01/National%20HVAC%20Commissioning%20Checklist_Rev%2014.pdf

👉 Samantha tip:

If condensate can’t drain by gravity and design, it will eventually drain by accident—usually onto your ceiling.

🔥🏠 Step 4: Combustion Air in Small Mechanical Spaces

Gas furnaces need oxygen to burn safely. Tight spaces make that tricky.

Common combustion air mistakes

-

Relying on leaky construction (no longer valid)

-

Blocking intake openings with storage

-

Assuming “it worked before” still applies

Goodman manuals specify combustion air requirements that align with national fuel gas safety standards like NFPA 54.

👉 Samantha tip:

If you wouldn’t feel comfortable breathing in that space all winter, your furnace probably won’t either.

🔄⬆️↔️ Step 5: Orientation Tricks for Tight Fits (Upflow vs Horizontal)

Choosing the right orientation can solve space problems before they start.

When horizontal helps

-

Attics with limited height

-

Crawl spaces

-

Ductwork that runs laterally

When upflow is safer

-

Basements

-

Utility rooms

-

Spaces where condensate drainage matters

Multi-position furnaces give flexibility—but only if installed exactly per the manual.

👉 Samantha tip:

Orientation should follow ductwork and drainage, not just what “fits.”

🔊📉 Step 6: Noise & Vibration in Confined Installs

Tight spaces amplify sound.

Common noise issues

-

Rigid duct connections

-

Units touching framing

-

Poorly supported vent pipes

-

Return air turbulence

Noise isn’t just annoying—it’s often a sign of airflow stress or vibration that can shorten component life.

👉 Samantha tip:

If it sounds loud now, it’ll sound worse at 2 a.m. in January.

🧾🛑 Step 7: Passing Inspection Without Rework

Inspectors typically check:

-

Clearances

-

Venting materials, slope, and termination

-

Combustion air

-

Gas piping and shutoffs

-

Condensate management

-

Service access

Skipping permits or inspections may save time—but it shifts all liability to you.

👉 Samantha tip:

The easiest inspection is the one you design for from day one.

🧠 Samantha’s “No-Oops” Tight-Space Checklist

Before you install, ask yourself:

-

✅ Can all panels be removed easily?

-

✅ Is venting within table limits?

-

✅ Does condensate drain by design—not luck?

-

✅ Is combustion air clearly defined?

-

✅ Would a technician thank you later?

If the answer is “maybe,” revise before installing.

🧠 Final Samantha Take: Tight Spaces Demand Better Planning—Not Shortcuts

Installing a furnace in a tight space isn’t about squeezing harder—it’s about thinking smarter.

When you:

-

Respect clearances

-

Follow vent tables

-

Plan drainage deliberately

-

Protect service access

…you avoid the most common code oops that lead to failed inspections, callbacks, and unsafe operation.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Wiring & Controls for Newbies: Connecting Your Goodman Furnace Safely