Most people think voltage is a yes-or-no question.

Is there power?

Yes.

Move on.

Jake knows that answer means nothing during startup.

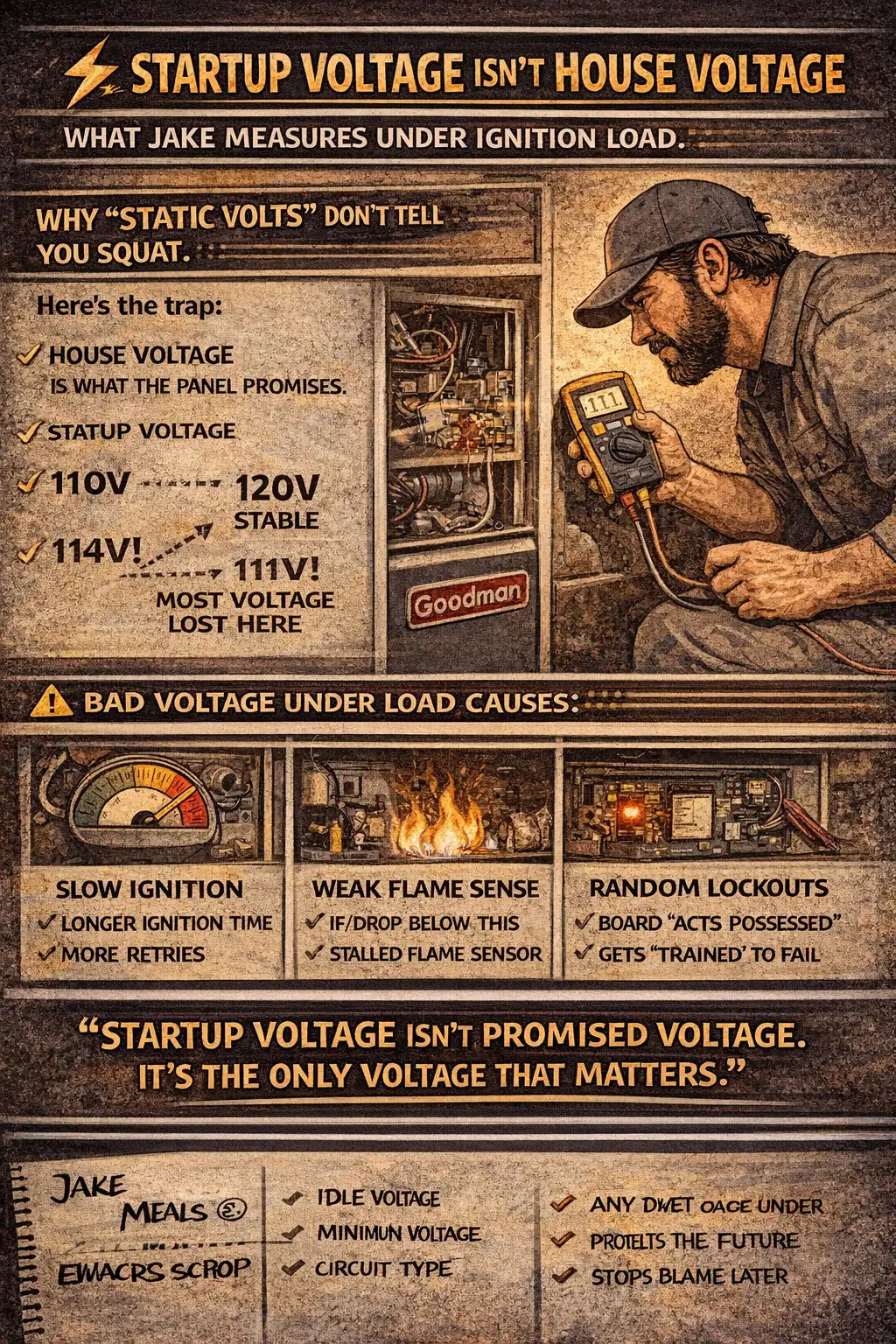

Because house voltage and startup voltage are not the same thing.

And the only voltage that matters to a furnace is what’s left when ignition actually pulls load.

This is where a huge number of “mystery” lockouts, flame failures, and board replacements really come from — not bad parts, but bad voltage under load that nobody ever measured.

This article breaks down why static voltage lies, what Jake checks during ignition on the Goodman GR9S800803BN, and how voltage problems train control boards to behave badly long before a code ever shows up.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🧠 Why Voltage Looks Fine — Until It Matters

Here’s the trap:

-

Multimeter reads 120V at idle

-

Furnace powers up

-

Lights work

-

Thermostat responds

Everyone relaxes.

Then ignition starts.

Suddenly:

-

Inducer motor draws current

-

Igniter ramps up

-

Control board powers safety circuits

That’s when voltage tells the truth.

“Voltage doesn’t fail quietly. It fails under stress.”

Jake doesn’t care what the voltage is when nothing is happening.

He cares what’s left when everything happens at once.

🔥 Ignition Is the Hardest Electrical Moment of Startup

Ignition is the electrical stress test of the furnace.

During ignition:

-

Current demand spikes

-

Resistance matters

-

Loose connections reveal themselves

-

Undersized wiring shows its limits

Jake watches voltage right at this moment, because:

-

Flame sensing is most sensitive here

-

Boards make timing decisions here

-

Pressure switches are most vulnerable here

If voltage dips now, the board remembers it.

📉 What Voltage Drop Actually Looks Like

Voltage drop isn’t always dramatic.

Jake routinely sees:

-

120V idle

-

114V during inducer start

-

109–112V during igniter warm-up

That’s enough to cause:

-

Slow ignition

-

Weak flame sense

-

Delayed proving

-

Intermittent retries

And still — no fault code.

HVAC School outlines how even modest voltage drops under load can disrupt ignition reliability

(HVAC School – Voltage Drop Basics).

🛠️ Where Jake Measures (And Why Location Matters)

Jake doesn’t measure voltage “somewhere nearby.”

He measures:

-

At the furnace terminals

-

During inducer operation

-

During igniter warm-up

-

During flame proving

Why?

Because voltage loss happens between the panel and the load.

Common loss points:

-

Long circuit runs

-

Undersized wire

-

Shared circuits

-

Loose neutrals

-

Poor grounding

Measuring at the breaker doesn’t show any of that.

🧲 Grounding: The Half of Voltage Everyone Ignores

Voltage needs a clean path out, not just in.

Bad grounding causes:

-

Flame sensor instability

-

Control board noise

-

Random lockouts

-

False error codes

Jake always checks:

-

Ground integrity

-

Bonding quality

-

Neutral-to-ground relationship

A furnace with bad ground behaves like it’s haunted.

“Bad ground makes good voltage useless.”

🧠 How Control Boards React to Marginal Voltage

Control boards don’t panic when voltage dips.

They adapt.

During early cycles, the board may:

-

Extend ignition timing

-

Tolerate slower flame proving

-

Retry more often

-

Delay fault recognition

That sounds helpful — until conditions change slightly.

Then:

-

Lockouts appear randomly

-

Flame sense becomes inconsistent

-

Boards get blamed unfairly

Jake has saved countless boards by fixing voltage instead of replacing parts.

🔄 Why Voltage Problems Show Up Weeks Later

Voltage issues rarely cause immediate failure.

Instead, they:

-

Stress components

-

Train the board poorly

-

Accelerate igniter wear

-

Degrade flame sensing

Weeks later:

-

The igniter fails “early”

-

The board “acts weird”

-

The furnace locks out “randomly”

The voltage problem was there on day one.

Nobody looked.

⚠️ Shared Circuits: Startup’s Silent Killer

Jake flags any furnace sharing a circuit with:

-

Freezers

-

Sump pumps

-

Garage outlets

-

Lighting loads

Why?

Because simultaneous demand causes:

-

Sudden voltage sag

-

Unpredictable startup behavior

-

Inconsistent ignition

The furnace might start fine — until something else turns on.

NEC guidance strongly discourages shared loads for fixed HVAC equipment

(NFPA 70 – National Electrical Code).

🧪 Jake’s Startup Voltage Test Routine

Jake’s process is simple but deliberate:

-

Measure idle voltage

-

Start furnace

-

Watch voltage during inducer start

-

Watch voltage during igniter warm-up

-

Observe voltage during flame proving

-

Check recovery after ignition

He doesn’t rush.

He watches patterns.

Patterns tell the truth.

📝 What Jake Documents Before He Leaves

Jake writes down:

-

Idle voltage

-

Minimum voltage under ignition

-

Circuit type

-

Ground condition

-

Any corrections made

That documentation:

-

Explains future behavior

-

Protects the furnace

-

Stops blame later

🚫 The Three Voltage Mistakes Jake Sees Most

❌ Mistake #1: Trusting idle voltage

Idle voltage is meaningless.

❌ Mistake #2: Blaming parts before power

Parts fail when power abuses them.

❌ Mistake #3: Ignoring ground quality

Ground problems mimic board failures perfectly.

🔚 Jake’s Final Word on Startup Voltage

Voltage doesn’t need to disappear to cause problems.

It just needs to dip at the wrong moment.

Startup is that moment.

“House voltage is what the panel promises.

Startup voltage is what the furnace actually gets.”

Jake measures what matters.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The Sound Map: Jake’s Startup Noise Checklist for the GR9S Cabinet