If a high-efficiency furnace makes water, nobody panics.

It’s supposed to.

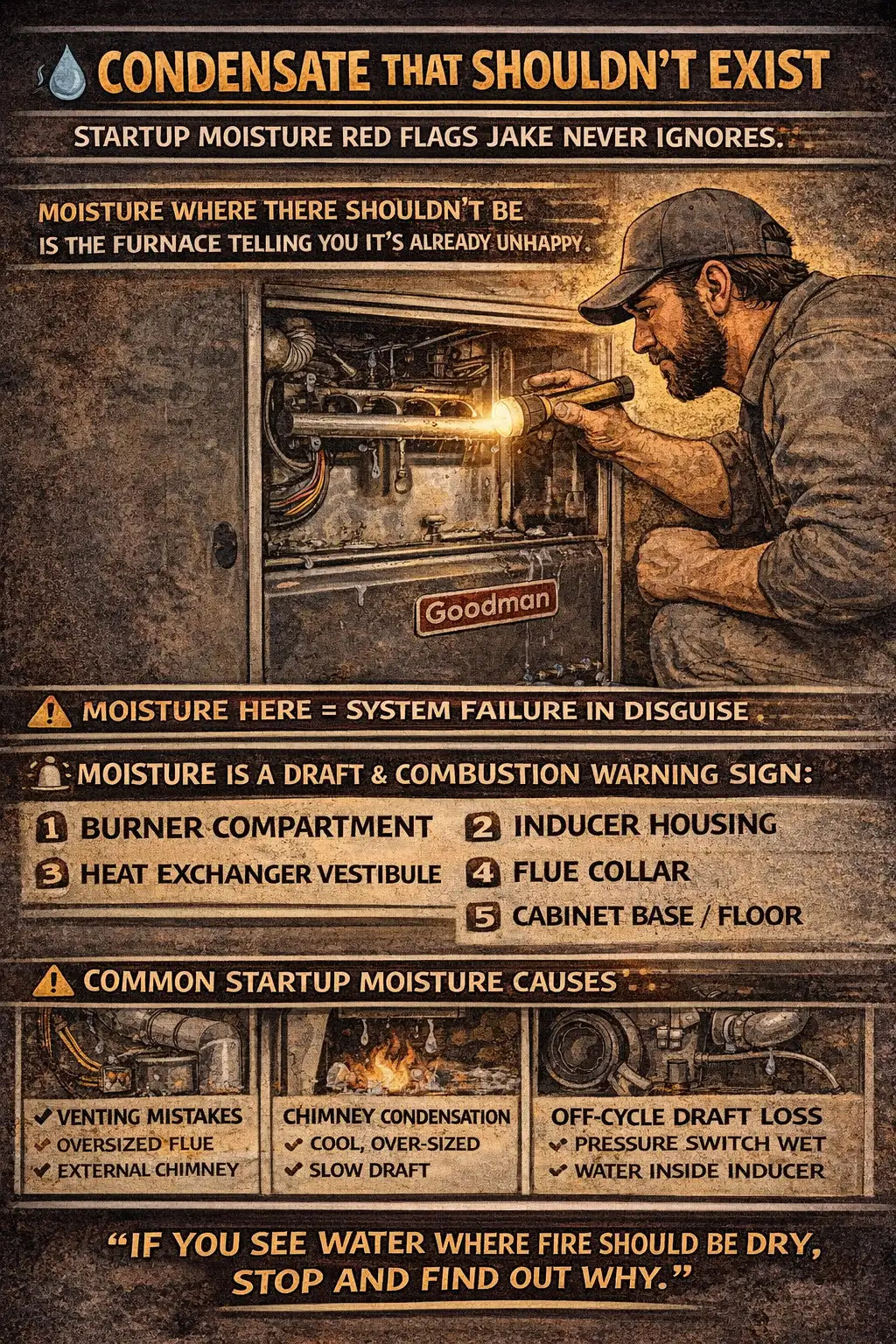

But when a non-condensing furnace shows moisture during startup?

Jake doesn’t shrug.

He stops everything.

Because condensate that shouldn’t exist is never harmless. It’s a symptom — and startup is when that symptom is loudest, clearest, and easiest to diagnose.

This article breaks down where moisture should never appear, why startup condensation is one of the most overlooked red flags in the field, and how Jake uses early moisture clues to prevent venting failures, corrosion, and callbacks months down the line — especially on furnaces like the Goodman GR9S800803BN (80% AFUE).

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🚨 Why Startup Moisture Is More Important Than Mid-Season Moisture

Moisture later in the season can be messy.

Moisture at startup is diagnostic.

During startup:

-

The heat exchanger is cold

-

Venting hasn’t warmed

-

Draft is weakest

-

Flue gases are at their most unstable

That’s when condensation shows you exactly where the system is failing to establish proper draft or heat transfer.

“Startup moisture is the furnace telling you where it’s struggling — before it learns how to hide it.”

🔍 Where Moisture Should Never Appear on an 80% Furnace

Jake has a short, non-negotiable list.

On a furnace like the GR9S800803BN, moisture should never be present in or around:

-

The burner compartment

-

The inducer housing

-

The heat exchanger vestibule

-

The flue collar

-

The cabinet base

-

The supply plenum connection

Any moisture in these areas during startup means something upstream is wrong.

Not “might be wrong.”

Wrong.

🌡️ The Cold Heat Exchanger Effect (And Why It Matters)

At startup, the heat exchanger is cold steel.

When hot combustion gases hit cold metal:

-

Flue gases cool rapidly

-

Water vapor condenses sooner

-

Draft establishment is delayed

This is normal — to a point.

What Jake watches is:

-

How fast moisture appears

-

Where it appears

-

Whether it disappears as the system warms

Condensation that lingers or spreads after warm-up is the red flag.

🌬️ Venting Mistakes That Reveal Themselves Through Moisture

Startup moisture is often a venting problem in disguise.

Jake commonly traces early condensation to:

-

Oversized flue pipes

-

Excessive horizontal runs

-

Insufficient vertical rise

-

Cold exterior chimneys

-

Improper vent connectors

These issues slow draft, allowing flue gases to cool too quickly and drop moisture where they shouldn’t.

NFPA 54 outlines minimum venting practices specifically to prevent these conditions

(NFPA 54 – National Fuel Gas Code).

🧱 Chimneys: The Silent Moisture Multiplier

Exterior chimneys are a common culprit.

During startup:

-

Masonry is cold

-

Draft is weak

-

Moisture condenses rapidly

-

Acidic byproducts form

Jake pays close attention to:

-

Chimney location (interior vs. exterior)

-

Liner presence

-

Evidence of past moisture damage

Startup moisture in these systems often predicts:

-

Rusted connectors

-

Deteriorating liners

-

Long-term corrosion

Once corrosion starts, it doesn’t stop politely.

⚠️ Why Moisture Near the Inducer Is a Big Deal

The inducer is not designed to handle liquid water.

If Jake sees moisture:

-

Inside the inducer housing

-

At pressure switch tubing

-

Around inducer seams

He stops and investigates immediately.

Why?

Because moisture here often indicates:

-

Backdrafting

-

Delayed draft establishment

-

Improper vent sizing

Left alone, this leads to:

-

Pressure switch issues

-

Inducer motor failure

-

Random lockouts later

🔥 Combustion Quality and Moisture Are Linked

Moisture doesn’t just come from venting.

Poor combustion can increase water vapor production.

Jake looks at:

-

Flame stability

-

Flame color at startup

-

Gas pressure accuracy

-

Burner alignment

Incomplete combustion increases moisture and accelerates condensation — especially during cold starts.

That’s why Jake never evaluates moisture without also watching flame behavior.

🛠️ Jake’s Startup Moisture Inspection Routine

Jake doesn’t wait for drips.

He actively checks:

-

Burner compartment (visual + smell)

-

Inducer housing seams

-

Flue connector joints

-

Cabinet base

-

Surrounding floor and insulation

All before the furnace has fully warmed.

If moisture is present, he diagnoses before proceeding — not after the homeowner complains.

🧪 Why “It Dried Up” Doesn’t Mean “It’s Fine”

One of the most dangerous assumptions:

“It was wet at first, but it dried up.”

That usually means:

-

The system warmed enough to mask the issue

-

Draft improved temporarily

-

Moisture moved somewhere less visible

The problem didn’t go away.

It relocated.

ASHRAE has long noted that intermittent condensation is a key indicator of venting and combustion mismatches

(ASHRAE – Combustion & Venting Fundamentals).

🧱 Long-Term Damage Caused by Ignored Startup Condensation

Unchecked startup moisture leads to:

-

Corroded heat exchangers

-

Rusted burners

-

Failed pressure switches

-

Vent connector deterioration

-

Indoor air quality risks

None of these fail immediately.

They fail expensively.

📝 What Jake Documents When He Sees Moisture

Before leaving, Jake records:

-

Location of moisture

-

Startup conditions

-

Venting configuration

-

Chimney type

-

Corrective actions taken

This documentation:

-

Protects the homeowner

-

Protects the installer

-

Creates a baseline for future inspections

🚫 The Three Moisture Mistakes Jake Sees Most

❌ Mistake #1: Assuming all moisture is “normal”

Normal has boundaries.

❌ Mistake #2: Ignoring moisture that disappears

Disappearing doesn’t mean resolved.

❌ Mistake #3: Blaming humidity instead of venting

Indoor humidity doesn’t wet inducer housings.

🧠 Why Jake Treats Moisture as a Startup Alarm

Noise can lie.

Temperature can mislead.

Codes can stay silent.

Moisture doesn’t.

“Water only shows up when physics is unhappy.”

Jake listens.

🔚 Jake’s Final Word on Condensate That Shouldn’t Exist

If an 80% furnace is making water where it shouldn’t, it’s not being picky — it’s warning you.

Startup moisture is the system’s earliest, clearest distress signal.

Ignore it, and the furnace will keep talking — just louder, later, and more expensively.

“If you see water where fire should be dry,

stop and find out why.”

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Startup Voltage Isn’t House Voltage: What Jake Measures Under Ignition Load