Most airflow problems don’t start loud.

They start quiet — and they start early.

By the time a furnace has been running for ten minutes, the cabinet is warm, metal has expanded, draft has stabilized, and airflow has already adjusted itself enough to hide the real problem.

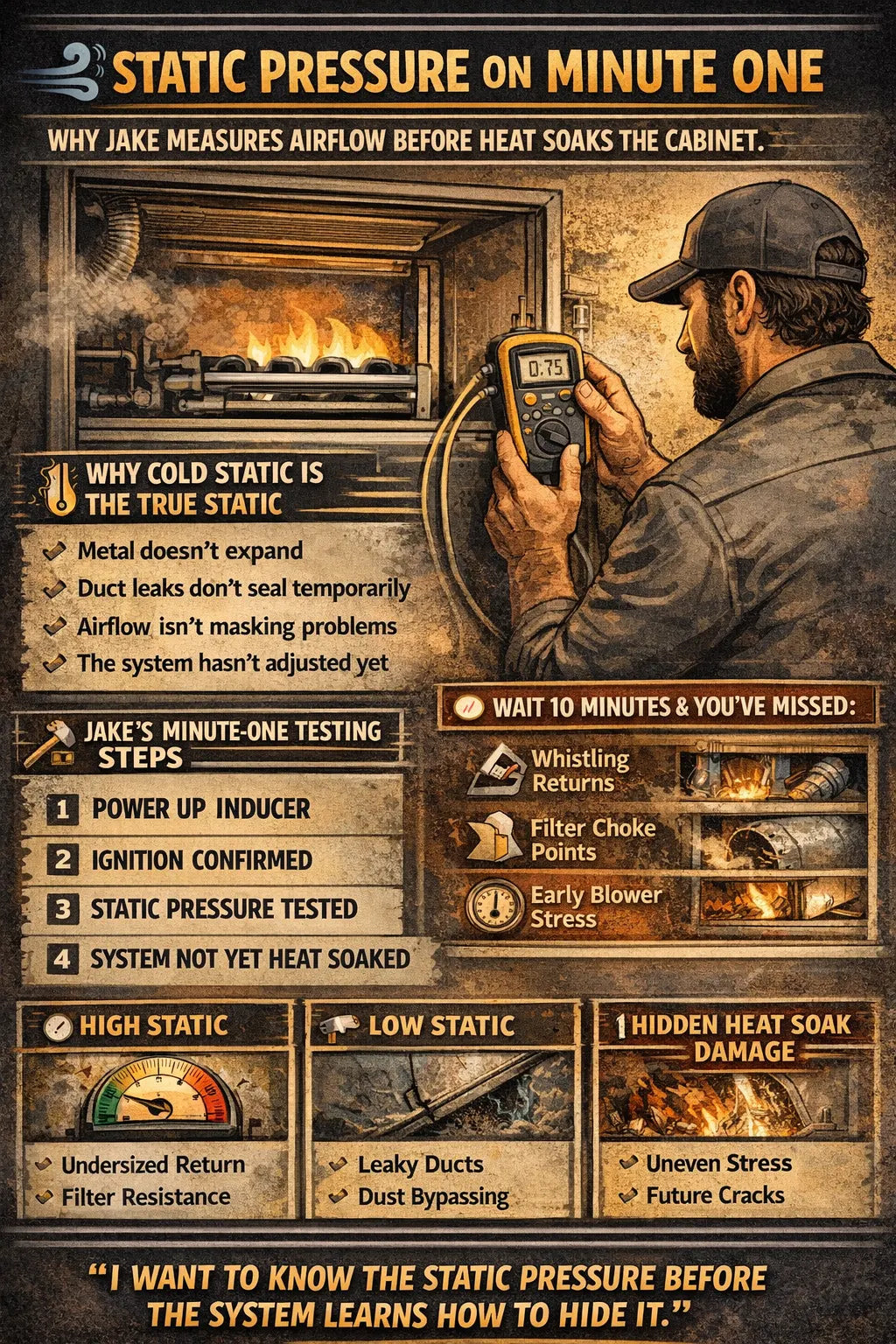

That’s why Jake doesn’t wait.

He measures static pressure on minute one, before heat soak, before comfort, before the blower “settles in.” Because that first reading tells him whether the system is breathing correctly — or just coping.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

This article breaks down why early static pressure matters, how Jake measures it on startup, and why waiting even five minutes can cost you years of furnace life.

⏱️ Why Minute One Is the Only Honest Airflow Snapshot

Airflow behaves differently when everything is cold.

At startup:

-

The heat exchanger hasn’t expanded

-

The cabinet hasn’t pressurized

-

Duct metal hasn’t flexed

-

Blower performance hasn’t been altered by temperature

Once heat builds:

-

Restrictions soften

-

Pressure redistributes

-

Blower curves change

-

Bad ductwork looks “acceptable”

Jake wants airflow before the system adapts.

“Warm metal forgives mistakes. Cold metal exposes them.”

📏 What Static Pressure Really Measures (And What It Doesn’t)

Static pressure isn’t airflow.

It’s resistance.

Jake explains it simply:

-

Airflow is how much air moves

-

Static pressure is how hard the blower has to work to move it

High static pressure means:

-

Restricted ducts

-

Undersized returns

-

Overloaded filters

-

Choked coils

-

Bad transitions

Low static pressure (yes, that’s a problem too) can mean:

-

Air leaks

-

Bypassed filters

-

Poor sealing

-

Incomplete duct paths

Jake isn’t chasing a number — he’s reading system stress.

🧠 Why Heat Soak Changes the Reading

Heat soak changes everything.

As the furnace warms:

-

The cabinet expands slightly

-

Seams seal tighter

-

The heat exchanger restricts airflow differently

-

Blower motor efficiency shifts with temperature

That means:

-

A bad system can look “within spec” later

-

A marginal system hides future failures

-

Early warning signs disappear

Jake wants the system before it learns how to compensate.

🛠️ Jake’s Minute-One Static Pressure Method

Jake doesn’t rush — but he doesn’t wait either.

Here’s his startup sequence:

-

Power on

-

Inducer starts

-

Ignition confirmed

-

Static pressure ports checked immediately

-

Compare against blower capability, not just nameplate

He measures:

-

Return static

-

Supply static

-

Total external static pressure

All before the cabinet is heat soaked.

📊 Why Manufacturer Limits Aren’t the Whole Story

Yes, the Goodman GR9S800803BN has published static pressure limits.

Jake knows them — and respects them.

But here’s the reality:

A system can be within spec and still be:

-

Loud

-

Inefficient

-

Hard on the blower

-

Stressful on the heat exchanger

Jake compares:

-

Measured static

-

Blower speed setting

-

Filter type

-

Duct design reality

He uses manufacturer data as a boundary, not a finish line

(Goodman Technical Information).

🌪️ What High Static Looks Like on Minute One

Early high static pressure usually points to:

-

Undersized return ducts

-

Too few return grilles

-

High-MERV filters in tight systems

-

Poor plenum transitions

-

Coil mismatches

Jake flags it early because high static leads to:

-

Overheated heat exchangers

-

Blower motor strain

-

Noise complaints

-

Premature failure

“If the blower is struggling cold, it’s screaming hot.”

❄️ What Low Static Tells Jake Instead

Low static doesn’t mean “good.”

Jake sees low static when:

-

Air is bypassing filters

-

Ducts are leaking

-

Cabinets aren’t sealed

-

Returns are pulling from unintended spaces

This causes:

-

Dust issues

-

Comfort imbalance

-

Reduced heat transfer

-

False efficiency expectations

Jake fixes leaks before airflow numbers get celebrated.

🔊 Noise Is an Airflow Symptom, Not a Mystery

Jake listens while he measures.

Early static pressure problems often sound like:

-

Whistling at registers

-

Cabinet vibration

-

Filter noise

-

Return rumble

If noise shows up before heat, it’s airflow — not expansion.

This aligns with airflow best practices outlined by ACCA

🔄 Why Waiting Causes False Confidence

Here’s the trap:

A tech waits 10 minutes → static drops → system looks fine → tech leaves.

Weeks later:

-

Blower runs hotter

-

Filter loads faster

-

Heat exchanger sees uneven stress

-

Noise returns

-

Comfort complaints start

Jake avoids all of that by measuring before the system settles into bad habits.

📝 What Jake Documents From Minute-One Testing

Before he leaves, Jake records:

-

Cold static pressure readings

-

Filter type and size

-

Blower speed setting

-

Duct observations

This protects:

-

The installer

-

The homeowner

-

The furnace

And it gives future techs context instead of confusion.

🚫 The Three Static Pressure Mistakes Jake Sees Most

❌ Mistake #1: Measuring only after warm-up

You’re reading adaptation, not reality.

❌ Mistake #2: Ignoring return pressure

Supply numbers lie without return context.

❌ Mistake #3: Treating spec limits as goals

Passing isn’t the same as healthy.

🔚 Jake’s Final Word on Minute-One Airflow

Airflow problems don’t get better with time.

They just get quieter — until they don’t.

By measuring static pressure on minute one, Jake sees:

-

What the system is fighting

-

What the blower is enduring

-

What the furnace will remember

“If airflow is wrong cold, it’s wrong forever.

Heat just teaches it how to hide.”

🔗 External References

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Control Boards Don’t Forget: What the GR9S Remembers From Its First 3 Cycles