Most installers treat startup like a formality.

Jake treats it like a crime scene.

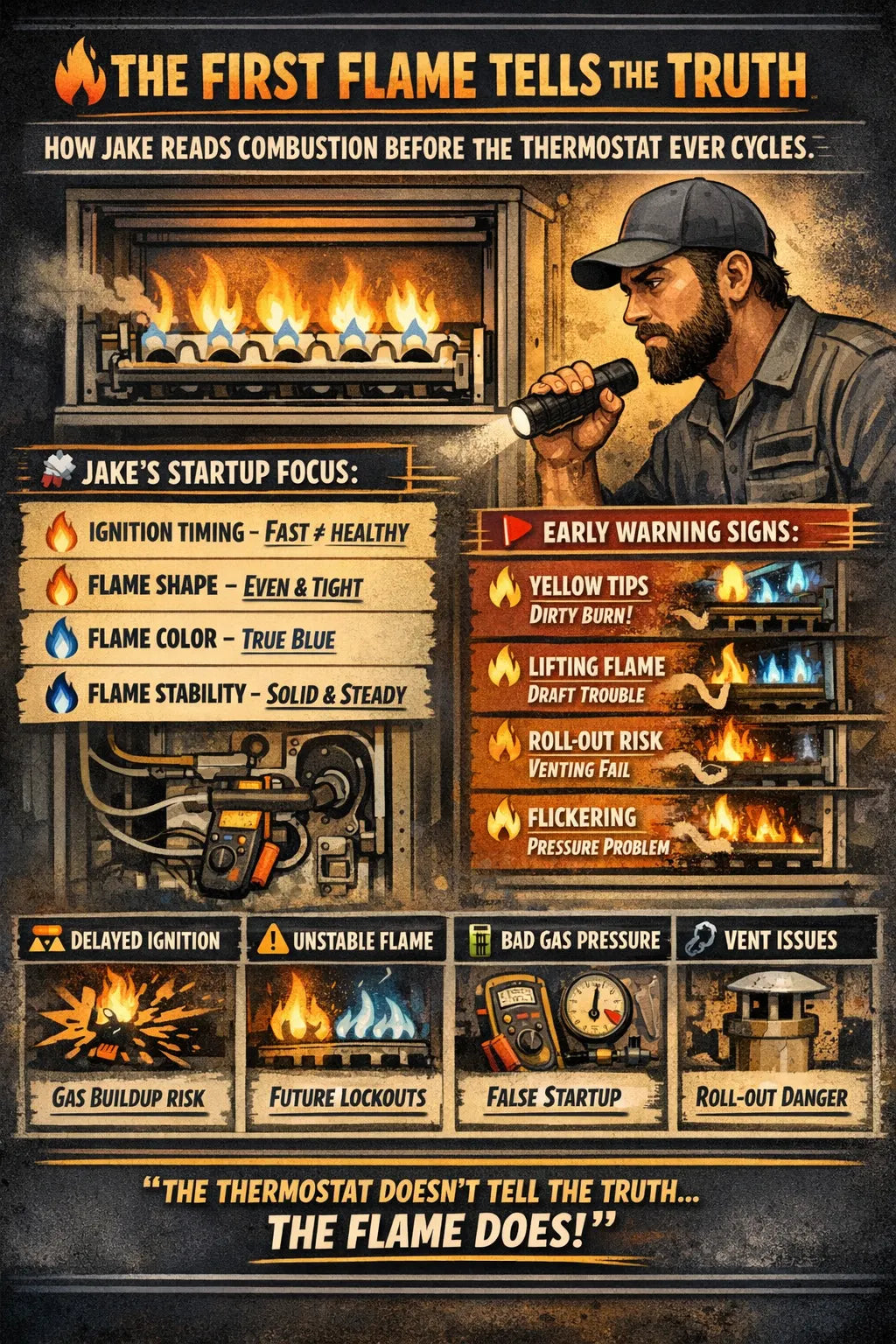

Before the thermostat ever calls for a second cycle… before the blower ramps… before the homeowner feels a single degree of warmth — the first flame has already told the entire story.

That first ignition doesn’t just mean the furnace “works.”

It reveals gas quality, airflow risk, venting mistakes, pressure imbalance, and future callbacks — all in under 30 seconds.

This article breaks down exactly how Jake reads combustion on startup, why it matters on the Goodman GR9S800803BN, and how missing these signs leads to problems that don’t show up until months later.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

👁️ Why the First Flame Is the Cleanest Data You’ll Ever Get

Once the furnace heats up, everything lies a little.

Metal expands.

Draft improves.

Pressure stabilizes.

Noise masks problems.

But the very first ignition happens when:

-

The heat exchanger is cold

-

Draft hasn’t established yet

-

Gas pressure hasn’t normalized

-

The cabinet hasn’t heat-soaked

-

Airflow hasn’t hidden mistakes

Jake watches that moment because it’s unfiltered truth.

“If the flame struggles cold, it’ll fail hot later. It’s just waiting for the right conditions.”

🔍 What Jake Watches Before the Blower Ever Starts

Most people look after airflow.

Jake looks before airflow can save anything.

Jake’s eyes go to four places immediately:

-

Ignition timing

-

Flame shape

-

Flame color

-

Flame stability

Each one tells a different story.

⏱️ Ignition Timing: Fast Isn’t Always Healthy

A fast ignition looks good to homeowners.

It doesn’t impress Jake.

What Jake wants:

-

Smooth ignition

-

No hesitation

-

No violent “pop”

-

No delayed catch

What Jake flags immediately:

-

Delayed ignition → gas pooling risk

-

Hard ignition → pressure or igniter positioning issues

-

Uneven light-off → burner alignment or debris

A furnace that lights too aggressively is often compensating for something wrong upstream.

🔺 Flame Shape: Geometry Matters More Than Color

Most techs obsess over color.

Jake starts with shape.

A correct startup flame should be:

-

Even across all burners

-

Tight to the burner ports

-

Pulled gently inward toward the heat exchanger

-

Consistent from burner to burner

Jake gets concerned when he sees:

-

One burner lagging behind the others

-

Flame lifting off the ports

-

Flame rolling sideways

-

Flame pushing outward instead of pulling in

That last one is critical.

“Flame should chase draft — not fight it.”

Outward push usually means draft or pressure imbalance, not a bad furnace.

🎨 Flame Color: Blue Is the Baseline, Not the Verdict

Yes — blue is good.

But blue alone doesn’t mean correct combustion.

Jake looks beyond “blue”:

-

Is it deep blue or washed-out?

-

Is there yellow tipping at startup?

-

Does the color stabilize quickly or wander?

-

Does it change after 10–15 seconds?

Yellow at startup can indicate:

-

Incomplete combustion

-

Poor draft establishment

-

Gas pressure mismatch

-

Contaminants in the burner area

Temporary yellow that cleans up quickly can be normal.

Persistent yellow is never ignored.

Jake doesn’t wait for soot to prove a point.

🌪️ Flame Movement: Stability Predicts Longevity

The most important question Jake asks:

Does the flame look confident — or nervous?

A healthy startup flame:

-

Moves smoothly

-

Reacts gently to cabinet airflow

-

Doesn’t flutter or dance

-

Remains anchored

An unstable flame:

-

Flickers rapidly

-

Pulls away from ports

-

Wavers when nearby doors close

-

Changes behavior as draft builds

Unstable flame today becomes:

-

Flame sensor issues tomorrow

-

Lockouts next season

-

Heat exchanger stress long-term

🧱 The GR9S Burner Design: Why Startup Behavior Matters More Here

The Goodman GR9S800803BN uses a proven single-stage burner system — simple, reliable, but honest.

That simplicity means:

-

It doesn’t hide mistakes

-

It doesn’t self-correct poor setup

-

Startup conditions matter more than modulation

If gas pressure, draft, or burner alignment is off, the GR9S shows it immediately.

That’s a feature — not a flaw.

📏 Gas Pressure: Why Jake Doesn’t Trust the Sticker

Manufacturer specs matter.

Real-world conditions matter more.

Jake checks pressure before and after startup because:

-

Static pressure lies

-

Supply pressure changes under load

-

Regulators behave differently when cold

Improper pressure often shows up as:

-

Delayed ignition

-

Flame lift

-

Color inconsistency

Jake verifies against Goodman’s specs and confirms under actual firing conditions

(Goodman Gas Furnace Technical Data.

🌬️ Draft Before Comfort: Why Venting Shows Its Hand Immediately

Draft problems rarely wait.

On first flame, Jake watches:

-

Flame pull direction

-

Stability before blower start

-

Reaction when cabinet doors are removed

Poor draft shows up as:

-

Lazy flame

-

Flame rollout tendency

-

Delayed stabilization

These issues often trace back to:

-

Vent sizing errors

-

Chimney restrictions

-

Improper rise or termination

Jake references NFPA venting guidance, not guesswork

(NFPA 54 – National Fuel Gas Code).

🧪 Combustion Analysis vs. Combustion Observation

Jake uses instruments — but eyes come first.

A combustion analyzer confirms numbers.

The flame tells the story before numbers stabilize.

That’s why Jake:

-

Observes first

-

Measures second

-

Adjusts last

For reference values, Jake aligns with industry combustion standards

(ACHR News – Combustion Analysis Basics).

🧠 Why Thermostat Cycling Can Hide Startup Problems

Once the thermostat cycles:

-

Draft is established

-

Heat exchanger is warm

-

Blower airflow stabilizes flame

-

Cabinet pressure equalizes

Problems disappear — temporarily.

That’s why Jake reads flame before:

-

Comfort improves

-

Noise settles

-

Airflow masks imbalance

“If it only looks good after five minutes, it wasn’t good to begin with.”

📝 What Jake Documents After the First Flame

Before leaving, Jake records:

-

Ignition timing observations

-

Flame shape notes

-

Color behavior at startup

-

Any adjustments made

This protects:

-

The installer

-

The homeowner

-

The equipment

It also prevents finger-pointing later.

🚫 The Three Flame Mistakes Jake Sees Most Often

❌ Mistake #1: Ignoring minor instability

Small problems grow.

❌ Mistake #2: Assuming airflow fixes everything

Airflow hides — it doesn’t heal.

❌ Mistake #3: Trusting factory settings blindly

Every house is different.

🔚 Final Word from Jake

The furnace speaks before it heats.

That first flame doesn’t care about reviews, warranties, or brand loyalty.

It only reflects how well the system was actually started.

Read it correctly, and you prevent:

-

Callbacks

-

Lockouts

-

Premature failures

-

Heat exchanger stress

Ignore it, and the furnace remembers — even if you don’t.

“The thermostat doesn’t tell the truth.

The flame does.”

🔗 External References

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Static Pressure on Minute One: Why Jake Measures Airflow Before Heat Soaks the Cabinet