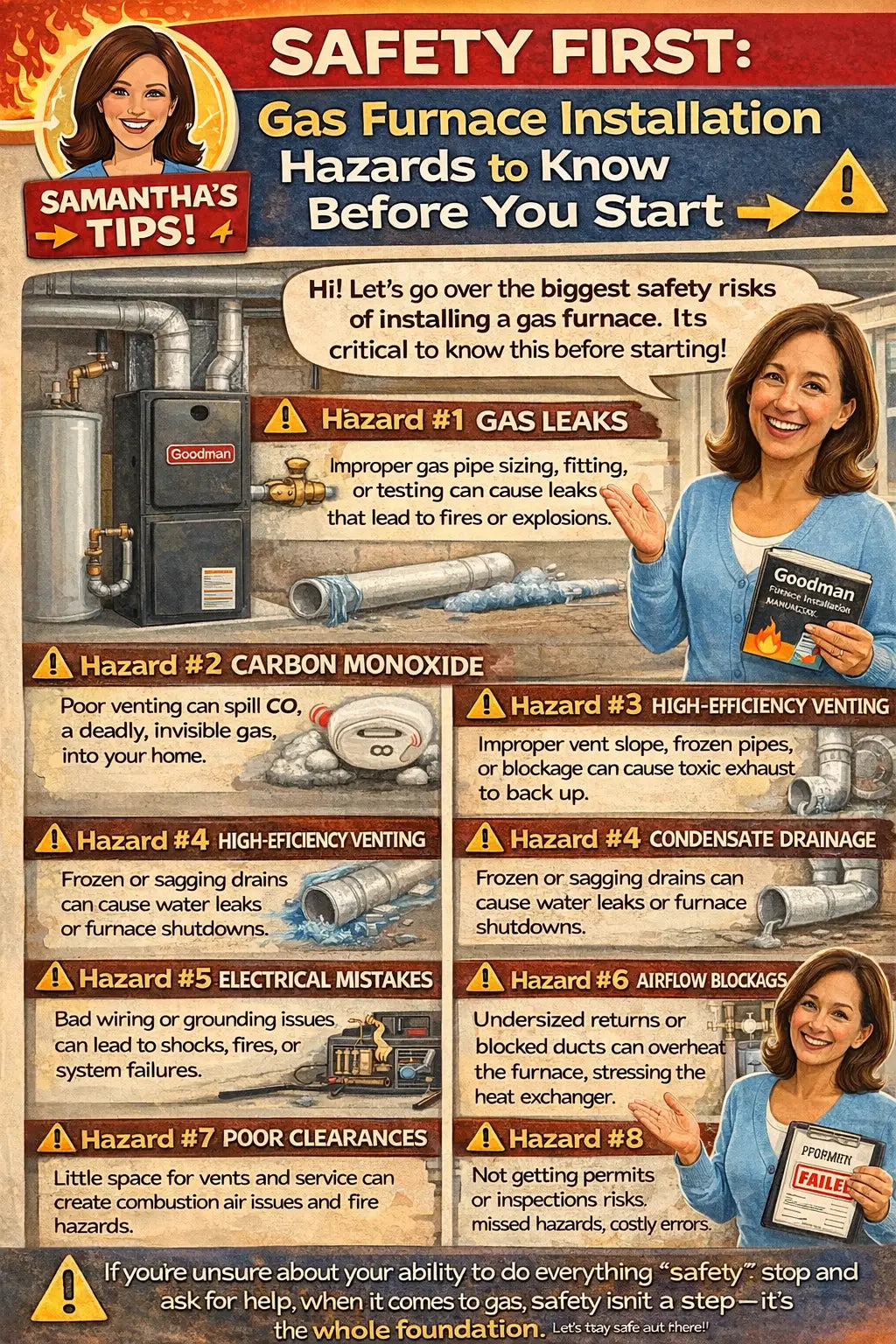

— Samantha’s No-Nonsense Guide to Avoiding the Mistakes That Put Homes (and People) at Risk

Installing a gas furnace is not just another home project. Unlike paint, flooring, or cabinetry, a furnace combines natural gas, electricity, combustion air, venting, and heat—all in one box. When something goes wrong, the risks aren’t cosmetic. They’re serious.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

I’ve learned this lesson the hard way: most furnace problems don’t start after installation—they start during installation. This guide is designed to help you understand the real hazards involved before you begin, so you can decide what’s safe to handle yourself, what requires extra planning, and when it’s time to bring in a professional.

🧠 Why Furnace Safety Starts Before the First Tool Comes Out

Gas furnace hazards usually fall into one of two categories:

-

Immediate dangers (gas leaks, carbon monoxide exposure, electrical shock)

-

Delayed dangers (failed venting, moisture damage, heat exchanger stress)

The scariest part?

Many delayed hazards don’t show up until weeks or months later, often during the coldest nights of the year.

That’s why every manufacturer—including Goodman—builds safety instructions directly into their installation manuals, and why inspectors treat those instructions as law.

🔥⛽ Hazard #1: Gas Leaks & Improper Gas Piping

Why this is dangerous

Natural gas is highly combustible. Even small leaks can:

-

Create fire or explosion risk

-

Cause delayed ignition

-

Damage gas valves and burners over time

Common installation mistakes

-

Incorrect pipe sizing

-

Missing or improperly installed sediment (drip) traps

-

Over-tightened or under-tightened fittings

-

Skipping pressure testing

What the manual expects

Goodman installation manuals specify:

-

Approved gas pressure ranges

-

Proper pipe sizing guidance

-

Leak-testing requirements

-

Shutoff valve placement

These requirements align with national fuel gas safety standards such as NFPA 54 (National Fuel Gas Code), which many local codes adopt.

👉 Samantha tip:

If you don’t own a manometer—or don’t know how to use one—you’re already past the “DIY-safe” line for gas work.

☠️🫁 Hazard #2: Carbon Monoxide (CO) Exposure

Why this is dangerous

Carbon monoxide is:

-

Colorless

-

Odorless

-

Potentially deadly

Improper installation can allow combustion gases to spill back into living spaces instead of venting outdoors.

Installation causes of CO risk

-

Incorrect vent sizing

-

Poor vent slope

-

Blocked or frozen vent terminations

-

Inadequate combustion air

-

Loose or leaking vent joints

The CDC consistently warns that fuel-burning appliances are a leading source of CO exposure in homes.

🔗 https://www.cdc.gov/carbon-monoxide/factsheets/furnace-safety-fact-sheet.html

👉 Samantha tip:

CO alarms are not optional backups—they are last lines of defense. Proper venting is the real protection.

🌬️🚫 Hazard #3: Improper Venting of High-Efficiency Furnaces

Modern 90%+ AFUE furnaces (like Goodman 96% models) are Category IV condensing appliances. That changes everything about venting.

Why high-efficiency venting is risky if done wrong

-

Exhaust gases are cooler → more condensation

-

Condensate can freeze, back up, or corrode components

-

Pressure-sensitive safety switches will shut the system down

Common venting mistakes

-

Ignoring vent length and elbow limits

-

Using incorrect pipe materials

-

Poor termination placement (too close to windows, grade, or snow lines)

-

Failing to support vent piping properly

Goodman’s installation manuals include vent tables that define what is allowed—and what is not.

🔗 https://hvacdirect.com/media/pdf/GR9T96-GD9T96-Install-Manual.pdf

👉 Samantha tip:

If venting is “figured out as you go,” it’s already unsafe.

💧❄️ Hazard #4: Condensate Drainage Failures

High-efficiency furnaces produce water—sometimes gallons per day during heavy operation.

Why this matters

If condensate can’t drain properly:

-

Pressure switches trip

-

Furnaces lock out

-

Water leaks damage ceilings, floors, and heat exchangers

Common drainage hazards

-

Insufficient pipe slope

-

Sagging drain lines

-

Freezing in unconditioned spaces

-

No secondary drain protection in attics

Goodman manuals clearly outline condensate handling requirements, but many installers underestimate how critical this system is.

👉 Samantha tip:

Condensate problems don’t look dangerous—until the furnace shuts off on the coldest night of the year.

⚡⚠️ Hazard #5: Electrical & Control Wiring Mistakes

Gas furnaces may burn fuel—but they run on electricity.

Electrical risks include

-

Shock hazards

-

Control board damage

-

False safety lockouts

-

Blower motor failure

Common wiring mistakes

-

Incorrect grounding

-

Miswired thermostat staging

-

Loose low-voltage connections

-

Sharing circuits improperly

Manufacturers expect installations to follow electrical safety standards and their wiring diagrams exactly.

👉 Samantha tip:

If you don’t understand the wiring diagram, don’t “match colors and hope.”

🔥🌡️ Hazard #6: Airflow & Overheating Risks

A furnace relies on proper airflow to:

-

Cool the heat exchanger

-

Prevent limit switch trips

-

Deliver even comfort

What goes wrong

-

Undersized return air

-

Improper blower settings

-

Blocked or restrictive ductwork

Overheating stresses the heat exchanger, which can eventually crack—one of the most serious (and expensive) furnace failures.

ENERGY STAR commissioning guidelines emphasize airflow verification for safety and performance.

🔗 https://www.energystar.gov/sites/default/files/2025-01/National%20HVAC%20Commissioning%20Checklist_Rev%2014.pdf

👉 Samantha tip:

A furnace that short-cycles or smells “hot” is sending a warning—listen to it.

🏠🚪 Hazard #7: Poor Clearances & Combustion Air

Why this matters

Gas furnaces need:

-

Space to breathe

-

Space to stay cool

-

Space to be serviced safely

Common clearance mistakes

-

Installing too close to walls or framing

-

Blocking service panels

-

Inadequate combustion air in closets or sealed spaces

Goodman manuals clearly list minimum clearances to combustibles and service access requirements.

👉 Samantha tip:

If a technician has to remove drywall to service the furnace later, the install wasn’t done safely.

🧾🛑 Hazard #8: Skipping Permits, Inspections & Commissioning

This isn’t just red tape—it’s a safety net.

Why inspections matter

-

Catch gas leaks and venting errors

-

Verify clearances and airflow

-

Protect homeowners and future occupants

Commissioning ensures:

-

Safety controls function properly

-

Gas pressure is correct

-

Airflow and temperature rise are within limits

Skipping this step puts all risk on you.

🧠 Final Samantha Take: Safety Isn’t a Feature—It’s the Foundation

Gas furnace installation hazards aren’t rare—they’re predictable. And almost all of them trace back to rushed installs, skipped steps, or misunderstood manuals.

If you take one thing from this guide, let it be this:

If you can’t explain how your furnace handles gas, air, exhaust, water, and electricity safely—pause before you proceed.

Doing it right isn’t about fear. It’s about respect—for the system, your home, and the people living in it.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Tight Fits & Venting Tricks: Installing Your Furnace Without Code Oops