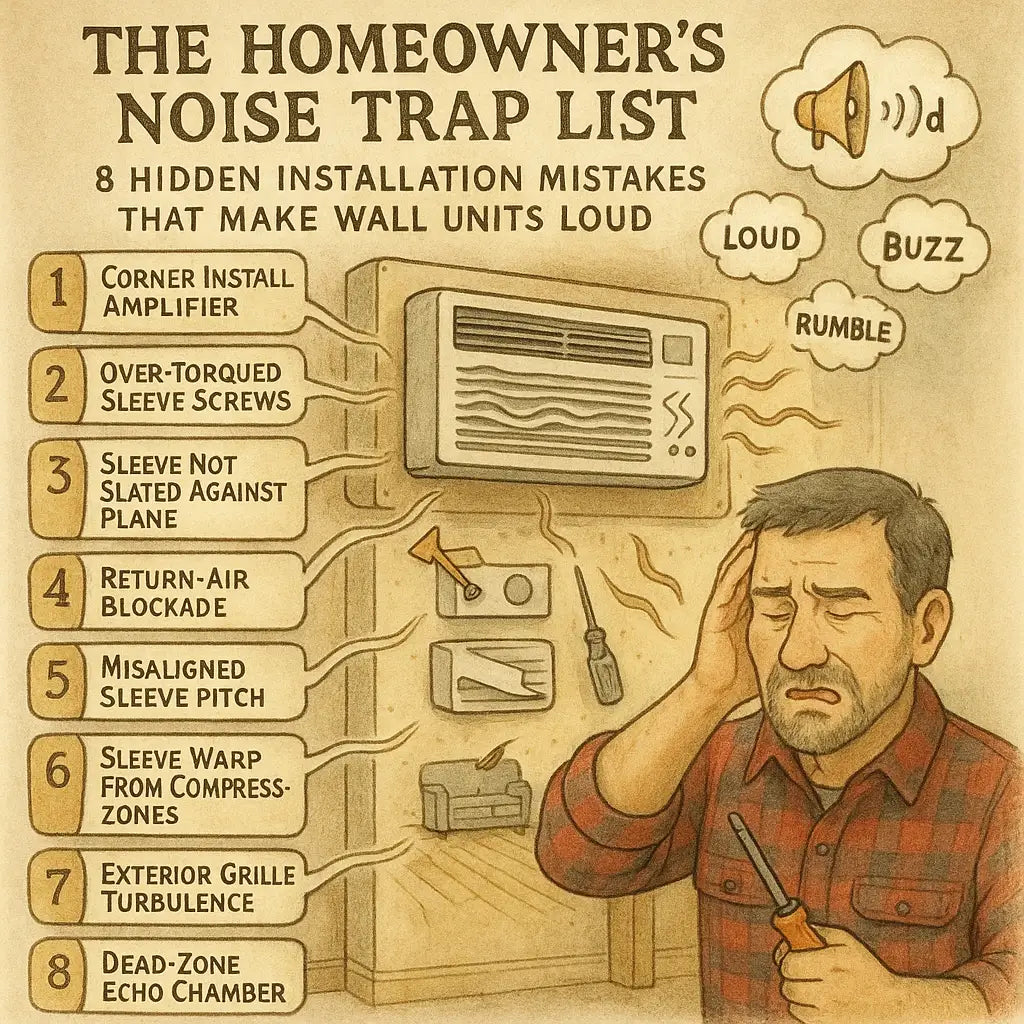

Why a through-the-wall AC gets noisy — and why it’s almost never the machine’s fault.

When a homeowner installs an Amana PBE123J35AA (or any through-the-wall AC/heat unit), they expect cool air, warm nights, and quiet comfort.

But many end up asking:

-

“Why does my unit hum so loudly?”

-

“Why is it rattling?”

-

“Why does it vibrate the whole wall?”

-

“Why does the tone change when the compressor kicks on?”

-

“Why is it louder than my old one?”

Mike has fixed thousands of “loud” installs across old homes, new construction, and everything in between.

After decades of service calls, he discovered something surprising:

90% of noise issues are caused by installation mistakes — not the AC itself.

These mistakes are subtle.

They hide behind drywall, trim, shims, bolt patterns, airflow paths, and even room geometry.

Mike calls them Noise Traps —

silent mistakes that turn a good installation into a noisy one.

This guide explains each of the 8 traps, why they happen, and how Mike fixes them.

📚 SECTION 1 — Why Wall Units Become Loud

Icon: 🔍

Through-the-wall units produce predictable mechanical sounds:

-

Compressor hum

-

Fan movement

-

Airflow noise

-

Expansion/contraction clicks

These are normal.

But installation problems amplify them into:

-

Vibrations

-

Rattles

-

Resonance

-

Echoing

-

Buzzing

-

Drumming

-

Low-frequency pulsing

Mike compares it to placing a speaker in a cardboard box:

“The AC isn’t loud.

What you mounted it in is loud.”

This is why homeowners need to know the 8 Noise Traps.

🎧 SECTION 2 — Noise Trap #1: The Corner Install Amplifier

Icon: 📐

Corners create natural echo chambers.

When a unit is installed too close to a corner (within 18 inches):

-

Airflow collides with two surfaces

-

Sound waves bounce and double back

-

Vibrations resonate through the perpendicular framing

-

The return air becomes turbulent

-

Pressure at the inlet rises, causing fan strain

Mike says:

“A corner-mounted wall unit is a megaphone pointed at the living room.”

Why it happens:

Homeowners assume corner space is “free wall space.”

Fix:

Move sleeve opening at least 18–24 inches away from the corner

or add Mike’s corner sound-break shims to decouple the frame.

🔧 SECTION 3 — Noise Trap #2: Over-Torqued Sleeve Screws

Icon: 🔩

This is the most common noise trap — and the least understood.

Homeowners overtighten fasteners because they believe “tighter is better.”

The result?

-

Sleeve warps

-

Metal flexes

-

Resonance nodes appear

-

Compressor vibrations amplify

-

Low-frequency humming spreads through wall cavities

Mike explains:

“An overtightened screw turns your sleeve into a tension drum.”

Why it happens:

DIY installers assume the sleeve must be locked immovably in place.

Fix:

Use Mike’s Quiet-Home Bolt Pattern and torque screws only ¼ turn past snug.

🧱 SECTION 4 — Noise Trap #3: Sleeve Not Seated Against a True Plane

Icon: 📏

Walls are rarely flat.

Studs bow.

Drywall curves.

Insulation bulges.

If the sleeve is fastened against an uneven plane:

-

One part of the frame floats

-

Another part is compressed

-

Vibration pathways form

-

AC chassis rattles during compressor cycles

This leads to:

-

A loud humming

-

Intermittent buzzing

-

A hollow drumming sound

Mike checks sleeve seating using:

-

A 4-foot straightedge

-

A laser line

-

A compression-zone map

Why it happens:

Installers trust the drywall instead of the wall’s true geometry.

Fix:

Shim strategically until the sleeve rests against three contact planes, not one warped point.

🌬️ SECTION 5 — Noise Trap #4: The Return-Air Blockade

Icon: 🌀

Any obstruction near the return grille increases noise:

-

Sofas

-

Curtains

-

Dressers

-

Beds

-

Corners

-

Plants

-

Cabinets

-

TV stands

When return air is blocked:

-

Fan suction increases

-

Airflow speed increases

-

Turbulence rises

-

Motor noise jumps

-

The unit sounds like it’s “working too hard”

Mike says:

“Most noisy units aren't loud — they’re suffocating.”

Why it happens:

Homeowners prioritize room aesthetics over airflow paths.

Fix:

Apply the Return-Air Guardrail:

36" open space in front of unit, 12–18" on sides.

🛠️ SECTION 6 — Noise Trap #5: Misaligned Sleeve Pitch

Icon: 📐📉

If the sleeve’s drainage slope is incorrect — either too steep, too flat, or uneven:

-

Compressor shifts position

-

Condensate splashes

-

Fan blades skim water

-

Coil airflow becomes imbalanced

-

Drip pan resonance becomes audible

Noise types caused by incorrect slope:

-

Splashing

-

Dripping

-

Metallic humming

-

Low-frequency rumble

-

“Gurgle-hum” on humid days

Mike uses his 3-Point Drainage Slope Formula to prevent:

-

Midline dips

-

Reverse slope

-

Corner pooling

Why it happens:

Installers eyeball the pitch.

Fix:

Measure slope precisely: ¼" drop per 14–16" of sleeve depth.

📦 SECTION 7 — Noise Trap #6: Sleeve Warp From Compression Zones

Icon: 🧩

Walls contain hidden compression zones from:

-

Insulation pressure

-

Framing twist

-

Sheathing irregularities

-

Drywall screw depth differences

If the sleeve presses unevenly against one or more of these zones:

-

A bow forms

-

AC chassis sits unevenly

-

Internal components vibrate louder

-

The unit “thumps” when compressor starts

Mike maps compression zones before seating the sleeve.

Why it happens:

Installers force the sleeve into the wall instead of adjusting the wall to the sleeve.

Fix:

Use plastic shims to neutralize compression points and create a stable sleeve cradle.

🔉 SECTION 8 — Noise Trap #7: Exterior Grille Turbulence

Icon: 🌬️📢

The exterior grille interacts with wind and airflow.

Problems include:

-

Loose grilles

-

Missing screws

-

Incorrect gasket pressure

-

Air turbulence hitting siding

-

Wind-induced resonance

-

Leaves or debris vibrating against grille

Symptoms:

-

Whistling

-

Fluttering

-

Rattle during windy days

-

“Helicopter” noise when wind gusts hit

Mike checks:

-

Exterior screw torque

-

Grille seal compression

-

Airflow clearance

-

Weather Lock integrity

Why it happens:

Homeowners assume the noise comes from inside, not outside.

Fix:

Reinforce exterior grille, add neoprene washers, and use proper airflow-direction grille screws.

🎶 SECTION 9 — Noise Trap #8: The Dead-Zone Echo Chamber

Icon: 🕳️

Rooms with poor acoustics amplify sound naturally:

-

Smooth floors

-

Parallel walls

-

Hard surfaces

-

Uninsulated interior walls

-

High ceilings

-

Bare rooms with no soft materials

The AC’s normal operational noise becomes exaggerated.

This is worst in:

-

Home offices

-

Converted bonus rooms

-

Nursery rooms

-

Finished basements

-

Sunrooms

Mike calls this a “dead-zone echo chamber.”

Why it happens:

Nothing in the room absorbs noise.

Fix:

Add soft surfaces or install Mike’s Return-Air Guardrail to restore flow balance.

Even small additions help:

-

Rugs

-

Curtains (not blocking return air)

-

Plants

-

Wall art

-

Upholstered furniture

🧬 SECTION 10 — Why Noise Traps Affect the Amana PBE123J35AA So Strongly

Icon: 🧊

Modern through-the-wall units are engineered for:

-

Tight tolerances

-

Balanced airflow

-

Precisely calibrated fan blades

-

Specific vibration thresholds

When the installation environment is wrong:

-

Sound pathways multiply

-

Vibrations intensify

-

Pressure differentials increase

-

Fan motors strain

The PBE123J35AA is quiet when installed correctly.

Noise appears only when a Noise Trap interferes with airflow or mounting geometry.

🧰 SECTION 11 — Mike’s 6-Step Quiet-Home Diagnostic

Icon: 🔎

When Mike arrives at a “noisy AC” call, he doesn’t touch the unit first.

He checks:

-

Return-air clearance

-

Corner offset

-

Sleeve torque pattern

-

Drain slope

-

Midline compression

-

Exterior grille airflow

He solves 80% of noise complaints without ever opening the AC chassis.

🏠 SECTION 12 — How to Build a “Noise-Proof” Wall Unit Installation

Icon: 🛡️

Combine these:

✔ Quiet-Home Bolt Pattern

Controls sleeve tension.

✔ Two-Plane Sleeve Alignment

Prevents torsion hum.

✔ Compression Zone Mapping

Stops sleeve warping.

✔ 3-Point Drainage Slope

Prevents drip noise and compressor pitch distortion.

✔ Return-Air Guardrail

Ensures smooth airflow.

✔ Weather Lock Strategy

Reduces exterior turbulence.

When all six are used together, the system becomes whisper-quiet.

🔗 SECTION 13 — Verified External References

These links support best practices Mike uses:

-

Building Science Corporation – Wall Moisture & Cavity Pressure

https://www.buildingscience.com/ -

U.S. Department of Energy – Moisture Management & Wall Integrity

https://www.energy.gov/ -

NFPA – Electrical Requirements for Room Air Conditioners

https://www.nfpa.org/ -

Family Handyman – Understanding Stud Walls & Hidden Utilities

https://www.familyhandyman.com/ -

HUD Residential Construction Guide – Structural Load Path Basics

https://www.huduser.gov/ -

EPA Indoor Moisture & Ventilation Guide

https://www.epa.gov/

🏁 Conclusion — Loud Units Aren’t Bad Units. They’re Bad Installs.

Mike’s Noise Trap List proves one thing:

The AC isn’t the problem.

The installation is the amplifier.

By avoiding the 8 Noise Traps, a wall unit like the Amana PBE123J35AA becomes:

-

Quiet

-

Smooth

-

Efficient

-

Comfortable

-

Predictable

-

Long-lasting

Homeowners often spend years tolerating a loud AC…

when the fix takes only 30–60 minutes using Mike’s installation rules.

Buy this on Amazon at: https://amzn.to/47M5ozS

In the next topic we will know more about: The Structural Reality Check: Mike’s 12-Minute Pre-Install Inspection That Saves Homeowners Thousands