Why What You Do Right After Installation Determines Whether the Furnace Succeeds or Fails Over the Next 20 Years

Ask any rookie installer what matters most during a furnace install, and they’ll say:

“Hooking up the venting,” or “Connecting the thermostat,” or “Running the gas line.”

Ask Tony the same question, and he’ll tell you:

“The real install starts AFTER you turn it on.”

Because the first 10 minutes after firing up a brand-new furnace tell Tony everything about:

-

airflow

-

venting

-

gas supply

-

combustion

-

temperature rise

-

blower tuning

-

ECM profile

-

static pressure

-

staging

-

safety

-

reliability

-

real efficiency

A furnace can look perfect, be level, be vented properly, have clean electrical work, and STILL fail — if commissioning is ignored.

And here’s Tony’s warning:

“If you don’t commission it, you didn’t install it.”

This is Tony’s complete 10-minute startup and commissioning checklist — the one he teaches every apprentice and uses on every 90%-to-96%+ furnace, especially two-stage or ECM-driven units.

Let’s go step-by-step.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

🔌 1. Pre-Start Safety Check — Before You Hit the Switch

Before you ever energize the furnace, Tony runs a rapid inspection.

This takes 30–60 seconds and prevents disasters.

🧯 1.1 Gas Leak Test

Tony checks every joint:

-

drip leg

-

shutoff valve

-

manifold connection

-

union

-

flex connector

Using electronic detector + bubble test.

NFPA 54 requires leak testing before startup

Tony says:

“I don’t trust pipe dope. I trust bubbles.”

⚡ 1.2 Electrical Polarity and Grounding

Incorrect polarity will cause:

-

failure to ignite

-

board error codes

-

flame-sensing issues

-

premature component wear

Tony’s rule:

“If your ground sucks, your furnace will act possessed.”

🔥 1.3 Combustion Air Check

He makes sure:

-

intake is clear

-

exhaust is clear

-

no snow cover

-

no glued-shut intake screen

-

no room depressurization

EPA warns that improper combustion air causes CO production:

👉 https://www.epa.gov/indoor-air-quality-iaq

📏 1.4 Venting Slope Check

Condensing furnaces REQUIRE:

-

¼” per foot slope back toward furnace

-

no sags

-

no flat spots

-

correct pipe support

ICC venting rules:

👉 https://codes.iccsafe.org

Tony never trusts the vent until he inspects it personally.

🔥 2. Startup Sequence — Tony Watches the Furnace Like a Hawk

Most installers hit the switch, walk away, and wait for warm air.

Tony stays glued to the furnace during the ENTIRE ignition sequence.

Because the first 10 seconds reveal:

-

gas pressure problems

-

flame stability

-

inducer performance

-

igniter condition

-

venting issues

-

air starvation

Here’s Tony’s exact sequence.

⚙️ 2.1 Inducer Motor Check

When the furnace calls for heat:

-

Inducer starts

-

Pressure switch closes

-

Ignition cycle initiates

Tony listens for:

-

rattling

-

grinding

-

delayed startup

-

pressure switch flutter

-

gurgling (condensate issue)

Inducer sound tells Tony 50% of the story.

🔥 2.2 Igniter Check

Hot surface igniter should:

-

glow bright orange

-

not pulse or flicker

-

fire quickly

-

stay stable

Tony says:

“A lazy igniter means lazy flame.”

🌊 2.3 Flame Appearance

When gas lights, Tony looks for:

-

strong blue flame

-

even flame cones

-

no lifting

-

no rolling

-

no yellow tips

-

no delayed ignition pop

ASHRAE combustion guidelines:

👉 https://www.ashrae.org/technical-resources

A bad flame = bad fuel feed or venting.

🕓 2.4 Time to Flame Establishment

Furnace should:

-

ignite fully within 4–6 seconds

-

stabilize within 10 seconds

Anything longer means:

-

weak gas pressure

-

dirty manifold

-

incorrect line sizing

-

poor combustion air

🌬️ 3. Airflow Verification — The ECM Truth Test

Once the furnace fires, Tony immediately evaluates airflow.

This is where most installs fail.

ECM motors respond to system pressure — so if the ductwork is restrictive, the ECM “screams” by increasing torque.

🔧 3.1 Static Pressure Test (Tony’s Mandatory Check)

Tony attaches his manometer:

-

one probe before coil

-

one probe at return

-

total external static = supply + return

Targets:

-

0.50” WC max for most high-efficiency furnaces

-

0.60” WC max for larger ECM blowers

-

Anything over 0.70 = airflow failure

Documented by ACCA Manual D airflow standards:

Tony’s take:

“If your static is high, your system will die.”

🍃 3.2 Return Drop Velocity Check

Tony listens at the return grille.

If he hears:

-

whistling

-

roaring

-

suction noise

…the return drop is undersized or restrictive.

🔁 3.3 Filter Pressure Drop Test

High-MERV filters murder airflow unless the return is oversized.

Tony checks:

-

filter bending inward

-

drop > 0.20” WC

-

noise near the rack

Tony’s rule: “Big furnace = big return = big filter.”

🌡️ 4. Temperature Rise — The Heat Exchanger Lie Detector

Temperature rise is the fastest way to confirm:

-

airflow

-

heat exchanger health

-

proper gas input

-

proper staging

-

proper blower setup

Every furnace has a temperature rise range.

Common examples: 35–65°F.

Tony does this in the FIRST few minutes:

-

Measure return temperature

-

Measure supply temperature

-

Subtract

If rise is:

❌ Too high

= not enough airflow

= return drop wrong

= coil clogged

= high static

= filter too restrictive

❌ Too low

= overfeeding gas

= blower running too fast

= improper tuning

Tony’s rule:

“Temperature rise is the system’s confession.”

🔥 5. Gas Pressure & Fuel Input — No Guessing Allowed

Now Tony checks the fuel supply.

🔧 5.1 Manifold Pressure Test

Natural gas target: 3.5” WC

Propane target: 10–11” WC

If pressure drops when the furnace hits high stage → gas line is undersized.

This is confirmed by NFPA 54:

👉 https://www.nfpa.org

Tony says:

“If the flame shrinks in high stage, your gas line is trash.”

🧮 5.2 Meter Clocking (Tony’s Favorite Trick)

He clocks the gas meter to verify BTU input.

If a 100k furnace is only receiving 70–80 CFH, it’s starved.

Most installers don’t clock meters.

Tony does it on EVERY install.

🧊 6. Condensate System — The Most Overlooked Failure Point

During startup, condensate begins forming immediately.

Tony checks:

-

trap orientation

-

correct slope

-

no gurgling

-

pump activation

-

drain termination

-

freeze protection

IPC and IMC require slope of ¼” per foot:

👉 https://codes.iccsafe.org

Tony adds:

“If I hear bubbling, I know someone screwed up the trap.”

📡 7. Control Board & ECM Setup — Tuning the Furnace for Reality, Not Theory

Factory settings almost NEVER match the home’s ductwork.

Tony reprograms:

-

CFM per ton

-

heating blower speed (low & high stage)

-

cooling airflow

-

delay-on timer

-

delay-off fan timer

-

staging logic

-

anti-short-cycle timers

This is where the furnace goes from “installed” to mastered.

Tony says:

“Factory settings don’t know your ductwork.

I do.”

🎧 8. Sound Check — The Furnace Should Disappear

Quiet furnaces don’t happen by accident.

Tony listens for:

✔ return whistling

→ undersized drop or filter

✔ inducer resonance

→ poor vent slope or water pooling

✔ blower hum

→ high static

✔ plenum boom

→ wrong transition or no cross-breaking

✔ coil whistle

→ high face velocity

If a furnace is loud, Tony doesn’t leave until it’s silent.

🧪 9. Safety Systems — Tony’s Rapid Verification

Tony checks:

-

flame sensor signal

-

pressure switch trip point

-

rollout switches

-

high limit

-

drain float switch

-

condensate pump safety

-

board error logs

He tests each safety manually.

Tony’s rule:

“If a safety can trip, I want it to trip in front of ME, not the homeowner.”

📄 10. Documentation — Tony Never Leaves Without It

The LAST thing Tony does?

He hands the homeowner (or builder) complete documentation:

-

static pressure readings

-

temperature rise

-

manifold pressure

-

BTU input

-

blower setup profile

-

venting inspection notes

-

model/serial numbers

-

commissioning sheet

Why?

Because it proves the job was done right.

And if something goes wrong later, Tony can say:

“Not my install.

Here are the numbers.”

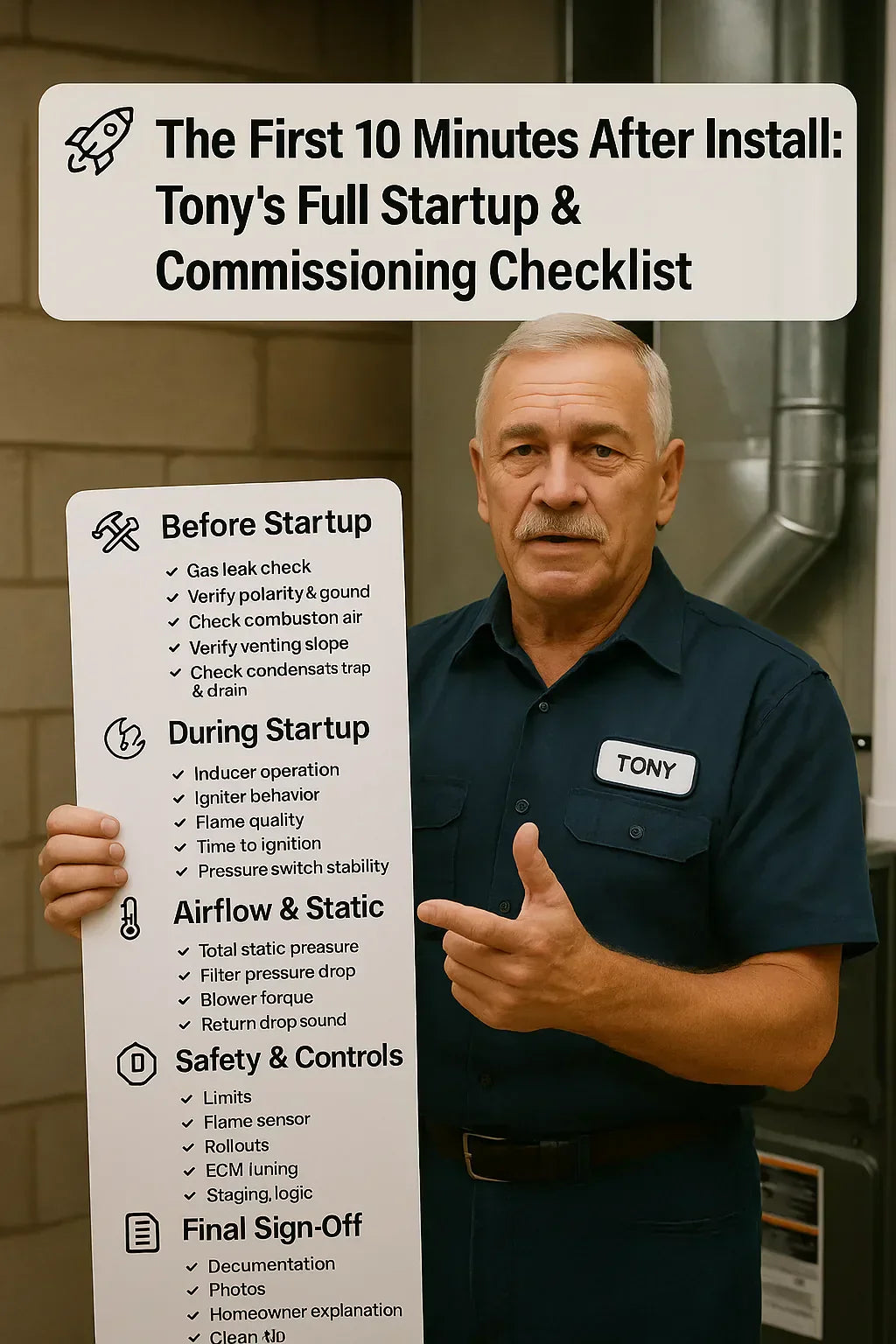

🏁 **Tony’s Complete 10-Minute Commissioning Checklist

(Printable Summary)**

Here is Tony’s exact rapid process:

1. Before Startup

🔧 Gas leak check

⚡ Verify polarity & ground

🧯 Check combustion air

📏 Verify venting slope

💧 Check condensate trap & drain

2. During Startup

🌀 Inducer operation

🔥 Igniter behavior

🌊 Flame quality

⏱️ Time to ignition

🔁 Pressure switch stability

3. Airflow & Static

📉 Total static pressure

🍃 Filter pressure drop

🌀 Blower torque

🔉 Return drop sound

4. Heating Performance

🌡️ Temperature rise

🔥 Gas manifold pressure

🧮 Meter clocking

5. Condensate System

💧 Trap prime

🚰 Drain flow

🧊 Freeze protection

6. Safety & Controls

🛑 Limits

🔥 Flame sensor

🔁 Rollouts

📡 ECM tuning

🧠 Staging logic

7. Final Sign-Off

📝 Documentation

📸 Photos

📚 Homeowner explanation

🧼 Clean-up

🔥 Final Word from Tony

“Anybody can install a furnace.

Only pros COMISSION one.

The first 10 minutes decide whether that furnace will:

-

run quiet

-

run clean

-

run safe

-

run efficient

-

last 20 years

Or whether it’ll spend its life tripping limits, wasting gas, overheating, and breaking down.”

Tony always ends with the same line:

“Don’t trust the install. Trust the numbers.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: The 3 Tools Tony Never Installs a High-Efficiency Furnace Without — And Why Every DIYer Gets This Wrong