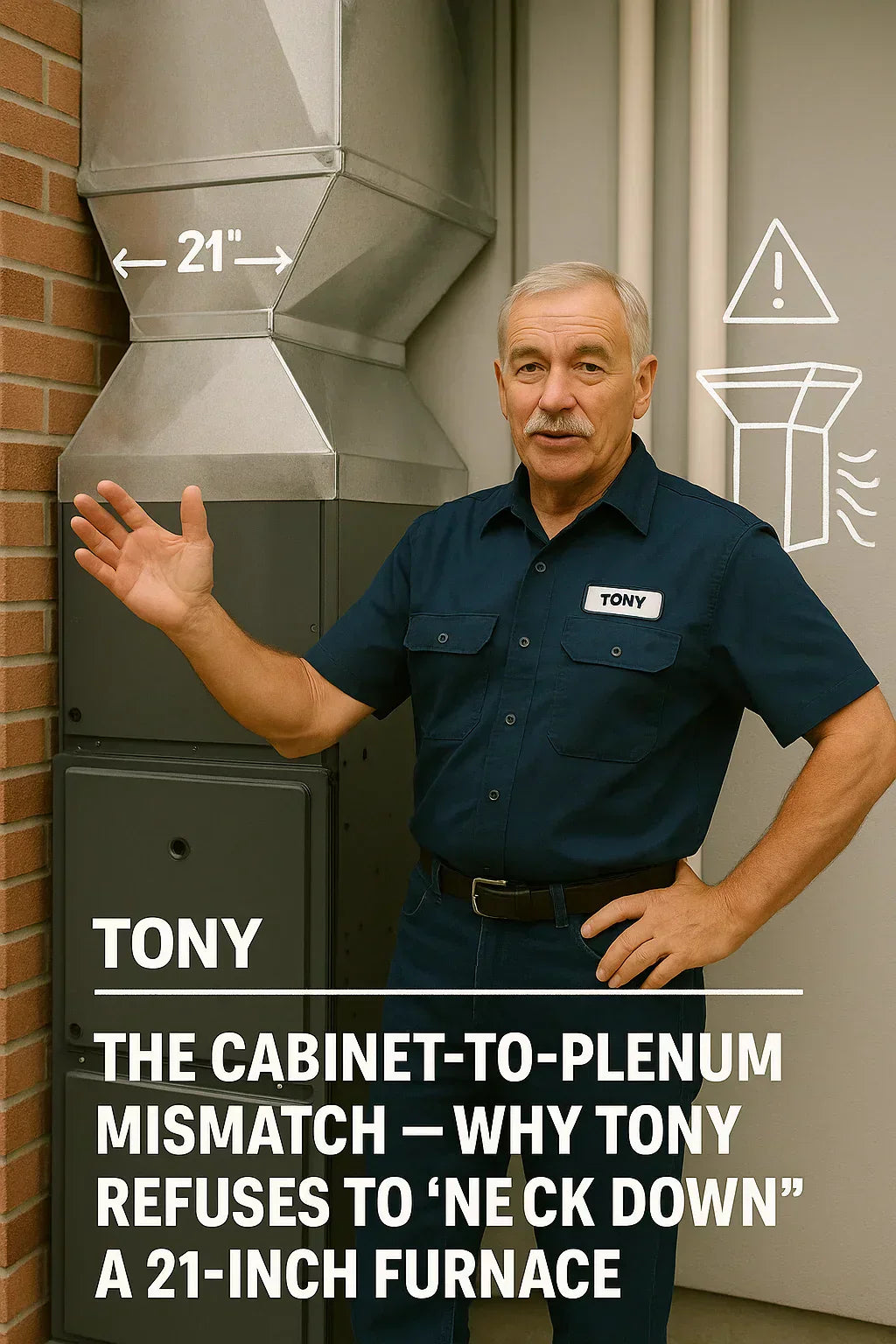

The Airflow Crime That Destroys Efficiency, Causes Noise, and Shortens Heat Exchanger Life

Tony has three hard rules when installing a modern high-efficiency furnace:

-

Never starve the blower.

-

Never force the heat exchanger to run hotter than designed.

-

Never neck down a 21-inch cabinet into a tiny supply plenum.

That last rule gets broken every day by rushed installers, lazy retrofit jobs, and “we’ve always done it this way” thinking.

But here’s the truth Tony teaches every apprentice:

“When you neck down a 21-inch furnace to an 18-inch plenum, you’re turning a $3,000 machine into a $300 mistake.”

It’s not just sloppy sheet metal work — it’s a direct attack on airflow physics. It causes high static pressure, temperature instability, noise, blower stress, short cycling, premature failure, and reduced heating AND cooling performance.

Most importantly:

A mismatched plenum is the #1 reason a high-efficiency furnace never hits its rated efficiency.

This article is Tony’s complete blueprint on why “neck downs” are airflow killers — and how to build a proper plenum that lets a modern ECM blower breathe freely.

Let’s get into the hard truths.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

🏗️ 1. Why Modern Furnaces Are Wider (and Why That Matters for Airflow)

Twenty years ago, many furnaces were 14–17 inches wide.

Older blowers were small, PSC (permanent split capacitor) motors, and lower BTU units pushed less airflow.

But today’s furnaces — especially 96% two-stage units with ECM blowers — need:

-

more heat exchanger surface area

-

larger blower wheels

-

wider secondary heat exchangers

-

more internal air volume

-

increased CFM for cooling matchups

That’s why systems like the 21-inch Goodman GR9T961004CN exist.

DOE documentation on high-efficiency equipment stresses that modern units require larger airflow cross-sectional area and low external static to operate properly:

👉 https://www.energy.gov/energysaver/furnaces-and-boilers

Tony sums it up like this:

“They made the furnace bigger for a reason. You need to give the air somewhere to go.”

📉 2. What Happens When You “Neck Down” a 21-Inch Furnace into a 16–18-Inch Plenum

Installers often reduce the furnace outlet to fit an old plenum.

That reduction — often called a “neck down” — might only be:

-

21" → 18" (3 inches)

-

or 21" → 16" (5 inches)

But that reduction cuts cross-sectional area dramatically.

Example:

-

21" x 20" = 420 sq in

-

18" x 20" = 360 sq in (15% reduction)

-

16" x 20" = 320 sq in (24% reduction)

That’s BEFORE elbows, coils, or ductwork friction.

ASHRAE duct design guidelines warn that sudden reductions in cross-sectional area create massive turbulence and static pressure spikes:

👉 https://www.ashrae.org/technical-resources

Tony puts it in plain terms:

“You’re choking the furnace at the throat.”

Let’s break down the consequences.

🔥 3. Consequence #1 — High Temperature Rise (Deadly for Heat Exchangers)

High temperature rise = not enough airflow across the heat exchanger.

A furnace like the GR9T961004CN has a specific temperature rise window.

If airflow drops due to a necked-down plenum:

-

heat exchanger overheats

-

limit switch trips

-

metal fatigues

-

cracks develop over time

This is one of the fastest ways to destroy a heat exchanger.

EPA documentation ties airflow restriction directly to overheating and premature failure:

👉 https://www.epa.gov/indoor-air-quality-iaq

Tony sees this weekly:

“If I see a cracked heat exchanger, 80% of the time the plenum was wrong.”

🌀 4. Consequence #2 — High Static Pressure (ECM Blowers Hate It)

Necking down a plenum raises external static pressure because the blower is trying to shove the same amount of air through a smaller opening.

ECM motors try to compensate by increasing torque — but they do not create infinite airflow.

NREL documentation confirms ECM motors hit a torque ceiling, after which airflow collapses:

👉 https://www.nrel.gov/docs/fy13osti/55636.pdf

High static causes:

-

louder blower noise

-

higher energy consumption

-

reduced CFM

-

shorter blower lifespan

-

coil icing in summer

-

lower heating efficiency

Tony’s rule:

“You want 0.50 inches WC or lower. Neck it down and you’ll be at 0.80–1.00 in a heartbeat.”

🔇 5. Consequence #3 — Noise, Whistling, and Boominess

A forced reduction in plenum size forces air to accelerate.

That high-velocity air:

-

whistles at sheet metal edges

-

rumbles in the coil case

-

resonates in the drop

-

vibrates the cabinet

-

creates “boom-thud” noise at startup

Tony can diagnose a necked-down plenum just by listening to a furnace start.

He says:

“If a furnace sounds like it’s clearing its throat, the plenum is wrong.”

❄️ 6. Consequence #4 — Coil Performance Collapses (Cooling Gets Weak)

A furnace plenum doesn’t just affect heating — it directly affects the coil.

Necked-down plenums cause:

-

low evaporator CFM

-

coil freeze in heat pump or AC mode

-

poor humidity removal

-

low SEER2 efficiency

-

poor register throw

-

uneven cooling

-

warm second floors

Tony’s rule:

“If you build the plenum wrong in winter, you’re guaranteeing a callback in summer.”

🚫 7. Consequence #5 — Two-Stage Furnaces Lose Staging Logic

Two-stage furnaces require stable airflow in BOTH low and high stage.

When airflow is restricted:

In Low Stage

-

furnace thinks it’s undersized

-

prematurely jumps to high stage

-

short cycles

-

noise increases

-

comfort decreases

In High Stage

-

blower hits max torque

-

airflow collapses

-

limit switch trips

-

furnace shuts down

This defeats the entire purpose of a two-stage system.

Tony tells every homeowner:

“If your furnace jumps to high stage in 60 seconds, the plenum is wrong.”

🧱 8. Why Installers Neck Down Furnaces — And Why Tony Never Does

Reason 1: Old ductwork size

Every retrofit job has a legacy plenum that “was always that size.”

Tony’s response:

“Then rebuild it!”

Reason 2: Laziness or rushing

Some techs don’t want to fabricate a proper transition.

Tony says:

“If you can’t make sheet metal, you’re not installing furnaces.”

Reason 3: Misunderstanding ECM blowers

Installers assume ECM motors can overcome restrictions.

They can’t.

Reason 4: Not understanding air velocity

Reducing width increases velocity and pressure.

Reason 5: Bad rules of thumb

“18-inch plenum worked on the old unit — it’ll work now.”

No it won’t.

Modern furnaces push double the air.

📏 9. Tony’s Rules for Proper Plenum Design (Never Break These)

Here is Tony’s exact plenum design process.

✔ Rule 1: Match or Exceed Cabinet Width

A 21” furnace requires a 21-inch wide plenum — minimum.

Tony prefers 22–24 inches to reduce velocity.

✔ Rule 2: Smooth, Tapered Transitions Only

No abrupt changes.

No straight vertical drops.

Tony uses a 4- or 5-sided transition with a taper of:

-

15 degrees per side preferred

-

maximum 30 degrees per side

ASHRAE recommends gentle transitions for low static:

👉 https://www.ashrae.org

✔ Rule 3: No Coil Jammed Tight Against Blower Offset

Leave space.

Let air expand before hitting the coil.

Tony says this prevents coil “hot spots.”

✔ Rule 4: Plenum Height Matters

A good plenum is tall enough to allow even airflow across coil fins.

Tony’s minimum:

At least 10–12 inches above the furnace before the coil.

✔ Rule 5: No “pancake plenums”

Short, wide plenums with no vertical rise cause turbulence.

Tony avoids them like the plague.

✔ Rule 6: Internal Bracing Prevents Oil-Canning

Large plenums should have internal bracing to prevent:

-

popping

-

flexing

-

vibration

✔ Rule 7: Seal Everything

No leaks.

No turbulence from gaps.

No whistling edges.

Tony uses:

-

mastic

-

UL-181 foil tape

-

screws

-

S-cleats and drives

🧰 10. How Tony Fixes a Neck-Down Job (His Field Method)

When Tony sees a bad plenum, here’s what he does:

🔧 Step 1 — Measure Static Pressure

If ESP is over 0.50” WC, airflow is suffering.

🔧 Step 2 — Measure Temperature Rise

Over spec?

Furnace is choking.

🔧 Step 3 — Inspect Coil Case

Hot spots and streaking show airflow imbalance.

🔧 Step 4 — Rebuild Plenum

Tony fabricates:

-

a new plenum box

-

a tapered transition

-

matching cabinet opening

-

new takeoffs

🔧 Step 5 — Retune ECM Blower

Lower torque

Lower RPM

Better comfort

Quieter operation

🔧 Step 6 — Re-test and Document

Tony checks:

-

high stage

-

low stage

-

AC airflow

-

ECM torque

-

ESP

-

temperature rise

When airflow is fixed, everything stabilizes.

🧪 11. Tony’s Diagnostic Signs You Have a Plenum Mismatch

Homeowners usually describe problems like:

-

“The furnace is loud.”

-

“It smells hot.”

-

“It keeps shutting off.”

-

“It blows warm air but the house never heats.”

-

“Upstairs is always cold.”

-

“Air comes out weak.”

-

“The AC doesn’t cool evenly.”

-

“It goes into high stage too fast.”

-

“The blower sounds like a jet engine.”

Tony hears one thing:

“Your plenum is too small.”

🏆 12. Tony’s Perfect Plenum Layout for a 21-Inch Furnace

Here’s the blueprint Tony uses for modern 96% two-stage units:

A. 21–24” wide plenum

Always match or exceed furnace width.

B. 4–5 sided smooth transition

No sudden restriction.

C. 10–14” rise before coil

Allows air to expand evenly.

D. Radius bends or turning vanes

Reduce turbulence.

E. Low-static coil case

Compatible with ECM airflow.

F. Proper takeoff spacing

No bottlenecks.

No clustered branches.

G. Fully sealed with mastic

No whistling.

No leakage.

Improved static pressure.

H. Support structure

No flexing or oil-canning.

Tony says:

“When you build the plenum right, the furnace is quiet, the coil is happy, the airflow is stable, and the homeowner thinks you’re a genius.”

🔥 Final Word from Tony

“Air doesn’t like being squeezed.

Furnaces don’t like high static.

Coils don’t like uneven airflow.

And heat exchangers really don’t like overheating.”

“A 21-inch furnace needs a 21-inch plenum.

Period.

Neck it down and everything goes downhill from there.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: Gas Line Reality Check — The BTU Math That Proves Your 100k Furnace Isn’t Getting Fed