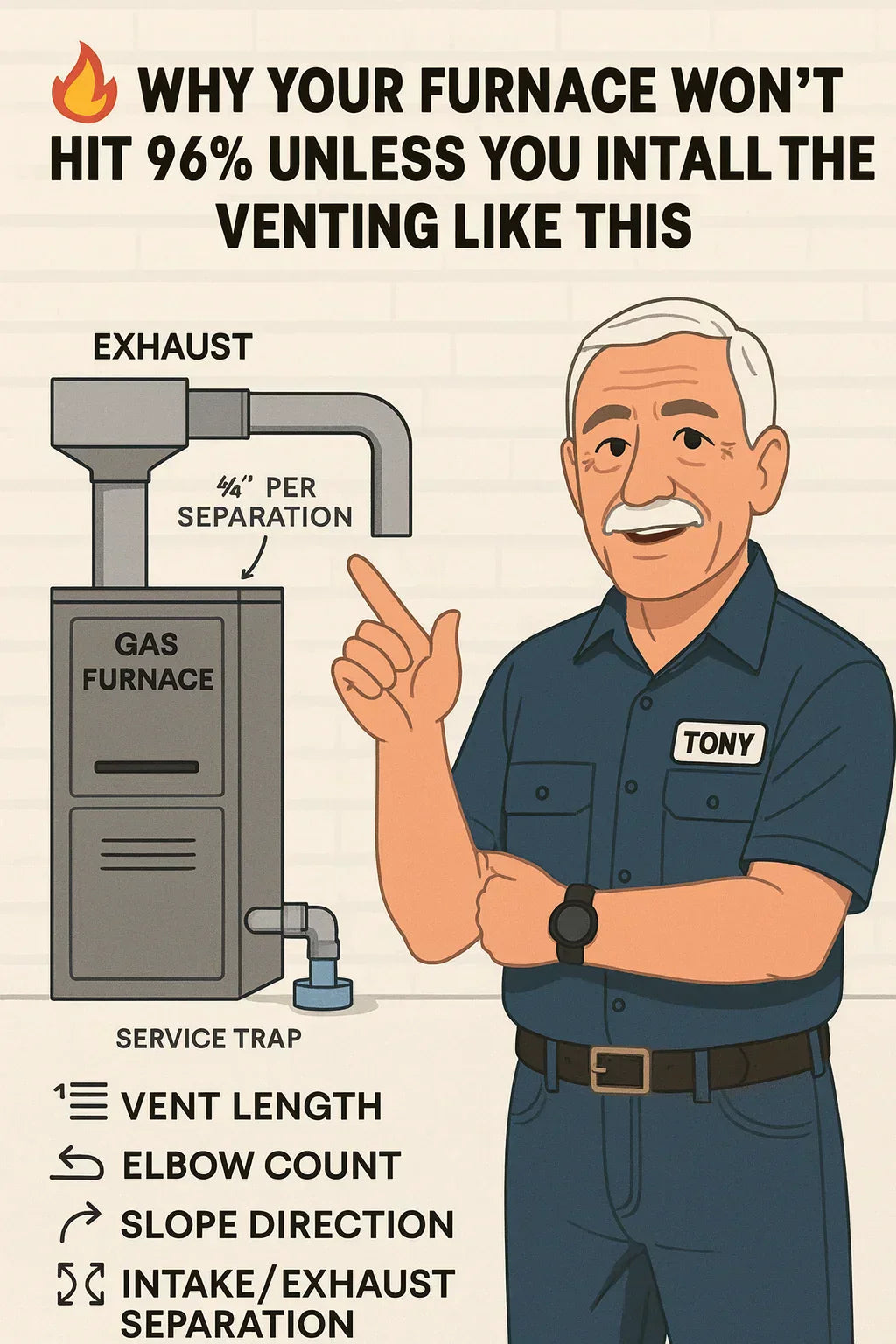

Tony’s No-Nonsense Guide to Getting Real Efficiency Out of Your Goodman Two-Stage Furnace

Model Reference: Goodman GR9T961004CN 96% AFUE 100,000 BTU Two-Stage Gas Furnace

Most homeowners think a 96% furnace automatically runs at 96% efficiency.

Wrong.

A 96% AFUE furnace can hit that rating — but only if the venting is installed correctly.

Mess up the vent length? Efficiency drops.

Use too many elbows? Efficiency drops.

Slope the pipe the wrong way? Efficiency drops and the furnace leaks condensate like a bad roof.

Today, Tony is pulling the curtain back on the part of furnace installation nobody talks about:

how venting design alone can swing your true efficiency from 96% down to 88% — or worse.

This is real-world, boots-on-the-ground, installer-tested guidance. Follow it, and your Goodman 96% furnace will run like the engineering team intended. Ignore it, and your system will short-cycle, corrode, whistle, leak, and give you temperature splits that make no sense.

Let’s get into it.

🧭 1. What “96% AFUE” Actually Means in the Field — Not in a Lab

Most people misunderstand AFUE. 96% means:

For every $1 of gas burned, $0.96 becomes usable heat — if the installation meets the test conditions.

Here’s the catch:

AFUE ratings are measured under an ideal setup with:

-

perfect vent length

-

perfect slope

-

perfect intake/exhaust separation

-

perfect pressure balance

-

perfect combustion tuning

-

perfect drain configuration

Once the furnace is in your attic, basement, or closet, the lab world is gone. You’re in Tony’s world now — and the building is the battlefield.

According to the U.S. Department of Energy, venting errors are one of the top causes of reduced furnace efficiency and premature failure.

Source: https://www.energy.gov/energysaver/furnaces-and-boilers

Your goal as an installer: replicate the lab conditions as closely as possible.

And it all starts with venting.

📏 2. The Single Biggest Mistake: Wrong Vent Length (Too Long or Too Short)

The Goodman GR9T961004CN furnace requires PVC venting within specific friction-loss limits.

If you exceed those limits, your furnace can’t pull or push enough air through the combustion chamber — and the unit “detunes” itself.

✔ Too Long =

-

Reduced combustion air

-

Weak exhaust scavenging

-

Lower temperature split

-

More condensate pooling

-

Increased CO risks

-

Lower actual efficiency

✔ Too Short =

-

Excessive draft

-

Over-rapid combustion

-

Pressure switch trips

-

Flame disturbance

-

Heat exchanger stress

Goodman provides exact vent length charts. (See their install manual or AHRI guidelines.)

But Tony’s summary rule is this:

Your vent length must be long enough to establish stable draft, but short enough to stay inside the furnace’s pressure limits.

If you slap the vent together without reading the chart?

You just turned a 96% furnace into an 89% furnace.

🔄 3. Elbow Count — Why Every 90° Elbow Acts Like 5–8 Feet of Pipe

Every sharp 90° elbow adds resistance to airflow. Most installers forget this.

A “simple 10-foot run” with six elbows is really a 40-foot equivalent run.

Equivalent lengths are published by ASHRAE:

https://www.ashrae.org/technical-resources

Tony’s rule:

Every elbow must be justified with airflow math. No exceptions.

Even two unnecessary elbows can push your total run past Goodman’s limits — and there goes your efficiency.

Pro tip Tony teaches new techs:

Design venting on paper first. If you’re sketching elbows instead of straight runs, you’re already losing efficiency.

📐 4. Slope Matters More Than Most Installers Think (¼" per Foot or You’re Done)

A condensing furnace creates water. And that water must flow downhill back to the furnace to the condensate trap — not toward the termination.

The correct slope for PVC venting is:

✔ ¼ inch per foot toward the furnace

Anything less?

-

Water pools

-

Water freezes

-

Water blocks exhaust

-

Pressure switches fail

-

Heat exchangers rot

-

Efficiency plummets

According to ICC and NFPA guidelines, improper slope is a major cause of vent restriction in high-efficiency furnaces.

Reference: https://codes.iccsafe.org

Tony says it bluntly:

If the pipe isn’t sloped right, the furnace is suffocating — just slowly.

🌬️ 5. Intake vs. Exhaust Separation — The Silent Efficiency Killer

Your Goodman furnace uses two PVC pipes:

-

Intake (fresh air)

-

Exhaust (flue gases)

If they are too close at termination, the furnace can suck its own exhaust back into the intake.

That instantly tanks your combustion efficiency.

✔ Tony’s Separation Rules

-

Minimum: Follow Goodman’s required inches

-

Ideal: 3 feet of horizontal separation

-

Never: Terminate inside corners or alcoves

-

Always: Keep the intake in clean, oxygen-rich air

ASHRAE warns that poor termination placement can cause outside air recirculation

Tony’s take:

“If your intake smells the exhaust, your efficiency is dead before the furnace even lights.”

💧 6. Condensate Drain & Trap — The Part Every Installer Underestimates

A 96% furnace makes a lot of water.

If that water can’t move, the furnace loses efficiency because the heat exchanger stays wet — not dry.

Here are Tony’s rules:

✔ Install the trap EXACTLY as the manual shows

No guessing. No “close enough.”

The trap height balances pressure.

✔ Use a dedicated drain line

Never tie into a line that can backflow.

✔ Slope the drain line

¼ inch per foot, always.

✔ Insulate the drain in unconditioned spaces

Frozen condensate = furnace shutdown.

DOE guidelines emphasize that high-efficiency equipment must have correct condensate management

Tony says:

“Wet heat exchangers don’t transfer heat. They just rust slower.”

📣 7. Furnace Room Pressure Balance — The Hidden Reason Efficiency Falls Apart

Most installers never measure room pressure.

Tony always does.

A 96% furnace depends on stable combustion. If the furnace room is under negative pressure because of:

-

a dryer

-

a bathroom fan

-

a kitchen hood

-

a return leak

-

a poorly sealed closet

…your intake numbers change, your draft weakens, and your furnace loses efficiency.

ASHRAE ventilation standards discuss this balance:

https://www.ashrae.org/technical-resources/bookstore/standards-62-1-62-2

Tony’s rule:

Any room housing a high-efficiency furnace must not be starved for air. Ever.

📊 8. Pressure Switch Settings — The Furnace’s “Truth Detector”

A pressure switch is not just a safety device — it’s the efficiency watchdog.

If your venting is wrong:

-

The pressure switch opens

-

The furnace derates

-

Your staging changes

-

The ECM blower compensates

-

Fuel-to-air ratio shifts

-

AFUE drops

Tony’s field test method:

-

Fire the furnace.

-

Check the inducer pressure at high stage.

-

Compare to Goodman’s spec.

-

If it’s off by more than ±0.1", your venting design is wrong.

Simple as that.

🧰 9. The Tools You Actually Need (Not What You Think)

Most installers bring:

-

Saw

-

Level

-

Glue

-

Tape measure

Tony brings:

-

Digital manometer

-

Borescope

-

Combustion analyzer

-

Low-pressure gauge kit

-

Digital level (0.1° accuracy)

-

Thermal camera

Because you can't “eyeball” a 96% furnace into efficiency.

🏁 10. Tony’s Perfect 96% Venting Blueprint (Follow This, and You’re Golden)

✔ 1. Plan the run on paper

Keep elbows minimal. Straight lines always win.

✔ 2. Stay within Goodman’s equivalent length charts

Every elbow counts as friction loss.

✔ 3. Maintain ¼" slope per foot back to furnace

Water must move toward the trap.

✔ 4. Terminate intake and exhaust far apart

Avoid rebreathing combustion gases.

✔ 5. Install the condensate trap exactly as shown

Don’t modify it.

✔ 6. Use a combustion analyzer on start-up

Raw numbers are the only truth.

✔ 7. Confirm inducer pressure is in spec

If it’s out of range, efficiency collapses.

✔ 8. Test for negative room pressure

Your furnace must breathe.

✔ 9. Insulate vent sections in cold spaces

Frozen exhaust = no efficiency.

✔ 10. Test again after 10 minutes of run time

Venting performance changes as materials heat.

Do all of the above, and your furnace will actually hit 96% AFUE.

Skip even one?

You’re installing an 88–92% furnace pretending to be a 96% system.

🧨 Final Word from Tony

“Your Goodman furnace is a precision machine — not a water heater in a box.

Treat the venting like a science project, not a chore.

If the venting isn’t perfect, the efficiency isn’t real. Period.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: The Filter Rack Trap — Why 90% of Installers Starve a Two-Stage Furnace on Day One