🧠 1. Why PTACs Fail in Hotels (and Why Mike Designed This Package)

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Heat

Most hotel PTAC failures come from four predictable causes:

1️⃣ Airflow Restriction

Clogged filters, blocked intake grilles, drapes covering discharge, or furniture pushed too close.

2️⃣ Dirt, Debris & Neglected Coils

The #1 cause of overheating, compressor stress, and odor.

3️⃣ Electrical Overload or Undervoltage

Weak power, loose plugs, worn outlets, or improper breaker pairing.

4️⃣ Weather Intrusion

Wind-driven rain, poor sleeve slope, drain blockage, freeze-back issues.

DOE notes that improper maintenance and airflow restriction significantly reduce HVAC efficiency and lifespan:

🔗 https://www.energy.gov/energysaver/room-air-conditioners

Mike’s solution prevents all these common failures.

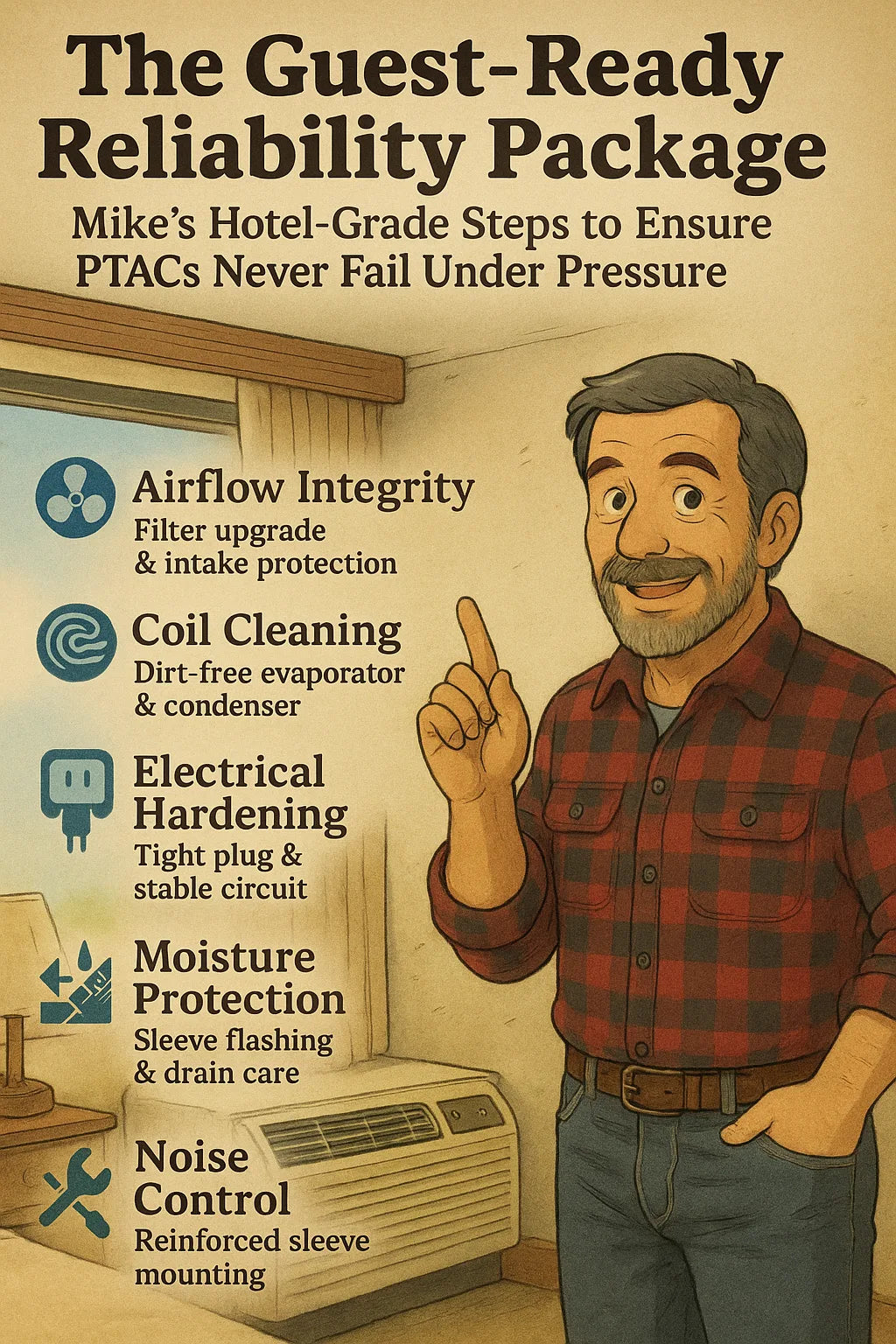

🛠️ 2. The Guest-Ready Reliability Package (GRRP) Overview

Mike’s reliability package has six pillars:

-

Airflow Integrity Enforcement

-

Deep-Clean Coil Protocol

-

Weather-Proof Sleeve Conditioning

-

Electrical Stability & Plug-Prep Hardening

-

Noise-Control Fastener Reinforcement

-

Preventive Maintenance Cadence (PMC)

Each pillar removes a major failure mode.

🌀 3. Airflow Integrity Enforcement: Mike’s Zero-Tolerance Airflow Rules

A clogged or blocked PTAC fails faster than any other scenario.

So Mike enforces airflow requirements with hotel-friendly solutions.

📥 A. Filter Upgrade to MERV 4–6 Washables

Hotel environments clog filters 5× faster than homes.

Mike uses:

-

Washable synthetic filters

-

Frame-stiffened inserts

-

Anti-mold rinse regimen

ASHRAE IAQ guidelines emphasize the importance of consistent airflow to prevent equipment stress

Mike’s Rule:

Filters are cleaned weekly, not monthly.

📐 B. Return-Air Guard System

Guests push furniture against PTACs.

Mike installs:

-

Return-air plastic stand-offs

-

Screw-in bumpers

-

Anti-block decals (low-profile)

These prevent suffocation of the intake.

🪟 C. Curtain-Lift or Curtain-Lock Accessories

Hotel drapes often smother airflow.

Mike adds:

-

Magnetic curtain standoffs

-

Rod extenders

-

Bottom curtain weights

This saves 20–30% airflow instantly.

🧼 4. Deep-Clean Coil Protocol (DCCP): Mike’s Anti-Odor, Anti-Failure Method

Dirty coils cause:

-

Smells

-

Weak cooling

-

Overheating

-

Compressor strain

-

Mold growth

EPA’s IAQ guidance notes coil contamination as a major contributor to poor indoor air quality:

🔗 https://www.epa.gov/indoor-air-quality-iaq

Mike’s DCCP cycle runs monthly in hotels.

A. Evaporator Coil Cleaning

-

Foaming non-acid cleaner

-

Soft-bristle coil comb

-

Rinse without flooding electronics

B. Condenser Coil Cleaning (Exterior)

-

Straighten fins

-

Remove mud, cottonwood, pollen

-

Flush from inside out

C. Blower Wheel Degunking

Airflow increases by up to 40% after cleaning dust-laden wheels.

D. Drain Pan & Channel Disinfection

Stops mildew and backflow.

Hotels that follow DCCP see 50–70% fewer cooling failures.

🌧️ 5. Weather-Proof Sleeve Conditioning

Hotels commonly have PTACs exposed to:

-

Rain

-

Salt air

-

Wind

-

Freezing conditions

-

Exterior corridor dust

Mike applies a 4-step conditioning system.

🌂 A. Sleeve Slope Verification

Correct slope: ¼ inch per foot outward.

Checked:

-

After installation

-

Seasonally

-

After building settling

🛡️ B. Exterior Flashing & Drip-Edge Reinforcement

Mike adds:

-

A secondary flashing lip

-

Moisture membrane tape

-

Aluminum or PVC drip shields

DOE recommends proper sealing of building penetrations to prevent moisture intrusion:

🔗 https://www.energy.gov/energysaver/air-sealing-your-home

🧼 C. Drain Path Clearing

Mike’s maintenance teams clear:

-

Drain holes

-

Condensate channels

-

Exterior louvers

Twice per month during peak season.

❄️ D. Freeze-Back Protection

In cold climates, water freezes in sleeves.

Mike installs:

-

Insulating pad behind chassis

-

Freeze-gap clearance at drain path

-

Directional louvers to minimize cold backflow

This prevents sleeve cracking and wall damage.

🔌 6. Electrical Stability & Plug-Prep Hardening

Hotel PTAC wiring is often overstressed.

Loose plugs and overheated outlets lead to:

-

Burn marks

-

Tripping

-

Voltage dips

-

Fire risks

-

Compressor startup failures

NFPA stresses proper outlet condition and circuit pairing to prevent overheating:

🔗 https://www.nfpa.org/codes-and-standards

Mike hardens every unit’s electrical system.

🔧 A. Outlet Replacement Cycle

Every 18–24 months:

-

The outlet is replaced

-

The plug is inspected

-

The cord is checked for heat damage

⚡ B. Breaker Match & Tightening

Mike ensures:

-

Correct breaker rating

-

Proper wire gauge

-

Tight terminal screws

Voltage drop kills PTACs.

🔌 C. Cord-Management Triangle

The cord must:

-

Never touch heater strips

-

Never coil behind furniture

-

Hang with proper slack

Mike installs cord keepers so housekeeping doesn’t accidentally push furniture into plugs.

🔇 7. Noise-Control Fastener Reinforcement

Hotel guests complain more about noise than temperature.

PTACs become noisy when:

-

The sleeve vibrates

-

Fasteners loosen

-

Chassis rubs against metal

-

Return panel flexes

-

Air leaks whistle

Mike uses his Quiet-Mount Fastener Map to eliminate vibration before it starts.

Steps include:

-

Triangular screw pattern

-

Neoprene washer installation

-

Composite shims for sleeve alignment

-

Torque-balanced anchoring

Result: whisper-quiet operation.

🧰 8. Preventive Maintenance Cadence (PMC)—Mike’s Hotel-Grade Schedule

Hotels cannot rely on “fix it when someone complains.”

Mike structures PM into three cycles:

🗓️ A. Weekly Mini-PM

-

Clean filters

-

Vacuum return grille

-

Check for drapes blocking airflow

-

Inspect for rattles or odors

Takes 90 seconds per unit.

📅 B. Monthly Reliability PM

-

Coil cleaning (DCCP)

-

Chassis slide-out inspection

-

Drain pan flush

-

Blower wheel check

-

Outlet & plug temperature test

-

Noise test

-

Reset thermostat calibration

🛠️ C. Annual Overhaul Cycle

-

Remove and deep-clean chassis

-

Inspect insulation pads

-

Replace fan motors if noisy

-

Test capacitor values

-

Replace outlet proactively

-

Check breaker torque

-

Pressure-wash condenser

-

Replace filter housing if warped

Following PMC reduces guest complaints by 60–80% and extends PTAC lifespan by 3–5 years.

🧭 9. Mike’s Hotel Performance Validation Tests

Before calling a unit “Guest-Ready,” Mike runs three final tests:

1️⃣ The Thermal-Load Room Test

Simulates:

-

High outdoor temperature

-

Maximum internal load

-

Occupied run cycle

He checks for:

-

Even temperature

-

Full cooling capacity

-

No short cycling

2️⃣ The Noise & Vibration Test

Measured at:

-

Low fan

-

High fan

-

Compressor on

-

Heat mode

Any squeal, rattle, or hum fails the test.

3️⃣ The Housekeeping-Impact Test

Mike simulates:

-

Curtains brushing the unit

-

Furniture bumping the grill

-

Cleaning carts passing

If airflow or sound changes, the unit needs reinforcement.

🎯 10. Why Mike’s Guest-Ready Reliability Package Works

Mike’s system works because it addresses the root causes of PTAC failure:

✔ Airflow Failure → Eliminated

✔ Dirt & Coil Fouling → Prevented

✔ Moisture Intrusion → Controlled

✔ Electrical Weak Points → Reinforced

✔ Noise Sources → Neutralized

✔ Maintenance → Systematized, not forgotten

Hotels using this system enjoy:

-

Fewer service calls

-

Better guest reviews

-

Lower HVAC replacement costs

-

Cleaner air

-

More predictable performance

-

Higher energy efficiency

As Mike says:

“A PTAC should work for 10 years—even in a hotel—if you treat it like a mission, not an appliance.”

And that’s exactly what the Guest-Ready Reliability Package delivers.

Buy this on Amazon at: https://amzn.to/47cH9ut

In the next topic we will know more about: The Wall-Truth Measurement System: How Mike Guarantees a Perfect PTAC Sleeve Fit Every Time