Most techs listen for one thing at startup:

“Is it loud?”

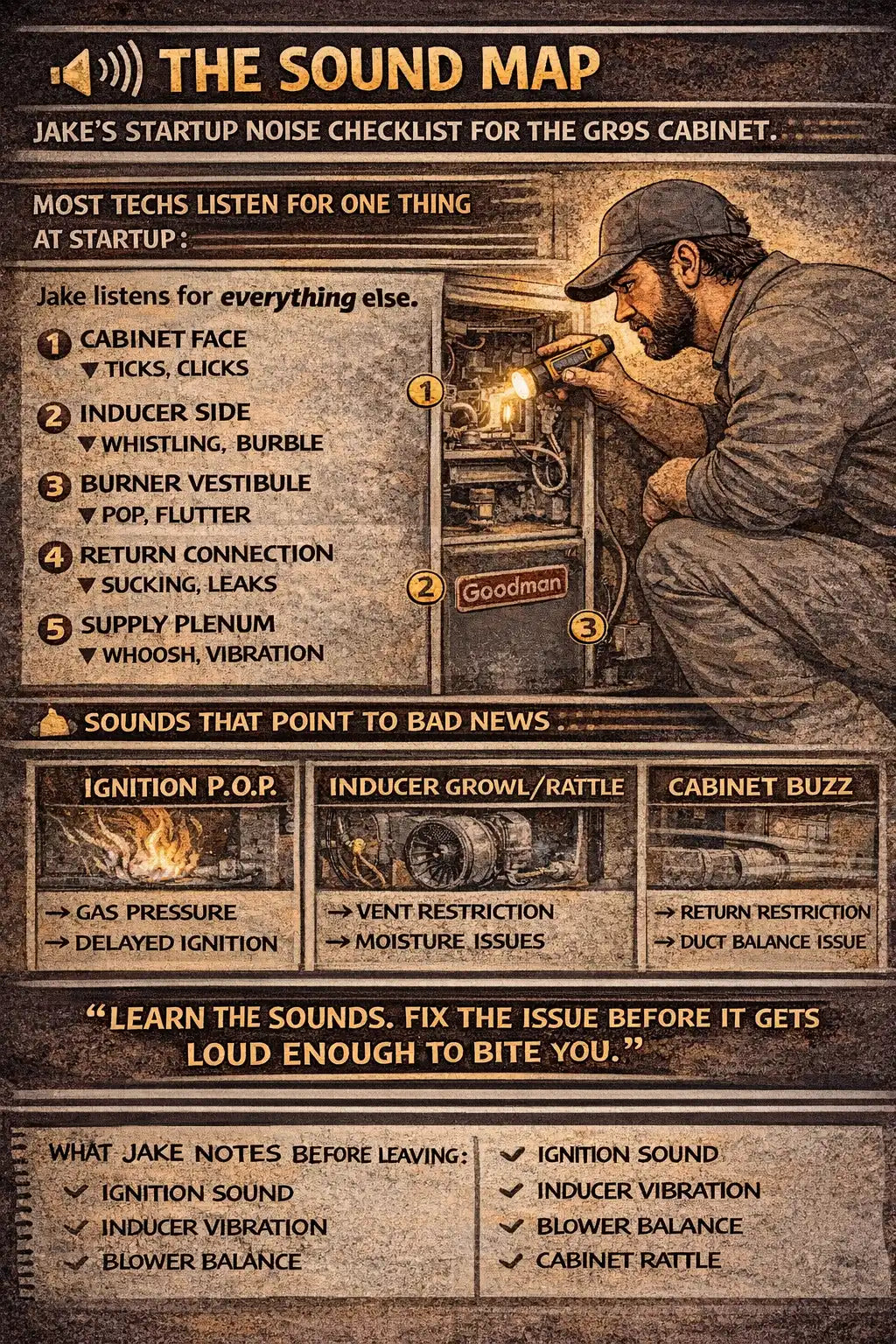

Jake listens for everything else.

Because furnaces don’t just make noise — they tell stories. And the first startup is when those stories are clearest, before heat soak, before airflow smooths out turbulence, and before homeowners learn to ignore sounds they shouldn’t.

On the Goodman GR9S800803BN, startup noise is especially honest. The cabinet design doesn’t hide much. If something’s wrong, it usually says so — quietly at first.

This article breaks down Jake’s startup sound map: what he listens for, where he stands, and how specific sounds predict airflow problems, electrical issues, gas pressure drift, and future callbacks long before a fault code ever appears.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🧠 Why Startup Noise Is Better Data Than Fault Codes

Fault codes are reactive.

Noise is predictive.

At startup:

-

Metal is cold

-

Airflow is unbalanced

-

Pressure hasn’t stabilized

-

Components haven’t masked vibration yet

That’s when:

-

Loose panels speak up

-

Duct restrictions whistle

-

Gas valves announce pressure issues

-

Blowers reveal imbalance

“If it’s going to complain later, it whispers first.”

Jake listens for whispers.

🧭 Jake’s Sound Map Philosophy: Location Matters

Jake doesn’t stand in one spot.

He moves.

Because where a sound is heard matters as much as what it sounds like.

His listening zones:

-

Cabinet face

-

Inducer side

-

Burner vestibule

-

Return duct connection

-

Supply plenum

-

Adjacent framing

Each zone tells a different story.

🔥 Ignition Sounds: The First Clue

What Jake expects:

-

A clean click

-

A smooth light-off

-

No hesitation

-

No sharp “bang”

Red flags at ignition:

-

Pop or thump → delayed ignition, gas pressure issues

-

Metal tick → burner expansion stress

-

Flutter → unstable flame or draft

Ignition noise problems often trace back to:

-

Gas pressure drift

-

Igniter positioning

-

Burner alignment

Jake listens closely here because ignition noise rarely fixes itself.

🌪️ Inducer Sounds: Draft Talking Back

The inducer is the furnace’s throat.

Healthy inducer sound:

-

Smooth ramp-up

-

Steady pitch

-

No pulsing or growl

Sounds Jake flags immediately:

-

Growling → vent restriction or backpressure

-

Surging → draft instability

-

Rattle → mounting or wheel imbalance

-

Moist hiss → condensate where it shouldn’t be

Inducer noise often pairs with venting and moisture issues described in NFPA venting guidance

(NFPA 54 – National Fuel Gas Code).

🧱 Cabinet Sounds: The Box Doesn’t Lie

The GR9S cabinet is honest — sometimes brutally so.

Jake taps lightly and listens during startup for:

-

Panel buzz

-

Seam vibration

-

Door resonance

What cabinet noise usually means:

-

High static pressure

-

Return-side restriction

-

Poor sealing

-

Excessive negative pressure

A quiet cabinet at startup usually stays quiet.

A noisy one rarely improves with time.

🌬️ Blower Pre-Noise: What Happens Before Full Speed

Even before the blower ramps fully, Jake listens for:

-

Air rushing prematurely

-

Whistling at seams

-

Return rumble

These early sounds often indicate:

-

Undersized returns

-

Filter choke points

-

Poor transitions

By the time the blower is at full speed, these noises may fade — but the problem remains.

This aligns with ACCA airflow diagnostics that warn against relying solely on full-speed observations

(ACCA Manual D Overview).

🔊 Blower Ramp-Up: Where Airflow Confesses

When the blower ramps:

-

Restrictions announce themselves

-

Ducts speak

-

Registers react

Sounds Jake decodes:

-

Whistle → high static, sharp transitions

-

Low rumble → return restriction or leaks

-

Vibration → blower imbalance or cabinet flex

Jake doesn’t adjust blower delay to hide this.

He shortens delay to expose it.

🧰 Supply Plenum & Duct Sounds: Echoes of Design

Jake places a hand on the plenum during startup.

Not to feel heat — to feel vibration.

Supply-side noise often points to:

-

Sudden transitions

-

Poorly sized plenums

-

Flex duct tension

-

Sharp turns too close to the cabinet

Noise here is rarely a furnace problem.

It’s a system problem.

🧲 Electrical Noise: Clicks, Chatter, and Trouble

Jake listens for:

-

Relay chatter

-

Repeated clicking

-

Buzzing near the board

These often indicate:

-

Low voltage under load

-

Poor grounding

-

Loose connections

Electrical noise at startup is a major predictor of future lockouts, as outlined in HVAC electrical diagnostics

(HVAC School – Electrical Noise & Voltage).

🎧 Jake’s Rule: If It Changes After 10 Minutes, It Still Counts

A common mistake:

“It quieted down after a bit.”

Jake doesn’t care.

If a sound appears:

-

At cold start

-

During ignition

-

During ramp-up

…it matters — even if it disappears later.

Heat soak hides problems.

Noise before heat reveals them.

📝 Jake’s Startup Noise Checklist

Before leaving, Jake notes:

-

Ignition sound quality

-

Inducer pitch and stability

-

Cabinet vibration points

-

Blower ramp noise

-

Supply/return reactions

These notes become:

-

A baseline

-

A defense against callbacks

-

A roadmap for future techs

🚫 The Three Noise Mistakes Jake Sees Most

❌ Mistake #1: Waiting for homeowner complaints

Noise always starts earlier.

❌ Mistake #2: Assuming “normal furnace sounds”

Normal is specific — not vague.

❌ Mistake #3: Masking noise with settings

Delay hides. It doesn’t fix.

🧠 Why Sound Predicts Failure Better Than Numbers

Numbers tell you where you are.

Sound tells you where you’re headed.

Jake trusts sound because:

-

It’s immediate

-

It’s physical

-

It’s hard to fake

ASHRAE recognizes abnormal sound and vibration as early indicators of mechanical stress

(ASHRAE – HVAC Vibration & Noise Fundamentals).

🔚 Jake’s Final Word on the Sound Map

Every furnace writes a soundtrack on startup.

Most people ignore it.

Jake listens.

“If you learn the sounds,

you fix the problem before it learns how to break.”

The GR9S talks early.

Jake hears it.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Three Cycles or It’s Not Started: Jake’s Rule for Declaring a Furnace ‘Commissioned’