The Field-Tested Instruments That Separate Installers From Parts-Changers — And Why Your Furnace Will Never Run Right Without Them

Every DIYer thinks installing a new furnace is about:

-

hooking up the vent pipe

-

connecting the gas line

-

wiring the thermostat

-

sliding the furnace into place

-

soldering or taping some ductwork

But that’s the easy part.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

Tony will tell you:

“Anyone can install a furnace.

Only pros can COMMISSION one.”

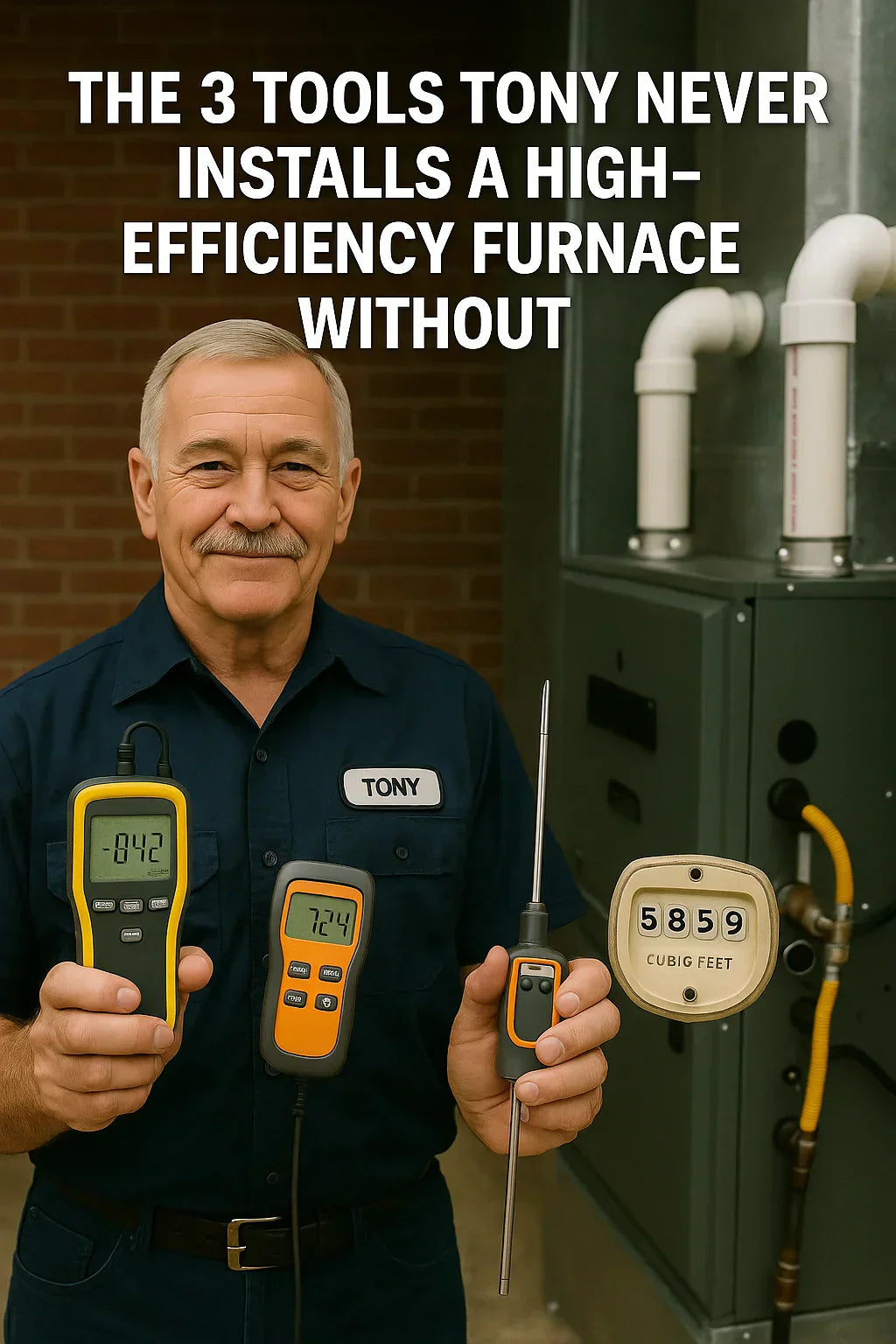

And to commission one properly — especially a high-efficiency 96%+ furnace like the Goodman GR9T961004CN — Tony never shows up without three tools.

Not cordless drills.

Not snips.

Not wrenches.

Not levels.

Those help you install the furnace.

But the three tools below determine whether your furnace will:

-

run efficient

-

run quiet

-

run safe

-

last 20+ years

-

heat evenly

-

burn clean

-

stage properly

-

stay in warranty

-

avoid callbacks

Or whether it will:

-

short-cycle

-

overheat

-

go into error codes

-

produce CO

-

kill its ECM blower

-

burn your gas bill

-

freeze the coil

-

never hit its rated 96% efficiency

This is Tony’s complete guide to the three “non-negotiable commissioning tools” every professional uses — and the reason every DIY install goes wrong without them.

#1 — 📉 A Digital Manometer

The Only Tool That Tells You Whether the Furnace Can Actually Breathe

This is Tony’s #1 tool.

No exceptions.

No substitutes.

A digital manometer measures:

-

total external static pressure (ESP)

-

gas manifold pressure

-

pressure switch operation

-

inducer performance

-

venting stability

Without this tool, you cannot know:

-

whether airflow is correct

-

whether ductwork is restrictive

-

whether the ECM blower is maxing out

-

whether the heat exchanger is overheating

-

whether the coil is starving for air

-

whether negative pressure is causing combustion issues

-

whether your vent is drafting properly

ACCA Manual D considers static pressure the #1 indicator of duct system performance

Tony’s rule is simple:

“If you didn’t measure static pressure, you didn’t set up the system.

You just gambled with a $5,000 machine.”

🌀 Why DIYers Always Skip This Tool

Because they look at airflow like they look at Wi-Fi:

“If air is coming out of the vents, it must be fine.”

Wrong.

Airflow is physics — not guesswork.

A two-stage ECM furnace may be moving air, but:

✔ at the wrong CFM

✔ at the wrong static pressure

✔ at the wrong torque

✔ at the wrong filter face velocity

✔ with the wrong temperature rise

That means the furnace is running wrong, even if it “feels fine.”

A manometer reveals the truth instantly.

📊 Tony’s Static Pressure Targets

For almost all high-efficiency furnaces:

-

0.50” WC max (ideal)

-

0.60” WC acceptable for large systems

-

0.70”+ WC = airflow failure

-

1.00”+ WC = ductwork redesign required

Tony’s take:

“Static pressure is the furnace’s blood pressure.

High static = the system is dying.”

🔥 The Manometer Also Confirms Gas Delivery

Manifold pressure must be:

-

3.5” WC for natural gas

-

10–11” WC for propane

If manifold pressure drops during high fire, your gas line is undersized — a common DIY mistake.

🧪 The Manometer Checks the Pressure Switch Too

A pressure switch that chatters or opens during operation may cause:

-

inducer lockouts

-

ignition failure

-

nuisance shutdowns

Tony tests the switch with the manometer to confirm:

-

vacuum stability

-

inducer performance

-

venting slope

-

condensate drainage

This is why Tony never skips this tool.

#2 — 🌡️ A Digital Thermometer (for Accurate Temperature Rise)

The Only Way to Prove the Furnace Is Burning Clean and Breathing Right

Every furnace has a temperature rise specification — typically something like:

35°F – 65°F

That means:

-

Supply temperature

minus -

Return temperature

…must fall within that range.

If rise is too high, the furnace is starving for air.

If rise is too low, gas input or blower setup is wrong.

DOE documentation stresses temperature rise as a core commissioning measurement:

👉 https://www.energy.gov/energysaver/furnaces-and-boilers

Tony’s rule:

“Temperature rise is the furnace’s confession.

It tells you whether airflow and gas input are right — or completely wrong.”

❌ What DIYers Do Instead

They put their hand over a register and say:

“Feels warm.”

Tony laughs at this.

Your hand cannot tell the difference between:

-

85°F supply air

-

110°F supply air

-

135°F overheating disaster air

A digital thermometer can.

📊 Tony Uses the Temperature Rise to Diagnose Everything

A bad temperature rise can mean:

✔ undersized return

✔ restrictive filter

✔ dirty coil

✔ blower not tuned

✔ wrong static pressure

✔ incorrect gas input

✔ mismatched venting

✔ clogged secondary heat exchanger

✔ condensate pooling

✔ gas starvation

✔ blower RPM error

Temperature rise is a MASTER diagnostic tool.

🔥 The Heat Exchanger Depends on It

Even a small airflow issue can increase rise by 15–30°F, and over time:

-

stresses metal

-

warps cells

-

causes premature cracks

-

triggers limit switch cycling

This is why EPA guidelines require airflow verification during furnace commissioning:

👉 https://www.epa.gov/indoor-air-quality-iaq

Tony doesn’t leave a site unless temperature rise is PERFECT.

#3 — 🧮 The Gas Meter Clock (for BTU Input Testing)

The Ultimate Tool That Exposes Gas Line Starvation — The Most Common DIY Failure

This tool doesn’t ship with the furnace.

But every pro carries one in their brain.

Clocking a gas meter means measuring:

-

how many seconds it takes for the meter to rotate

-

converting this to cubic feet per hour (CFH)

-

verifying BTU input matches the furnace rating

This is pure math — and it reveals the TRUTH about whether your furnace is getting the gas it needs.

Tony’s rule:

“If you didn’t clock the meter, you didn’t verify BTU input.

And if you didn’t verify BTU input, you didn’t install the furnace correctly.”

🧮 The Formula (Tony’s Version)

-

Turn off all other gas appliances.

-

Let furnace run in high stage.

-

Time one revolution of the smallest test dial.

-

BTU/hr = CFH × 1,000

If the furnace is rated for 100,000 BTU, but the meter shows:

-

75,000 BTU input → starved

-

60,000 BTU → severely starved

-

50,000 BTU → guaranteed comfort issues

This is why Tony says:

“You bought a 100k furnace. But your gas line is only feeding it 70k.

That’s not installation — that’s malpractice.”

📉 Gas Starvation Is Everywhere

DIYers assume:

-

“The old furnace worked fine.”

-

“The pipe is already there, so it must be right.”

-

“The gas line looks big enough.”

None of that is true.

IFGC pipe capacity tables prove most gas lines are undersized:

👉 https://codes.iccsafe.org/content/IFGC2021P2/chapter-4-gas-piping-installations

Tony teaches that ½" pipe almost always fails past 20–30 feet, especially with elbows and multiple appliances.

💥 The Biggest DIY Mistake: Installing Without Measuring Anything

DIYers install furnaces like this:

-

hook up gas

-

connect flue

-

connect thermostat

-

turn it on

They never measure:

-

static pressure

-

temperature rise

-

BTU input

-

manifold pressure

-

filter pressure drop

-

blower torque

-

venting vacuum

-

inducer performance

Tony’s summary:

“You can’t tune what you didn’t measure.

And you can’t trust what you didn’t tune.”

🧠 Why These Three Tools Matter Even MORE on High-Efficiency Furnaces

High-efficiency furnaces are NOT plug-and-play.

They require:

-

proper vent slope

-

proper condensate drainage

-

BTU input verification

-

precise airflow tuning

-

ECM blower table programming

-

staging calibration

-

return drop sizing

-

filter face velocity control

-

static pressure balancing

These systems are engineered to run at:

-

tight tolerances

-

low excess air

-

high efficiency

-

low noise

-

stable combustion

They CANNOT run correctly without:

-

A manometer

-

A digital thermometer

-

The gas meter clock test

Tony’s version:

“A high-efficiency furnace without commissioning is a grenade without a pin.”

🛠️ **Tony’s 10-Minute Commissioning Routine

(Using the Three Tools)**

Here’s how Tony uses all three tools in sequence.

Step 1 — Check gas pressure with the manometer

-

inlet pressure

-

manifold pressure

Step 2 — Clock the meter

-

verify BTU input

-

confirm furnace is fed properly

Step 3 — Measure total static pressure

-

supply + return

-

verify duct performance

Step 4 — Measure filter pressure drop

-

confirm correct filter rack sizing

Step 5 — Tune blower speeds

-

adjust low & high stage CFM

Step 6 — Measure temperature rise

-

verify heat exchanger performance

Step 7 — Final gas pressure verification

-

ensure stability after blower tuning

Step 8 — Document everything

-

readings

-

model/serial

-

setup profile

Tony never leaves without this data.

🏆 Tony’s “No-Compromise” Rule

“If you see an installer without these three tools,

you’re not looking at a furnace technician.

You’re looking at a parts changer.”

🔥 Final Word from Tony

“Installing a furnace takes skill.

Commissioning it takes science.

A high-efficiency furnace is a precision machine.

If you don’t measure gas, air, temperature, and pressure — you didn’t set it up right.

Every DIYer gets this wrong because they install furnaces the way you’d install a microwave.

But a furnace isn’t an appliance.

It’s a combustion system, an airflow system, and a pressure system — all in one.”

“And that’s why I never arrive without:

-

A manometer

-

A digital thermometer

-

The gas meter clock test

If you’re missing even ONE, the system WILL fail.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: Why Your Furnace Won’t Hit 96% Unless You Install the Venting Like This