A furnace doesn’t start fresh every time.

That’s the mistake most installers make.

They think the control board is just a referee — watching switches, throwing faults, resetting every cycle like nothing happened before.

Jake knows better.

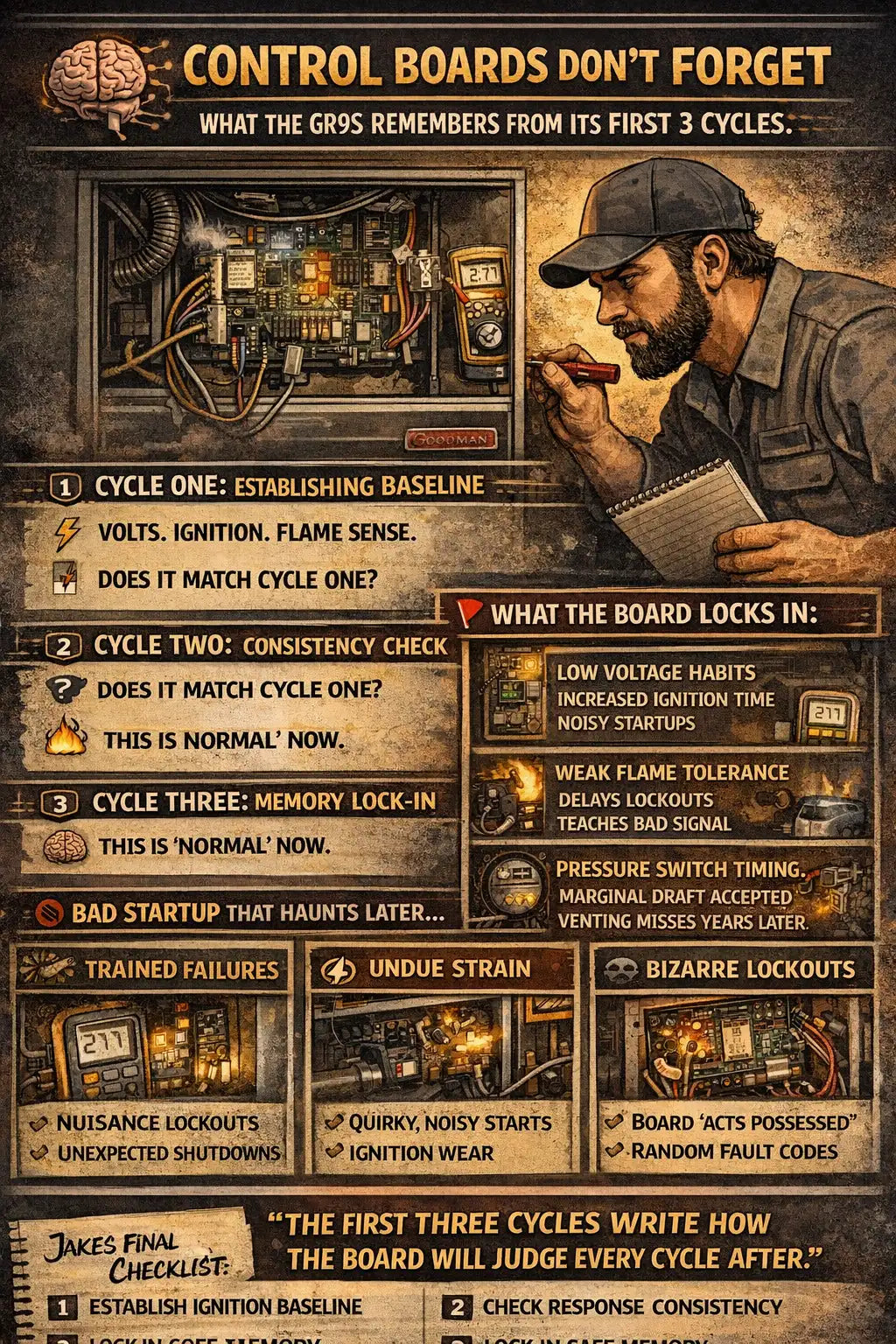

Modern furnace control boards observe, react, adapt, and remember. Especially during the first three startup cycles, when the system is learning how the house behaves, how stable the utilities are, and how safely it can operate under real conditions.

On the Goodman GR9S800803BN, those first cycles matter more than most people realize. Not because it’s complicated — but because it’s honest.

This article breaks down what the control board actually “remembers,” why sloppy startup creates long-term issues, and how Jake makes sure the furnace learns the right lessons from day one.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🕒 Why the First Three Cycles Matter More Than the First Three Years

The first cycle proves the furnace can run.

The second cycle proves it can repeat.

The third cycle tells the board what “normal” looks like.

After that, the board starts comparing everything it sees to those early benchmarks.

Jake explains it this way:

“The board doesn’t just ask can I fire?

It asks is this how firing is supposed to feel?”

If ignition, voltage, flame sense, or pressure are unstable early, the board doesn’t forget — it just adjusts its expectations.

And that’s where trouble begins.

🔁 Cycle One: Establishing Baseline Behavior

The first cycle is where the control board observes raw conditions:

-

Incoming voltage

-

Ignition timing

-

Flame sensor response

-

Pressure switch behavior

-

Inducer performance

Jake wants this cycle boringly perfect.

Because if the board sees:

-

Weak flame signal

-

Borderline voltage

-

Slow pressure switch closure

…it doesn’t always throw a code.

Instead, it quietly treats that behavior as acceptable.

That’s how marginal systems get normalized.

🔂 Cycle Two: Consistency Check

By the second cycle, the board starts comparing:

-

Was ignition timing the same?

-

Did flame prove as quickly?

-

Did the pressure switch close at the same point?

-

Did voltage dip under load again?

Jake watches this cycle closely because inconsistency is louder than failure.

A furnace that struggles differently each cycle is harder for the board to interpret — and harder to protect.

This is often where future nuisance lockouts are born.

🔃 Cycle Three: Memory Lock-In

The third cycle is where the board decides:

“This is what normal operation looks like.”

If the first three cycles include:

-

Unstable gas pressure

-

Fluctuating voltage

-

Weak grounding

-

Poor airflow conditions

…the board adapts its tolerance around those flaws.

That adaptation can look like:

-

Delayed fault recognition

-

Repeated retries

-

Flame sensor sensitivity drift

-

Lockouts that appear “random” months later

Jake calls these trained failures.

⚡ Voltage: What the Board Learns About Power Quality

Control boards care deeply about voltage — especially during ignition.

During early cycles, the board observes:

-

Incoming line voltage

-

Voltage drop during inducer and ignition

-

Recovery speed after load

If voltage is marginal early, the board may:

-

Extend ignition attempts

-

Adjust flame proving expectations

-

Become more sensitive to minor dips later

Jake verifies voltage under load, not at idle, following accepted electrical best practices

(HVAC School – Voltage Drop Basics).

“Bad power teaches the board bad habits.”

🔥 Flame Sensing: Early Weak Signals Have Long Memories

Flame sensors don’t just detect flame — they teach the board what a healthy flame signal looks like.

If early cycles produce:

-

Weak microamp readings

-

Intermittent flame sensing

-

Dirty sensor contact

…the board adapts by accepting weaker signals as normal.

Later, when the sensor degrades slightly (as all do), the board may:

-

Miss flame loss

-

Retry excessively

-

Lock out unexpectedly

Jake ensures strong, clean flame sensing from cycle one using manufacturer guidance

(Goodman Furnace Service Information).

🌬️ Pressure Switch Behavior: Timing Is Data

Pressure switches don’t just open and close — they close within a timeframe the board expects.

Early cycles establish:

-

How quickly draft is achieved

-

How stable pressure remains

-

How the system reacts to small fluctuations

If draft is marginal early:

-

The board may accept slow closure

-

Later venting issues become harder to diagnose

-

Lockouts appear weather-dependent

Jake watches pressure switch timing closely, especially on cold startups.

🔄 Why Power Interruptions During Startup Are a Big Deal

One of Jake’s biggest red flags?

Power cycling a furnace repeatedly during initial startup.

Each interruption:

-

Resets logic without resetting conditions

-

Confuses early learning cycles

-

Creates inconsistent baselines

That’s why Jake:

-

Avoids unnecessary power interruptions

-

Completes full cycles cleanly

-

Lets the board finish what it started

This aligns with general control system commissioning principles

(ASHRAE – HVAC Control Systems Overview).

🧱 The GR9S Board: Simple, but Not Forgetful

The Goodman GR9S800803BN uses a straightforward control board — no Wi-Fi, no modulation, no AI.

That simplicity is an advantage.

It means:

-

Fewer variables

-

Clear cause-and-effect

-

Honest feedback

But it also means startup quality matters more, because the board won’t “optimize around” bad conditions.

Jake respects that.

📝 What Jake Documents After the First Three Cycles

Before he leaves, Jake records:

-

Ignition timing consistency

-

Flame sensor readings

-

Voltage under load

-

Pressure switch behavior

-

Any anomalies across cycles

This documentation becomes:

-

A baseline for future service

-

Proof of proper commissioning

-

Protection against blame later

🚫 The Three Control Board Mistakes Jake Sees Most

❌ Mistake #1: Declaring success after one cycle

One pass proves nothing.

❌ Mistake #2: Ignoring borderline behavior

“Almost fine” becomes “always broken.”

❌ Mistake #3: Resetting power instead of fixing causes

Boards remember patterns — not excuses.

🔚 Jake’s Final Word on Furnace Memory

Control boards don’t hold grudges.

They hold patterns.

What you teach them in the first three cycles becomes the lens through which they judge everything afterward.

“A furnace never forgets how it was introduced to the house.

Make sure the introduction is clean.”

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Gas Pressure Drift: Why Jake Rechecks Manifold After the Furnace Has Run Hot