🌿 Introduction: Copper Is the Quiet Soul of Every Eco-Efficient HVAC System

Most homeowners think refrigerant determines cooling performance. Some think the outdoor condenser is the star. Others point to SEER2 ratings or the thermostat. But here’s what Savvy — and every high-end installer — knows:

The quality of your copper line set determines whether your system performs like a sustainability champion… or a leaky, high-pressure headache.

Whether you're installing a high-efficiency R-32 system or a legacy R-410A unit, the copper line set is the bloodstream of the HVAC ecosystem. And just like your body, any kink, restriction, contamination, or micro-crack can throw the entire system out of equilibrium.

This guide explores the hidden geometry, physics, and craftsmanship behind bending copper, forming perfect flares, brazing clean joints, and preventing leaks that waste refrigerant — and accelerate climate impact.

If you want your system to whisper, chill, and last 20+ years, this is the Savvy way.

🔧 1. Why Copper Matters — The Sustainability Science Behind Line Sets

Icon: 🧬

Copper isn’t just convenient. It’s thermodynamically magical.

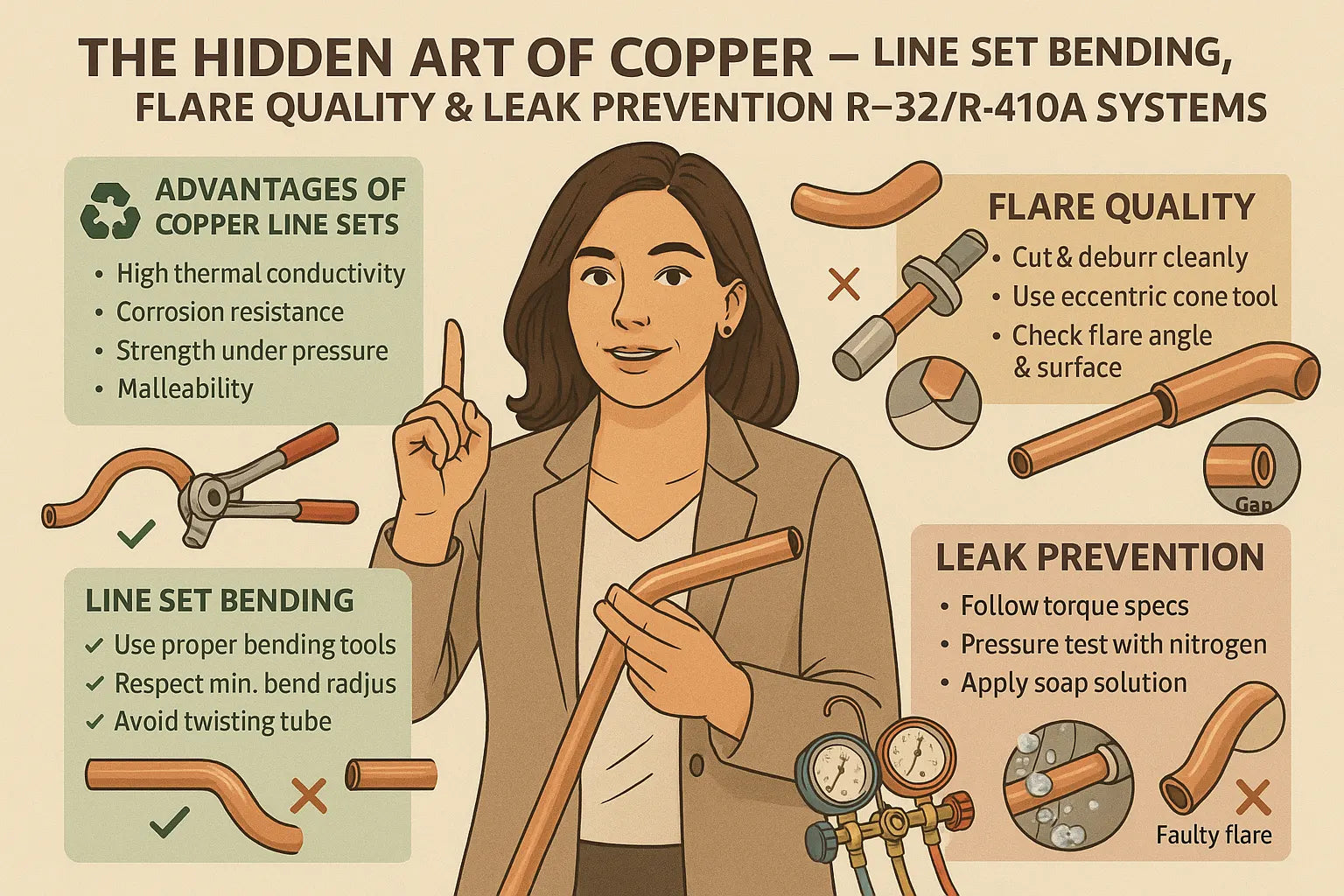

✨ Why Copper Is Essential in R-32 & R-410A Systems

-

Excellent thermal conductivity

-

High resistance to corrosion

-

Strong enough to handle high pressures

-

Malleable for tight-radius bending

-

Easy to join with flares or brazing

-

Naturally antimicrobial (air quality bonus!)

🌍 Refrigerant Pressure Reality

-

R-410A operates at ~50–70% higher pressures than older R-22 systems.

-

R-32 operates at similar pressures but with superior heat transfer.

High pressure = zero forgiveness for bad line set work.

Kink it? You restrict refrigerant flow.

Overheat it? You anneal copper and weaken the walls.

Flare it poorly? You create a leak path.

Contaminate it? You destroy the compressor.

Copper work is sustainability work.

🔄 2. Choosing the Right Line Set — Don’t Let Cheap Materials Sabotage Your System

Icon: 🧲

A standard line set includes:

-

Liquid line (1/4” or 3/8”)

-

Suction line (1/2”, 5/8”, or 3/4”) — insulated

-

Flare nuts (for mini splits)

-

Insulation (⅜–¾” wall thickness recommended for R-32)

💡 Savvy’s Rules for Choosing Copper

-

Thicker insulation = better thermal retention.

-

Straight copper is better than coiled copper for long runs.

-

Always match manufacturer suction line diameter.

-

Never reuse old line sets for new refrigerants.

-

Avoid low-cost line sets with poor annealing consistency.

Verified Resource

ACCA Refrigerant Line Guidelines

🔗 https://www.acca.org

🌀 3. The Art of Bending Copper — Geometry That Saves Efficiency

Icon: ➿

Copper bends beautifully… until it doesn’t.

A poorly executed bend will:

-

Restrict refrigerant flow

-

Increase system noise

-

Raise superheat

-

Stress the compressor

-

Reduce SEER2 performance

-

Cause oil return issues

🎨 Savvy’s 5 Principles of Copper Bending

1. Use the Right Bender for the Job

-

For 1/4”–3/8”: spring benders or lever benders

-

For 1/2” and above: heavy-duty mandrel or ratcheting benders

Never use your hands alone. Kinks are system killers.

2. Respect the Minimum Bend Radius

Every manufacturer specifies a minimum radius (usually ≥ 5x the tubing diameter).

Tighter bends = turbulence + pressure drop.

3. Keep Bends Smooth and Continuous

Multiple small bends create:

-

Hot spots

-

Velocity changes

-

Hairline copper fatigue

Strive for single, sweeping arcs.

4. Don’t Twist the Tubing

Twisting changes the internal diameter and stresses the copper grain structure.

Keep it planar.

5. Bend Before Insulating

Trying to bend insulated copper will:

-

Pinch insulation

-

Tear foam

-

Create condensation points

🛠️ Pro Tip

After each bend, look through the copper like a telescope.

If the circle isn’t round, you’ve created a restriction.

🔩 4. Flare Quality — Where Even 1 Grain of Dust Can Ruin a $5,000 System

Icon: 🔍

Mini splits and many R-32 systems rely heavily on flared connections instead of brazed joints.

A flare is a gasketless, metal-on-metal seal.

Perfect = long life. Imperfect = slow leak.

🍃 Why R-32 Makes Flare Precision More Important

R-32 is:

-

More efficient

-

Lower GWP

-

Higher pressure

-

More prone to leak through imperfect flare seats

🔧 Savvy’s Step-by-Step for the Perfect Flare

🔹 Step 1 — Cut Cleanly, Without Crushing

Use a tubing cutter.

Rotate gently.

Don’t overtighten — this ovalizes the tube.

🔹 Step 2 — Deburr Inside and Outside

Use an internal reamer.

Aim downward so shavings fall out, not in.

1 shaving = clogged metering device = efficiency collapse.

🔹 Step 3 — Slide the Flare Nut on First

Everyone forgets once.

Never forget twice.

🔹 Step 4 — Use a High-Quality Eccentric Flare Tool

The eccentric cone “walks” the flare outward, creating:

-

Uniform thickness

-

Smooth surface

-

Strong mechanical structure

Avoid cheap symmetrical cone flare tools — they cause concentric cracking.

🔹 Step 5 — Inspect the Flare Like a Jeweler

Look for:

-

Even shine

-

No radial cracks

-

No burrs

-

45-degree angle

-

Smooth chamfer

🔹 Step 6 — Torque to Manufacturer Specs

Under-torqued = leaks

Over-torqued = micro-cracks

Always use a calibrated torque wrench.

🔹 Step 7 — Refrigerant Oil on the Back of the Flare

Not the sealing surface — only the threads.

This reduces galling and ensures proper seating.

🔥 5. Brazing for R-410A/R-32 — Clean, Oxygen-Free, and Beautiful

Icon: 🛠️

For systems requiring brazing (often furnaces + coils, heat pumps, and some R-32 condensers), quality is everything.

🌡️ Why Brazing Quality Matters

Bad brazing leads to:

-

Oxidation flakes

-

Acid formation

-

Capillary tube blockage

-

Compressor failure

-

Leaks

🔥 Savvy’s Brazing Rules

Rule #1 — Always Purge with Nitrogen

Flow rate: 1–3 SCFH (just a whisper)

This prevents oxidation (“scale”) forming inside the pipe.

Rule #2 — Use the Right Rod

-

Sil-phos 15% for copper-to-copper

-

Silver alloy for copper-to-brass

Rule #3 — Don’t Overheat the Copper

Red-hot copper = annealed copper = weakened structural integrity.

Use heat control and back-and-forth sweeping motion.

Rule #4 — Cool Naturally

Never quench with water or air blast — creates micro-fractures.

Verified Resource

ASHRAE Brazing Standards

🔗 https://www.ashrae.org

🧪 6. Leak Prevention — Because Every Gram of Refrigerant Matters

Icon: 🧯

Refrigerant leaks are devastating:

-

Financially

-

Environmentally

-

Mechanically

Even “tiny” leaks cause:

-

Higher energy use

-

Oil migration

-

Poor cooling performance

-

Compressor overheating

-

Refrigerant release into the atmosphere

🌍 R-32 Climate Impact

R-410A GWP: 2088

R-32 GWP: 675

Still harmful — but dramatically better.

Reducing leaks makes the system climate-safer.

✔️ Savvy’s Leak Prevention Checklist

1. Pressure Test with Nitrogen

Pressurize up to:

-

350–450 psi for R-410A

-

450–550 psi for R-32 (follow manufacturer limits)

Hold for 24 hours if possible.

2. Use Bubble Solution on All Joints

Electronic sniffers are great,

but soap never lies.

3. Perform a Deep Vacuum (Triple Evacuation Method)

Target:

≤ 300 microns (ideal)

≤ 500 microns (acceptable)

Moisture inside the system becomes acid.

Acid eats compressors for breakfast.

4. Confirm Micron Level Holds

If the vacuum rises rapidly, you have:

-

A leak

-

Moisture

-

A loose valve

Fix before charging.

5. Record All Readings

Real pros document everything.

Verified Resource

EPA Refrigerant Handling Standards

🔗 https://www.epa.gov/section608

🧊 7. Oil Return & Line Set Slope — The Silent Lifespan Extender

Icon: 🛢️

Refrigerant isn’t alone in the copper tubing.

The compressor sends oil circulating with it — and that oil must return.

💡 Savvy’s Rules for Proper Oil Return

-

Keep long vertical risers ≤ 20 ft unless oil traps are used.

-

Provide oil traps every 20 ft of rise.

-

Maintain a consistent slope on horizontal runs.

-

Avoid low spots where oil pools.

Poor oil return = compressor death.

🧼 8. Cleanliness Standards — The Part No One Talks About (But Savvy Obsesses Over)

Icon: ✨

In R-32/R-410A systems, the margin for contamination is tiny.

🚫 Contaminants That Kill Systems

-

Copper shavings

-

Moisture

-

Burner soot

-

Brazing scale

-

Dust and pollen

-

Old compressor oil

✔️ Savvy Cleanliness Ritual

-

Cap every line end immediately after cutting.

-

Blow nitrogen through before sealing.

-

Keep flare tools spotless.

-

Never drag copper tubing on the ground.

-

Purge nitrogen while brazing.

The cleanest installs outperform sloppy ones by years.

🌡️ 9. Insulation Quality — Comfort, Efficiency & Condensation Control

Icon: 🧊

A perfectly bent, beautifully flared line set can still fail if insulation is poor.

✔️ Savvy Insulation Standards

-

Thick (¾") insulation for R-32 suction lines

-

Vapor-sealed joints using UV-rated tape

-

Insulation sleeves for fittings

-

Avoid gaps, tears, or compression

-

Consider armaflex glue for humid climates

Poor insulation = dripping moisture + mold + efficiency losses.

Verified Resource

Building Science Corporation – Moisture Guidelines

🔗 https://buildingscience.com

🧭 10. Routing Line Sets the Savvy Way — Longevity in Every Curve

Icon: 🗺️

A line set should be:

-

Protected

-

Straight

-

Accessible

-

Quiet

-

Rise/fall optimized

-

Thermally isolated

❌ Avoid:

-

Tight 90° corners

-

Sun exposure

-

Locations prone to vibration

-

Running close to furnace flue pipes

-

Unsupported spans

✔️ Do:

-

Use line set covers

-

Provide isolation pads where pipes cross studs

-

Strap every 4–6 ft

-

Use rubber grommets for wall penetrations

This reduces noise and extends system life.

🌍 11. Sustainability Wins When Copper Work Is Done Right

Perfectly installed line sets deliver:

🌱 Environmental Benefits

-

Fewer refrigerant leaks

-

Lower energy consumption

-

Reduced compressor cycling

-

Longer equipment lifespan

-

Lower global warming impact

🏡 Homeowner Comfort Benefits

-

Faster cooling

-

Quieter operation

-

Better humidity control

-

Stable temperatures

-

Higher real-world SEER2 performance

⚙️ Mechanical Benefits

-

Proper superheat/subcool

-

Better oil return

-

Lower head pressure

-

Less compressor strain

Copper craftsmanship is the most underrated green technology in HVAC.

🌟 Closing: Copper Is Art, Physics, and Climate Responsibility

In the world of HVAC, copper line sets are the quiet heroes. When you bend them correctly, flare them perfectly, braze them cleanly, and install them thoughtfully, you create a system that:

-

Runs quieter

-

Uses less energy

-

Lasts longer

-

Leaks less

-

Delivers higher comfort

-

Reduces carbon impact

This is not just installation.

This is craftsmanship with a climate conscience.

This is the hidden art of copper — Savvy style.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: Landing Pad Logic — How to Build a Vibration-Free, Noise-Reducting Base for Your Goodman Condenser