🌿 Introduction: A Quiet System Starts at the Ground, Not the Equipment

Homeowners often assume noise comes from the condenser fan, the compressor, or loose panels. But Savvy knows the truth:

Noise begins at the base.

And so does vibration.

And so does long-term efficiency.

If your Goodman condenser — whether it’s the 3-ton GLXS4BA3610 or a similar model — sits on a poorly engineered pad, you’re guaranteed:

-

Excess vibration

-

Louder operation

-

Misaligned refrigerant lines

-

Premature copper fatigue

-

Settling and tilting

-

Increased compressor workload

-

Lower SEER2 performance

A condenser is only as stable as the surface beneath it.

A whisper-quiet, high-efficiency system requires a vibration-smart foundation.

This is Landing Pad Logic — Savvy-style.

🧱 1. Why Condenser Pads Matter — The Physics Behind Quiet HVAC

Icon: ⚙️

Your outdoor unit contains components that generate vibration:

-

Compressor: The main source

-

Fan motor: Secondary source

-

Refrigerant flow: Especially at high startup torque

-

Wind resonance: External force

When these vibrations transfer into:

-

The ground

-

The structure

-

The copper line set

-

The wall penetrations

They amplify noise, reduce mechanical stability, and introduce wear points.

🌀 How a Bad Landing Pad Affects System Performance

-

Tilted condensers cause oil migration issues

-

Vibration wears out electrical connections

-

Excess movement stresses line sets

-

Uneven weight distribution increases compressor strain

-

Noise echoes into living spaces

-

Pad movement can break condensate drainage paths

A high-efficiency Goodman condenser deserves a high-efficiency foundation.

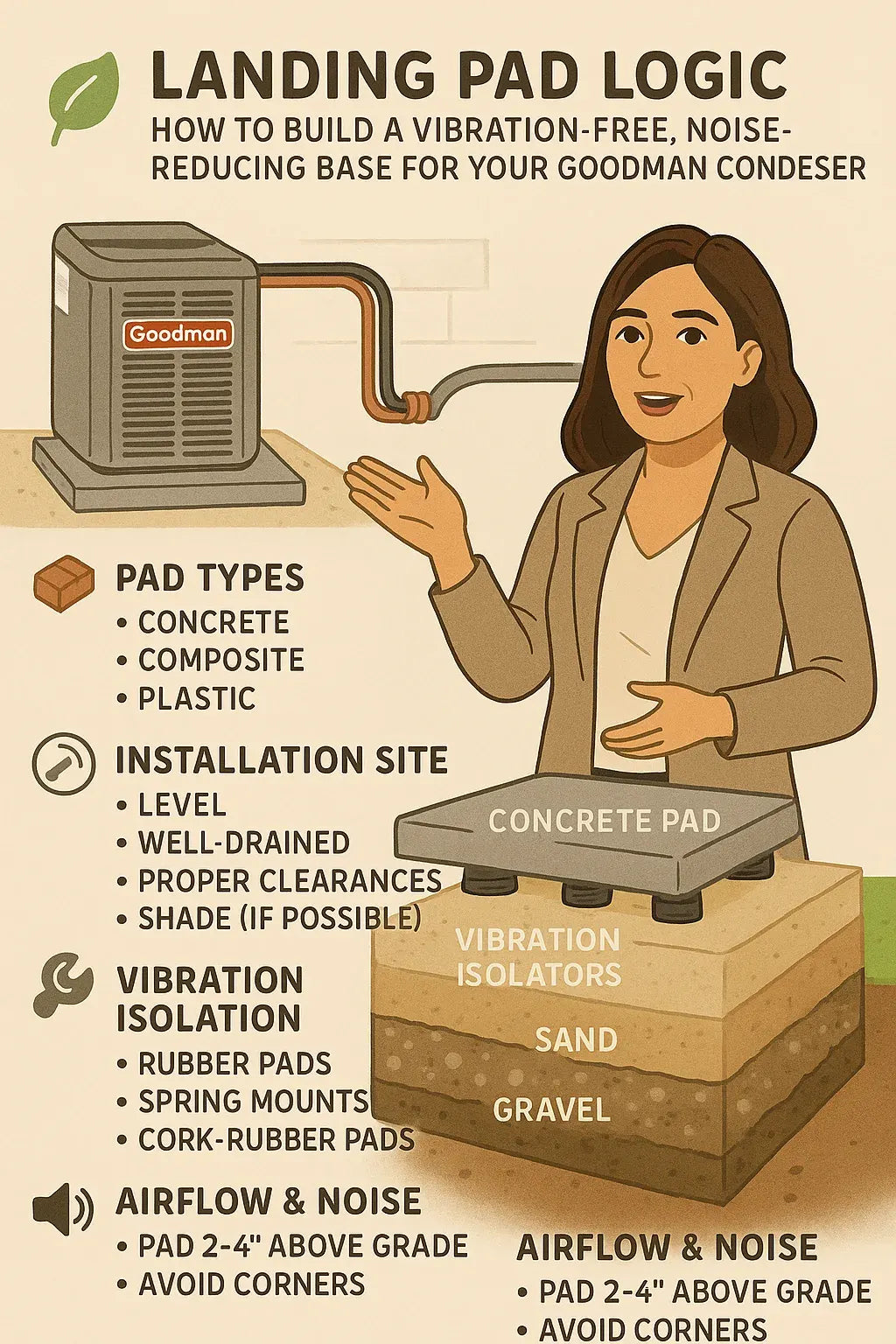

🧊 2. Pad Types — Which Base Belongs Under a Goodman System?

Icon: 🧱

Not all pads are created equal. Savvy breaks them down:

1. Lightweight Plastic Pads (Easiest, but Not the Best)

Pros:

-

Easy to transport

-

UV resistant

-

Affordable

Cons:

-

Transfer vibration

-

Can warp in sun

-

May settle unevenly

-

Not ideal for 3-ton+ units

2. Composite Condenser Pads (Savvy’s Mid-Range Choice)

Pros:

-

Lightweight but strong

-

Good vibration absorption

-

Weather resistant

-

Stable for most 2–5 ton systems

Cons:

-

Must be installed on level soil

-

Can still transmit vibration if not isolated

3. Concrete Pads (The Gold Standard for Stability)

Pros:

-

Extremely stable

-

Best long-term durability

-

Excellent vibration dampening

-

Ideal for hot climates

Cons:

-

Heavy

-

Requires proper grading

-

Can crack if soil shifts

4. Elevated Stands (For Flood Zones or Heavy Snow Areas)

Pros:

-

Prevents snow/flood damage

-

Provides airflow beneath the unit

-

Reduces pest infiltration

Cons:

-

MUST have vibration isolators

-

Improper installation becomes noisy

-

Requires strong anchoring

Savvy’s Preferred Setup:

Concrete pad + rubber vibration isolators + perfectly leveled aggregate base.

This creates a quiet, stable, long-life foundation.

🔍 3. Soil & Groundwork — The Step Most Installers Ignore

Icon: 🌎

Before the pad touches the ground, the earth must be prepared for decades of stability.

Step 1 — Choose the Location Wisely

A condenser should be placed:

-

12–24 inches away from the wall

-

In a shaded area when possible

-

Away from bedrooms

-

On the downwind side of the house

-

With unobstructed airflow (18–24 inches clearance on all sides)

Step 2 — Remove Organic Material

Grass, roots, topsoil, and mulch all decompose and shift.

Savvy removes at least 4–6 inches of organic matter before starting the base.

Step 3 — Install a Compacted Gravel Base

Use:

-

¾” crushed stone

-

2–4 inches deep

-

Compact it with a tamper

-

Create a perfectly level surface

Compaction prevents:

-

Settling

-

Tilting

-

Rock shifting

-

Water pooling

This is where long-term quiet operation begins.

Step 4 — Add a Sand Layer for Micro-Leveling

A thin ½–1 inch layer of sand smooths the imperfections.

Sand + gravel = a self-adjusting foundation under load.

🛋️ 4. Setting the Pad — Precision Makes Perfect

Icon: 📐

The pad must be:

-

Level

-

Stable

-

Uniformly supported

-

Not directly touching soil

✔️ Savvy’s Pad-Setting Rules

Rule 1: Use a 4-Foot Level

Short levels lie.

Use a long level for accuracy across surface area.

Rule 2: Slight Rearward Pitch (Optional)

Some installers add a 1° tilt away from the house to encourage:

-

Water drainage

-

Snowmelt flow

-

Reduction of puddle-freezing under the unit

Rule 3: Confirm No “Rocking”

Press down on all corners.

If it moves, relevel the base.

Rule 4: Pad Should Be Bigger Than the Condenser

Most 3-ton Goodman units work best with:

-

32×32 inch pad minimum

-

36×36 inch preferred

This reduces edge load stress.

🔇 5. Vibration Isolation — The Heart of Noise Reduction

Icon: 🔧

Condenser vibration is natural.

Condenser noise is optional.

Adding vibration isolation transforms performance.

Option 1 — Rubber Vibration Pads (Savvy-Approved)

Place between condenser feet and the pad.

Benefits:

-

Reduces structure-borne noise

-

Eliminates “buzzing” sounds

-

Increases compressor lifespan

Option 2 — Spring Mounts (For Elevated Stands or Metal Frames)

Best for:

-

Roof installations

-

Multi-unit platforms

-

High vibration zones

Springs decouple the system from the structure — dramatically reducing noise.

Option 3 — Cork-and-Rubber Hybrid Pads

Used in commercial HVAC.

Adds:

-

Extra sound dampening

-

Greater durability

-

Less compression over time

Savvy’s 4 Isolation Rules

-

Never let metal feet touch the pad directly.

-

Tighten bolts only to manufacturer torque specs.

-

Do not overtighten or “pinch” isolation pads.

-

Re-check isolators after system startup.

🔥 6. Condenser Mounting & Anchoring — Safety Meets Quiet Operation

Icon: 🛠️

Improper anchoring = vibration amplifier.

✔️ Use Anti-Vibration Bolts

These allow small flex movements without transferring noise.

✔️ Avoid Hard Metal-to-Pad Contact

Use neoprene washers between metal fasteners.

✔️ In Hurricane Zones

Strap the condenser using:

-

Approved hurricane tie-down kits

-

Stainless hardware

-

Elevated pad if required

✔️ For Stand Installations

Ensure:

-

Rubber isolators under each leg

-

Cross-bracing for stability

-

Uniform load distribution

🌬️ 7. Airflow, Noise & Pad Height — The Triangle of Quiet Comfort

Icon: 🌀

The pad height affects airflow, snow exposure, and noise reflection.

Higher Pad = Better Airflow but More Exposure

Good for:

-

Snow-prone areas

-

Dense vegetation zones

-

Low airflow locations

Lower Pad = Quieter Operation

Ground-level pads reduce the “echo chamber” effect between wall and condenser.

Savvy’s Rule of Thumb:

Pad height of 2–4 inches above grade for the quietest operation unless snow or flood risk requires elevation.

🔧 8. Line Set Support — Protecting Copper from Vibration Fatigue

Icon: 🔩

Copper line sets transmit vibration into the home.

A high-quality pad reduces this, but line set supports finalize the noise control.

✔️ Use Line Set Clamps with Rubber Inserts

They:

-

Absorb vibration

-

Prevent copper-on-metal contact

-

Reduce “ticking” noises

-

Extend copper lifespan

✔️ Avoid Sharp Bends Near the Condenser

Tight radius bends act like tuning forks.

✔️ Use a Proper Wall Sleeve

Insulated penetrations prevent:

-

Rattling

-

Condensation drip noise

-

Copper abrasion

🌧️ 9. Weather & Moisture Considerations — The Pad Must Work All Year

Icon: 🌦️

Your condenser pad faces:

-

Rain

-

Freeze-thaw cycles

-

UV exposure

-

Settling soil

-

Pest activity

✔️ Storm-Proofing the Pad

-

Use UV-resistant pads

-

Grade soil away from the pad

-

Create drainage channels

-

Avoid mulch contact

-

Raise the pad if snow regularly exceeds 8–12 inches

✔️ Pest Control

Rabbits, rodents, and insects love warm condenser areas.

Use gravel, not mulch, immediately around the pad.

🏡 10. Sound Reflection & Placement — Even the Best Pad Can’t Fix a Bad Location

Icon: 🔊

Sound bounces off:

-

Walls

-

Fences

-

Decks

-

Concrete surfaces

This amplifies noise.

✔️ Place Condenser Away From Acoustic Reflectors

Minimum:

-

18–24 inches clearance

-

Preferably 4 feet in noisy installations

✔️ Use Shrubs or Acoustic Fencing (But Don’t Block Airflow)

Absorbs sound waves naturally.

✔️ Avoid Corner Installations

Corners multiply noise through reverberation.

🧭 11. Final Commissioning — The Quietness Test

Icon: 📋

After installing the pad and condenser, Savvy performs this final checklist:

🔍 Startup Test

-

No rocking

-

No rattling

-

No panel vibration

-

No copper movement

-

No excessive fan wobble

📐 Level Test

Unit must remain within 1° of level.

🔧 Vibration Test

Place a screwdriver on the condenser and rest the handle against your ear.

If you hear buzzing, adjustment is needed.

🔉 Sound Meter Check

Goodman condensers typically run at:

-

~55–70 dB depending on model

Anything above +5 dB indicates vibration transfer.

🌍 12. Why a Good Pad Is a Sustainability Tool

Icon: ♻️

This is where Savvy gets passionate.

A vibration-free, noise-controlled condenser pad contributes to:

🌱 1. Lower Energy Use

Reduced mechanical-resistance = reduced wattage draw.

🌱 2. Longer Compressor Life

Vibration = wear.

Less vibration = fewer replacements.

🌱 3. Reduced Refrigerant Leakage

Copper fatigue from vibration is a major leak source.

🌱 4. A Quieter, More Livable Neighborhood

Noise pollution matters.

🌱 5. Higher Real-World SEER2 Efficiency

Stable systems chill better.

A landing pad is more than concrete.

It’s climate efficiency, comfort, and longevity — all in one foundation.

🔗 Final Verified Resources (Maximum 6)

-

ACCA Installation Best Practices

https://www.acca.org -

EnergyStar Outdoor Unit Installation Guide

https://www.energystar.gov -

ASHRAE Noise & Vibration Control Standards

https://www.ashrae.org -

Building Science Corporation – Mechanical Systems & Noise Guidance

https://buildingscience.com -

EPA Outdoor Noise & Environmental Impact Resources

https://www.epa.gov

🌟 Closing: A Quiet System Isn’t an Accident — It’s an Engineered Experience

Your Goodman condenser is designed to operate efficiently, quietly, and reliably — but only if the landing pad beneath it is installed with intention.

When you craft a vibration-smart base with the right:

-

Groundwork

-

Pad type

-

Isolation materials

-

Anchoring

-

Airflow planning

-

Line set protection

…your system transforms from loud machinery into a quiet sustainability engine.

A well-built landing pad isn’t just a foundation.

It’s a promise — of longevity, efficiency, and the kind of comfort Savvy stands for.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: Refrigerant as a Climate Asset — Charging, Vacuuming & Protecting Your System Without Wasting a Single Gram