Most installers set gas pressure once, tighten the cap, and walk away.

Jake doesn’t.

Because gas pressure doesn’t stay where you set it — it moves.

And it moves the most after the furnace has been running hot.

Jake learned this the hard way early in his career: a furnace that looked perfect cold, passed every startup checklist, and still came back with noise complaints, overheating symptoms, and flame instability weeks later.

The problem wasn’t the furnace.

It was gas pressure drift — and it only showed itself after heat soak.

This article explains why gas pressure changes after warm-up, what Jake looks for on the Goodman GR9S800803BN, and why skipping the hot recheck creates failures that don’t look like gas problems at all.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

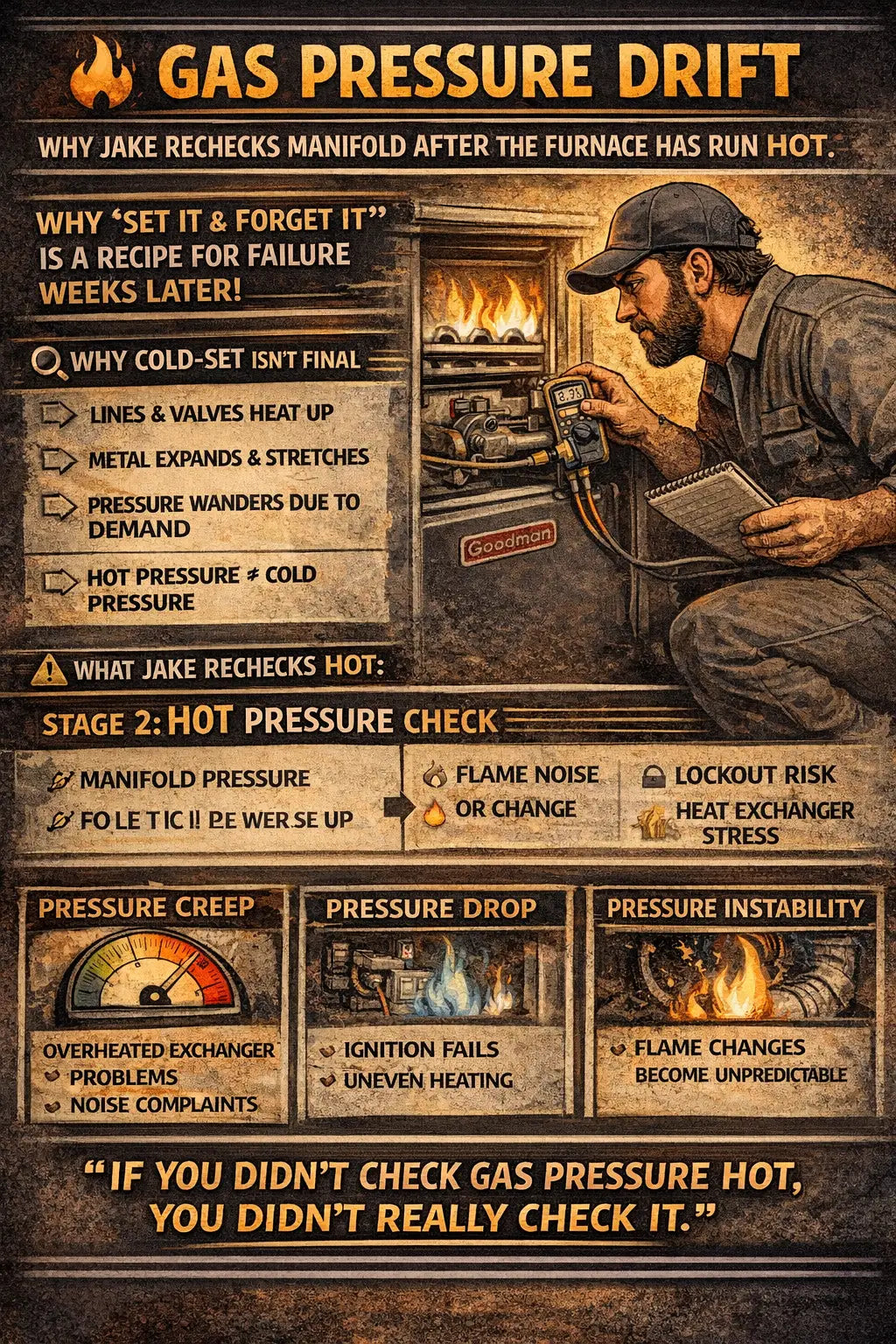

⏱️ Why Cold-Set Gas Pressure Isn’t the Finish Line

Cold gas pressure is a starting point — not a verdict.

At initial startup:

-

Gas lines are cool

-

Regulators haven’t stabilized

-

Valves haven’t expanded

-

Combustion components are at ambient temperature

Everything behaves politely.

But once the furnace runs:

-

Metal expands

-

Regulators respond differently

-

Valve tolerances shift

-

Supply pressure fluctuates under sustained demand

That’s when the real pressure shows up.

“Cold pressure is theory. Hot pressure is reality.”

🌡️ Heat Soak Changes the Gas System More Than People Think

Heat soak doesn’t just affect airflow and cabinets — it affects fuel delivery.

As the system heats:

-

Gas valve bodies expand

-

Springs and diaphragms react to temperature

-

Internal resistance changes slightly

-

Supply lines respond to demand over time

Small changes matter.

A drift of even 0.2–0.3 inches WC can:

-

Alter flame shape

-

Increase noise

-

Stress the heat exchanger

-

Create delayed ignition patterns

Jake waits for the furnace to reach full operating temperature before trusting the reading.

📏 What “Drift” Actually Looks Like in the Field

Gas pressure drift usually shows up as one of three patterns:

🔺 Pressure Creep (Rising)

-

Flame gets louder over time

-

Slight yellowing appears hot

-

Burner noise increases

-

Heat exchanger runs hotter than expected

🔻 Pressure Drop (Falling)

-

Flame softens after warm-up

-

Flame sensor readings weaken

-

Delayed ignition returns on later cycles

-

Lockouts appear inconsistently

🔄 Pressure Instability

-

Pressure fluctuates between cycles

-

Flame changes character hot vs. cold

-

Combustion becomes unpredictable

Jake sees all three — but only when he checks hot.

🛠️ Jake’s Two-Stage Gas Pressure Method

Jake never sets pressure just once.

Stage 1: Cold Set

-

Verify supply pressure

-

Set manifold to manufacturer spec

-

Confirm clean ignition and flame shape

Then Jake waits.

Stage 2: Hot Recheck

-

Let the furnace run long enough to heat soak

-

Re-measure manifold pressure

-

Observe flame behavior under sustained heat

-

Make final micro-adjustments if needed

This method aligns with manufacturer guidance that emphasizes operating-condition verification, not just static setup

(Goodman Furnace Technical Information).

🔥 Flame Tells You Pressure Is Drifting Before the Gauge Does

Jake doesn’t stare at the manometer alone.

He watches:

-

Flame length changes

-

Flame noise increase

-

Flame lift or pull

-

Color shift under sustained heat

If flame behavior changes but pressure still “looks okay,” Jake checks again.

“The flame reacts before the gauge confesses.”

🧱 Why the GR9S Makes Pressure Drift Easier to Spot

The Goodman GR9S800803BN is single-stage and straightforward.

That’s an advantage.

No modulation means:

-

No algorithm smoothing mistakes

-

No staging to hide drift

-

Direct cause-and-effect behavior

If pressure is off, the GR9S shows it honestly.

Jake trusts furnaces like this because they don’t lie politely.

⚠️ How Gas Pressure Drift Damages Heat Exchangers Quietly

One of the biggest risks of unchecked drift is thermal stress.

Over-firing causes:

-

Excessive heat exchanger temperature

-

Uneven expansion

-

Long-term metal fatigue

Under-firing causes:

-

Flame instability

-

Longer run times

-

Uneven heating patterns

Both shorten exchanger life — without tripping immediate safeties.

ASHRAE has long documented the relationship between firing rate and heat exchanger stress

(ASHRAE Heating Systems Fundamentals).

🔊 Noise Complaints That Are Really Gas Pressure Problems

Jake gets called back for:

-

“The furnace got louder”

-

“It sounds harsher now”

-

“It didn’t do that the first week”

Nine times out of ten, the cause is:

-

Pressure drift after repeated heat cycles

-

Not a loose panel

-

Not a bad blower

-

Not a defective furnace

Gas pressure changed — and nobody rechecked it hot.

📝 What Jake Documents After Hot Gas Verification

Before he leaves, Jake records:

-

Cold manifold pressure

-

Hot manifold pressure

-

Supply pressure under load

-

Flame behavior notes

-

Final adjustment position

This protects:

-

The homeowner

-

The installer

-

The equipment

And it shuts down arguments later.

🚫 The Three Gas Pressure Mistakes Jake Sees Most

❌ Mistake #1: Setting pressure once and trusting it

Gas doesn’t freeze in place.

❌ Mistake #2: Adjusting pressure cold to fix hot symptoms

That’s chasing shadows.

❌ Mistake #3: Ignoring flame noise

Noise is combustion talking.

🧠 Why Drift Causes Problems Weeks — Not Minutes — Later

Gas pressure drift doesn’t usually cause instant failure.

Instead, it:

-

Slightly increases stress

-

Slightly worsens ignition

-

Slightly alters combustion

Those “slightlies” add up.

Weeks later:

-

Lockouts appear

-

Heat complaints start

-

Parts get blamed

Jake fixes it before the story gets complicated.

🔚 Jake’s Final Word on Gas Pressure Drift

Gas pressure isn’t wrong because it moved.

It’s wrong because nobody checked it when it mattered.

Jake doesn’t trust cold readings, first impressions, or factory stickers alone.

“If you didn’t check gas pressure hot,

you didn’t really check it.”

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The Blower Delay Trap: How Startup Timing Masks Airflow Problems