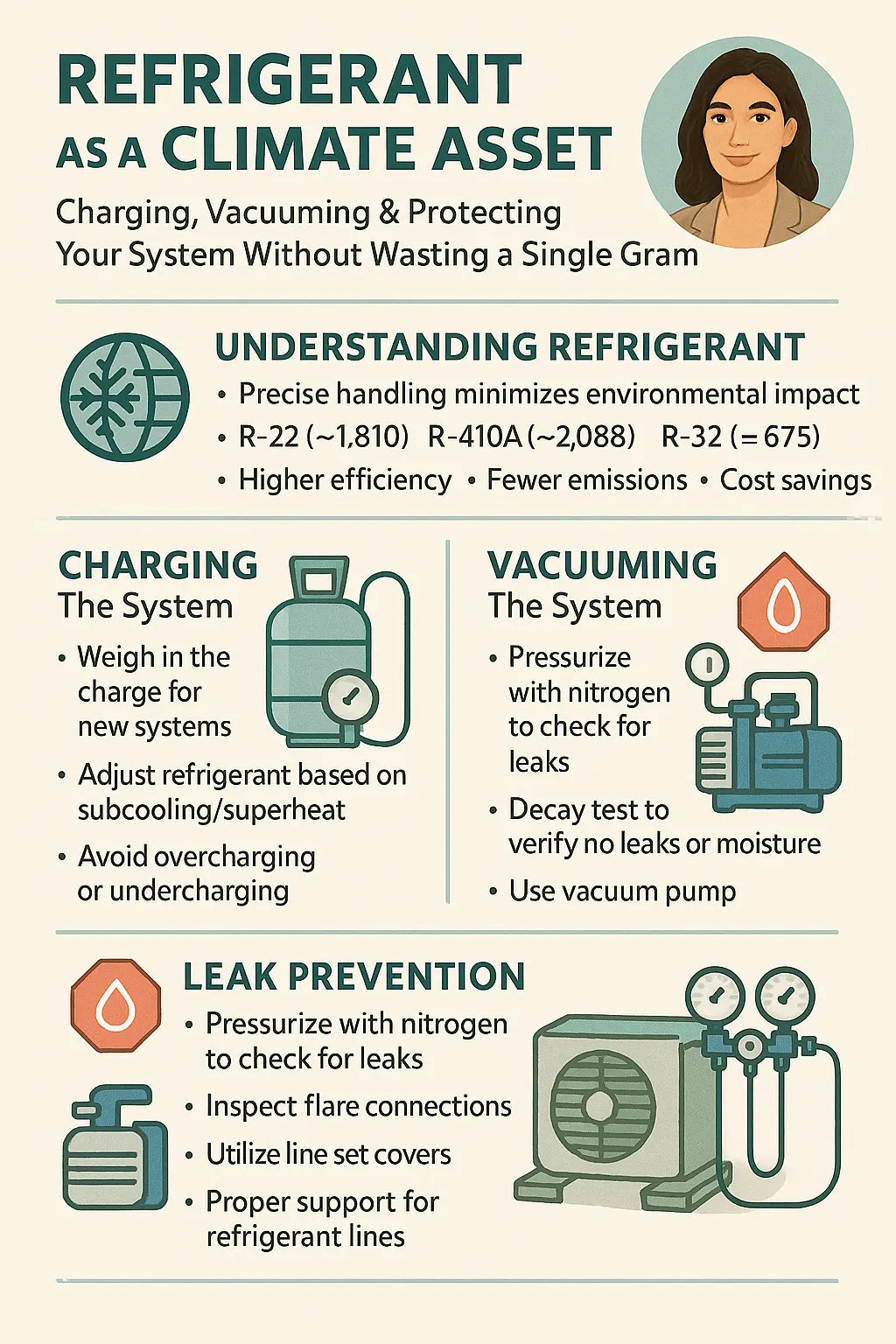

🌿 Introduction: Refrigerant Is Not Just a Chemical — It’s a Climate Asset

When homeowners hear the word “refrigerant,” they imagine coolant, cold air, or maybe the lines connecting their condenser and air handler. But Savvy wants you to see refrigerant for what it truly is:

A high-value climate resource with enormous heating and cooling potential — but also enormous environmental impact if mishandled.

Modern refrigerants like R-410A and especially R-32 are engineered to move heat incredibly efficiently. But they are also greenhouse gases, meaning that every gram released into the atmosphere has a measurable environmental footprint.

This is why charging, vacuuming, leak prevention, and refrigerant stewardship are not just “HVAC tasks.”

They are climate actions.

Today you’ll learn how to treat refrigerant like the precious, high-pressure, eco-important fluid it is — the Savvy way.

❄️ 1. Understanding Refrigerant as a Climate Asset

Icon: 🌎

Refrigerant isn’t consumed; it circulates.

If a system loses refrigerant, that means a leak exists, and the system is polluting.

🌍 Climate Impact Comparison

-

R-22 (legacy): ~1,810 GWP

-

R-410A: ~2,088 GWP

-

R-32: ~675 GWP

R-32 is the clear sustainability winner — which is why it's replacing R-410A in modern systems, including many Goodman and Daikin models.

Why Saving Every Gram Matters

-

Less environmental damage

-

Higher system efficiency

-

Lower homeowner energy costs

-

Longer compressor lifespan

-

More stable pressures & temperatures

-

Fewer service calls

Refrigerant is not just a “charge” — it is the lifeblood of the HVAC ecosystem.

🔧 2. Charging the System — The Science of Precision

Icon: ⚖️

Charging a refrigerant system (adding refrigerant) must be done with exactness. Both overcharging and undercharging reduce efficiency and increase emissions risk.

Method 1 — Weighing In the Factory Charge (Savvy’s Favorite)

This is the most precise method.

Steps:

-

Recover existing refrigerant safely

-

Pull a deep vacuum

-

Add refrigerant by weight based on nameplate

-

Adjust for line set length (typically +1–2 oz per 10 ft beyond factory allowance)

-

Compare superheat/subcool readings to manufacturer charts

Why It’s Perfect:

-

Zero guesswork

-

Zero overshoot

-

Zero unnecessary emissions

Method 2 — Subcooling Method (for TXV/EEV systems)

Most modern systems use TXVs.

Target:

-

Typically 8–14°F subcooling depending on manufacturer

If subcooling is too high:

-

Overcharge

-

Flooding risk

-

High head pressure

If too low:

-

Undercharge

-

Starving coil

-

Poor cooling capacity

Method 3 — Superheat Method (for fixed-orifice systems)

Target superheat varies with indoor/outdoor temperatures.

Why Savvy Treats Superheat Carefully:

-

Helps prevent compressor overheating

-

Ensures proper refrigerant boiling

-

Prevents slugging

🕳️ 3. Vacuuming the System — The Invisible Work That Saves the Compressor

Icon: 🧪

Removing air and moisture from the system before charging is the #1 most overlooked step in residential HVAC — but the most important for long-term sustainability.

Why Moisture Is the Enemy

When moisture reacts with refrigerant oil, it forms:

-

Hydrofluoric acid

-

Hydrochloric acid

These acids cause:

-

Compressor burnout

-

Copper plating

-

Restriction clogging

-

Dye contamination

-

Leak creation

Moisture also freezes at the metering device, causing intermittent cooling failures.

Savvy’s Vacuuming Standards (Not Negotiable)

1. Use a 2-stage vacuum pump

Single-stage pumps don’t achieve deep enough evacuation.

**2. Pull down to at least:

≤ 300 microns (ideal)

≤ 500 microns (acceptable)

This ensures both air and moisture are removed.

3. Perform a Vacuum Decay Test

Close the valves and watch the micron gauge.

If levels rise rapidly:

-

There’s moisture

-

Or a leak

-

Or a valve is not fully open

A stable micron reading means a system ready for charge.

4. Use Core Removal Tools

Schrader cores restrict flow.

Removing them improves evacuation speed by up to 90%.

5. Use a Digital Micron Gauge

Dial gauges are useless for vacuum work.

A digital micron gauge is the only precise way to measure dryness.

🛡️ 4. Leak Prevention — Protecting the Refrigerant You Just Saved

Icon: 🛑

Leak prevention is climate protection.

R-410A and R-32 operate at high pressures. Any flaw in copper, flares, or joints becomes a refrigerant escape path.

Savvy’s Leak-Proofing Checklist

✔️ 1. Nitrogen Pressure Test

Pressurize system to:

-

350–450 psi (R-410A)

-

450–550 psi (R-32)

Hold for several hours.

✔️ 2. Bubble Solution Testing

Electronic sniffers can miss slow leaks.

Soap never misses.

✔️ 3. Torque Every Flare to Specification

Under-torque → micro leaks

Over-torque → cracked flares

Always use a torque wrench.

✔️ 4. Protect Flare Ends from Contamination

Dust on the flare seat = guaranteed leak.

✔️ 5. Use Line Set Covers

They:

-

Reduce UV exposure

-

Prevent insulation decay

-

Protect copper from vibration

-

Reduce stress on flares

✔️ 6. Check for Vibrational Hot Spots

Copper must not touch:

-

Siding

-

Metal brackets

-

Wood studs

-

Concrete edges

Use rubber grommets or foam sleeves.

🧬 5. Refrigerant Management — How to Avoid Wasting a Single Gram

Icon: ♻️

Homeowners and installers often lose small amounts of refrigerant during:

-

Service

-

Charging

-

Repairs

-

Line set adjustments

-

Valve opening

But Savvy’s goal is zero loss.

🌱 Savvy’s Zero-Loss Refrigerant Practices

1. Always Recover Before Opening the System

Vent nothing. Recover everything.

EPA regulations require this — and Savvy agrees.

2. Use Low-Loss Fittings

These fittings prevent refrigerant blasts when hoses disconnect.

3. Purge with Refrigerant Minimally

Use nitrogen for line purges.

Use refrigerant only for final, tiny pressure stabilization.

4. Repair Instead of Top-Off

Topping off a leaking system is wasteful and environmentally harmful.

Find the leak, repair it, retest, then recharge.

5. Seal Schrader Cores with Nylog

Nylog Blue protects O-rings and threads from micro-leaks.

6. Compressor-Off Hose Removal

Always remove charging hoses when the system is off to minimize loss.

🏭 6. Protecting the System — Keeping Refrigerant Where It Belongs

Icon: 🔐

Even a perfectly charged system will lose efficiency if not properly protected.

1. Vibration Control

Vibration causes copper fatigue and microfractures.

Solutions:

-

Isolate line sets

-

Use rubber mounting feet

-

Install vibration pads under condensers

-

Avoid rigid metal contact points

2. UV Protection for Insulation

UV destroys insulation, causing:

-

Condensation

-

Line corrosion

-

Efficiency loss

Use UV-resistant line set covers.

3. Proper Condenser Clearance

Ensure:

-

18–24" on all sides

-

60" vertical clearance

Blocked airflow = high head pressure = wasted refrigerant energy.

4. Regular Maintenance (Savvy’s Seasonal List)

-

Clean coils

-

Tighten electrical connections

-

Inspect insulation

-

Check superheat/subcool each year

-

Look for oil stains (sign of leaks)

🧊 7. How Proper Refrigerant Handling Boosts Efficiency & Longevity

Icon: ⚡

A system with a perfectly maintained refrigerant charge delivers:

🌱 Higher SEER2 performance

Undercharging reduces capacity.

Overcharging increases watt draw.

🌱 Longer compressor life

Correct superheat = proper cooling of compressor windings.

🌱 Lower carbon footprint

A well-charged system consumes 10–30% less electricity.

🌱 Better home comfort

Stable temperatures

Better humidity removal

Quieter operation

🌱 Lower repair costs

Refrigerant starvation kills compressors.

Overcharge kills metering devices.

🌍 8. How R-32 Systems Change the Sustainability Landscape

Icon: 💧

R-32 is the refrigerant of the future — with:

-

Higher heat-carrying capacity

-

More efficient compression

-

Lower global warming potential

-

Lower charge volume requirement

This means system performance depends EVEN MORE on proper:

-

Vacuum

-

Charge

-

Leak-proofing

-

Handling discipline

Even a small release negates many sustainability benefits — so Savvy’s precision approach is essential.

🔗 Final Verified Resources

-

EPA Section 608 Refrigerant Handling

https://www.epa.gov/section608 -

EnergyStar HVAC Refrigerant Management Guidance

https://www.energystar.gov -

ASHRAE Refrigerant Standards & Safety

https://www.ashrae.org -

ACCA Refrigerant Charging Guidelines

https://www.acca.org -

Building Science Corporation – Refrigerant Circuit Insights

https://buildingscience.com

🌟 Closing: Refrigerant Is a Climate Responsibility — Treat It With Respect

Charging, vacuuming, and protecting refrigerant isn’t about tuning equipment —

it’s about safeguarding the planet.

When you:

-

Pull a perfect vacuum

-

Charge refrigerant with precision

-

Prevent leaks

-

Recover instead of vent

-

Protect line sets

-

Monitor system pressures

…you’re doing more than optimizing a Goodman or R-32 system.

You’re reducing greenhouse emissions, improving efficiency, and extending equipment life.

Refrigerant is a climate asset —

and when handled the Savvy way, not a single gram goes to waste.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: Smart Thermostat Pairing — The Secret to Making a 3-Ton Goodman System Feel Boutique-Level Efficient