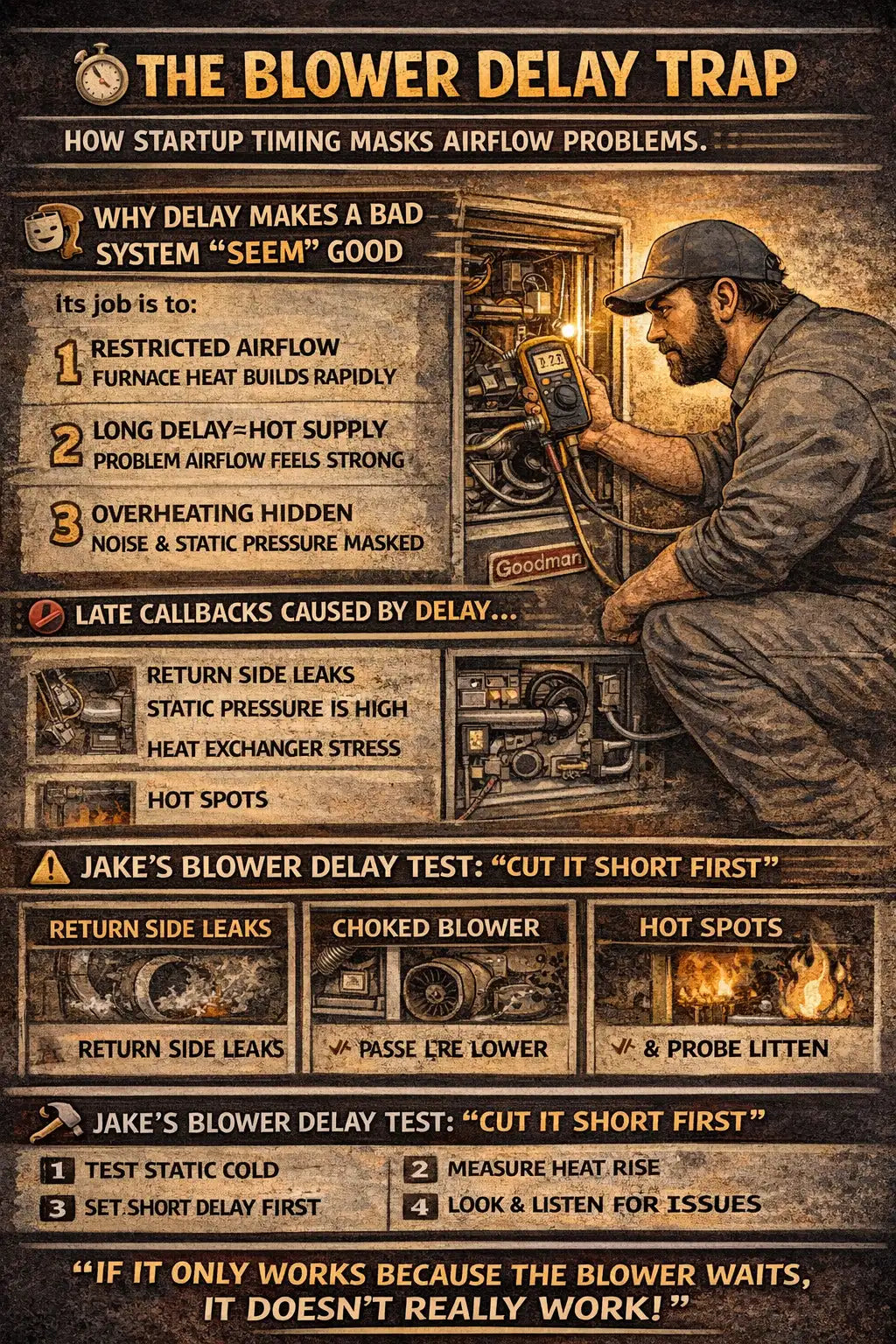

If there’s one setting that lies better than bad static pressure, it’s blower delay.

Most installers think blower delay is about comfort.

Jake knows it’s about covering mistakes.

A long blower delay can make a bad airflow system feel fine — at least at first. Warm air hits the registers, homeowners smile, and everyone assumes the job is done.

Weeks later, the callbacks start.

This article breaks down how blower delay timing masks airflow problems, why it’s one of the most abused startup settings, and how Jake uses blower delay to expose issues instead of hiding them — especially on furnaces like the Goodman GR9S800803BN.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🧠 What Blower Delay Is Supposed to Do

Blower delay exists for a legitimate reason.

Its job is to:

-

Prevent cold air blasts at startup

-

Allow the heat exchanger to warm slightly

-

Improve perceived comfort

-

Reduce short-term condensation risk

That’s it.

It was never designed to:

-

Fix undersized ducts

-

Compensate for high static pressure

-

Silence airflow noise

-

Hide return-side restrictions

But that’s exactly how it gets used.

🎭 How Blower Delay Becomes a Disguise

Here’s the trap:

-

Airflow is restricted

-

Heat builds quickly in the heat exchanger

-

Blower delay holds airflow back

-

Temperature rises fast

-

Supply air feels hot

-

System “feels strong”

In reality:

-

The blower is starving

-

Static pressure is high

-

Heat exchanger stress increases

-

The system is overheating quietly

“Hot air isn’t proof of good airflow.

It’s often proof of bad airflow.”

⏳ Why Longer Delays Make Bad Systems Look Better

Long blower delays exaggerate temperature rise.

That does three dangerous things:

-

Makes airflow feel more powerful than it is

-

Delays noise until after startup

-

Pushes problems into later cycles

By the time the blower starts:

-

Metal has expanded

-

Pressure has equalized slightly

-

Noise is reduced

-

The worst restriction symptoms are muted

Jake calls this airflow theater.

🌡️ Temperature Rise: The Metric Everyone Misreads

Temperature rise is often treated as a success metric.

But Jake looks at how it gets there.

High temperature rise with:

-

Long blower delay

-

High static pressure

-

Restricted return

…is not efficiency. It’s stress.

ASHRAE has long noted that improper airflow skews temperature rise readings and masks system inefficiencies

(ASHRAE – Airflow & Heat Transfer Fundamentals).

🛠️ Jake’s Rule: Delay Never Gets Set Until Airflow Is Proven

Jake refuses to finalize blower delay until:

-

Static pressure is measured cold

-

Return and supply are evaluated

-

Filter resistance is known

-

Blower speed is confirmed

Only then does he adjust delay — and often shortens it on problem systems.

“Delay should follow airflow, not compensate for it.”

🔊 Noise That Shows Up Late Is Still an Airflow Problem

One of the most common callbacks Jake sees:

“It was quiet at first. Now it’s loud.”

That’s blower delay at work.

Restricted airflow causes:

-

Whistling

-

Rumble

-

Cabinet vibration

But delay hides it until:

-

The blower ramps fully

-

Filters load

-

Ducts heat and flex

The noise didn’t develop later.

It was just delayed.

ACCA airflow guidance consistently warns against using operational settings to mask duct deficiencies

(ACCA Manual D Overview).

🌬️ The Return Side Suffers the Most

Blower delay hurts return-side diagnosis more than supply.

Why?

-

Return restrictions don’t announce themselves with hot air

-

Delay increases negative pressure

-

Leaks pull from unintended spaces

-

Dust bypass increases

By the time the blower starts, the system has already built a false pressure balance.

Jake checks return static before delay effects show up.

⚠️ How Blower Delay Accelerates Heat Exchanger Stress

This part gets ignored — until it’s expensive.

Long delays mean:

-

Heat exchanger sees higher peak temperatures

-

Uneven expansion occurs

-

Metal stress increases cycle after cycle

The furnace doesn’t fail immediately.

It ages faster.

The U.S. Department of Energy notes that improper airflow is a leading contributor to premature furnace component failure

(DOE – Furnace Operation & Airflow).

🧪 Jake’s Blower Delay Test During Startup

Jake doesn’t guess.

He:

-

Starts with default delay

-

Measures cold static pressure

-

Observes ignition and heat buildup

-

Shortens delay temporarily

-

Listens and measures again

If problems suddenly appear when delay is reduced, the delay was hiding something.

That’s the point.

🚫 The Three Blower Delay Mistakes Jake Sees Most

❌ Mistake #1: Using delay to “fix” noise

Noise is airflow asking for help.

❌ Mistake #2: Maximizing delay for comfort alone

Comfort without durability is temporary.

❌ Mistake #3: Never revisiting delay after startup

Delay is not a set-it-and-forget-it feature.

📝 What Jake Documents About Blower Timing

Before leaving, Jake notes:

-

Final blower delay setting

-

Static pressure readings

-

Temperature rise behavior

-

Noise observations

This ensures:

-

Future techs know the intent

-

Homeowners aren’t misled

-

Problems don’t get blamed on the furnace later

🧠 Why Delay Problems Show Up Weeks Later

Blower delay doesn’t break systems instantly.

It:

-

Hides restriction

-

Increases stress gradually

-

Allows dirt to load filters faster

-

Raises operating temperatures quietly

Weeks later, symptoms appear — and nobody connects them to delay.

Jake does.

🔚 Jake’s Final Word on the Blower Delay Trap

Blower delay should smooth comfort — not rewrite physics.

If a system only works because the blower waits, it doesn’t really work.

“Delay should polish a good system.

Not disguise a bad one.”

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Condensate That Shouldn’t Exist: Startup Moisture Red Flags Jake Never Ignores