Tony’s No-Excuses Breakdown of Why Most Furnaces Run Starved — And How to Prove It with Nothing But Math

Every winter, Tony walks into homes where the homeowner says:

“My furnace is new, but it won’t heat the house.”

Tony doesn’t check the thermostat first.

He doesn’t look at the flame sensor.

He doesn’t check the filter.

He checks the gas line.

Why?

Because 99% of “weak heat” furnaces aren’t sick — they’re starving.

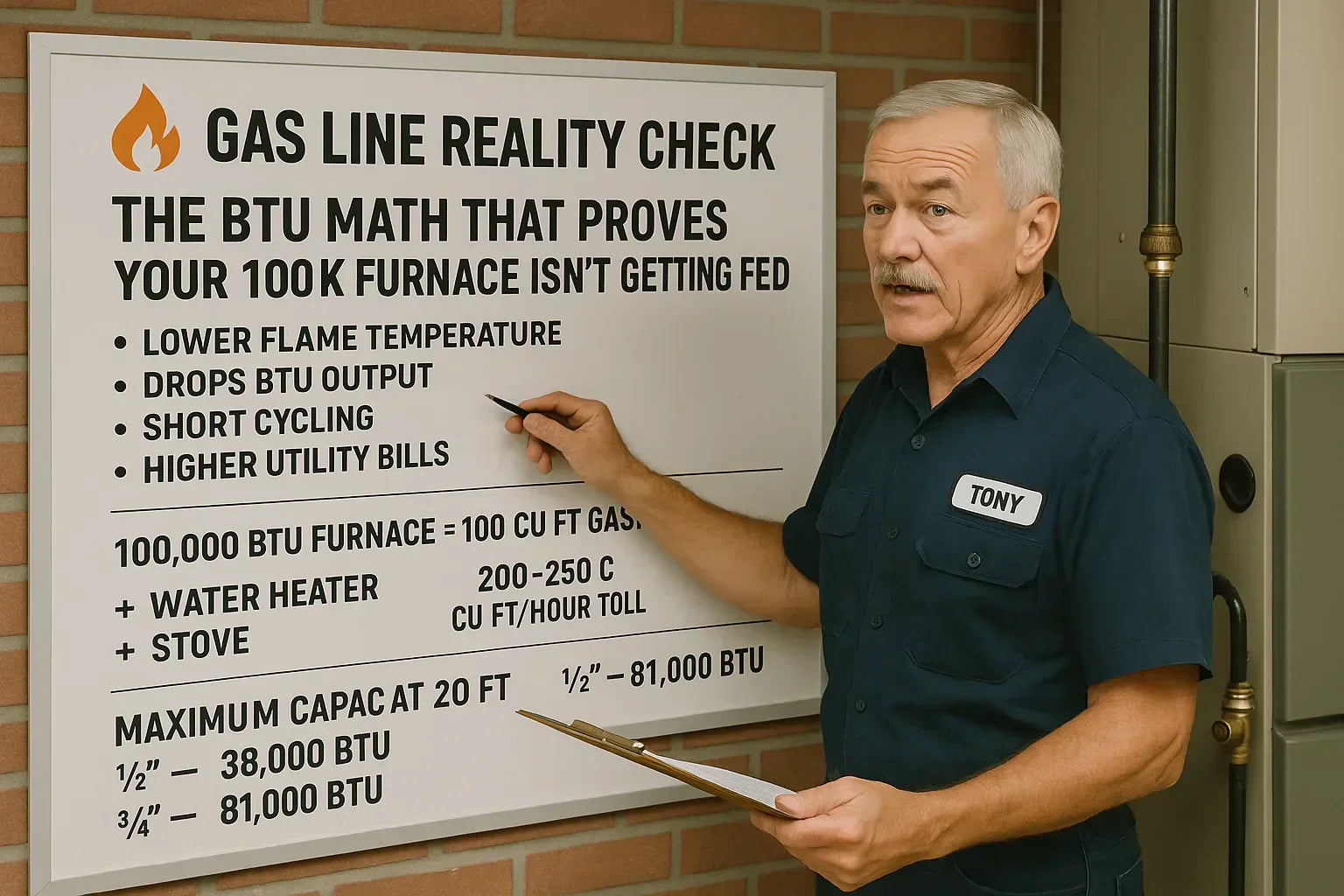

When a 100,000 BTU furnace isn’t getting enough fuel, it:

-

produces lower flame temperature

-

drops total BTU output

-

short cycles

-

overheats the heat exchanger

-

loses efficiency

-

raises utility bills

-

increases CO output

-

never reaches thermostat setpoint

And here’s the punchline:

Most installers don’t size gas lines using actual BTU math.

They run whatever pipe is “already there” and pray it works.

Tony doesn’t pray.

Tony does math.

Let’s break down the real gas sizing rules that prove why your 100k furnace probably isn’t being fed anywhere close to 100k BTU.

100,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T961004CN

📏 1. Gas Pipe Isn’t a Guess — It’s a BTU Highway

Think of a gas line like a highway.

-

BTUs = traffic

-

Pipe diameter = lanes

-

Length = distance

-

Fittings = stop signs

-

Gas meter pressure = pump pressure

If the highway is too small, too long, or has too many turns, traffic slows.

Your furnace doesn’t care about the SIZE of the pipe.

Your furnace cares about how many BTUs actually reach it.

According to the National Fuel Gas Code (NFPA 54)

pipe size, length, and fittings determine gas flow.

Tony’s version:

“If the pipe can’t deliver the BTUs, the furnace can’t make the heat.”

🧮 2. Let’s Do the Math — What a 100k Furnace Actually Needs

A 100,000 BTU furnace needs 100 cubic feet of gas per hour (roughly).

Natural gas contains about 1,000 BTU per cubic foot.

So the furnace needs:

✔ 100 CFH (Cubic Feet per Hour)

PLUS the gas use of every other appliance on the line:

-

water heater (30–40 CFH)

-

stove (50–65 CFH)

-

dryer (22–30 CFH)

-

gas fireplace (20–40 CFH)

-

outdoor grill (20–40 CFH)

Total household gas demand can easily exceed:

🔥 200–250 CFH

… which must ALL travel through the same pipe.

Most homes are built with:

-

a ½” black iron trunk

-

or ½” CSST

-

or mixed legacy pipe

And here’s the reality:

❌ A ½” gas line CANNOT support 200+ CFH

❌ A ½” gas line often cannot even support 100 CFH

Don’t take Tony’s word for it.

Look at the tables.

📉 3. The Gas Line Sizing Charts Don’t Lie — And They Prove You’re Undersized

Here’s the truth from the International Fuel Gas Code (IFGC):

👉 https://codes.iccsafe.org/content/IFGC2021P2/chapter-4-gas-piping-installations

Maximum Capacity of ½” Black Iron at 20 Feet:

➡ 92,000 BTU

That means if:

-

your run is 21 feet

-

or you add one more appliance

-

or the line has elbows

-

or gas pressure is slightly lower

-

or you have an older meter

…your 100k furnace is no longer getting fed.

Tony’s rule:

“A ½-inch line is NEVER acceptable for a 100k furnace on a shared system. Period.”

Now look at CSST (corrugated stainless steel tubing).

Manufacturers like OmegaFlex publish the numbers:

Maximum Capacity of ½” CSST at 20 Feet:

➡ 38,000 BTU

That’s not even enough for a water heater AND a stove, let alone a furnace.

Tony’s version:

“½-inch CSST is a joke. You starve every furnace connected to it.”

🔄 4. The Fittings Kill the Flow — Every Elbow Is a BTU Thief

Installers love to ignore fittings.

They shouldn’t.

Every 90° elbow in a gas line adds “equivalent length,” reducing capacity.

According to NFPA 54:

👉 https://www.nfpa.org

a single 90° elbow = 5 additional feet of pipe length.

A gas line with:

-

4 elbows

-

25 feet of pipe

…acts like a 45-foot run, not 25.

And the chart capacity PLUMMETS at longer lengths.

Tony says:

“Every elbow is a choke point. A long run full of elbows is a gas starvation machine.”

🧪 5. Real-World Example — Why a 100k Furnace Is Only Producing 70–80k BTU

Tony uses this example constantly when training:

The house has:

-

½” black iron

-

35-foot run

-

3 elbows

-

water heater

-

stove

Effective length:

35 + (3 × 5) = 50 feet

½” pipe at 50 feet can carry:

➡ 64,000 BTU

But the furnace needs:

➡ 100,000 BTU

So the furnace is running at:

➡ 64% of rated output

This is why homeowners say:

-

“The air is warm, not hot.”

-

“It runs constantly.”

-

“The furnace never reaches the setpoint.”

-

“My gas bill doubled after installing a HIGHER-efficiency furnace.”

Tony’s brutal conclusion:

“You bought a 100k furnace, but you’re only feeding it like a 60k.”

📉 6. Flame Behavior Doesn’t Lie — Starved Furnaces Look Sick

Tony reads flame the way a mechanic reads engine noise.

A starved furnace flame:

-

is tiny

-

is weak blue

-

flickers

-

pulls toward the burner

-

doesn’t “roar”

-

has uneven cones

-

leans or rolls

-

sometimes lifts off the burner

-

may cause delayed ignition

EPA documentation confirms that low-gas conditions lead to incomplete combustion and CO production:

👉 https://www.epa.gov/indoor-air-quality-iaq

Tony’s rule:

“If the flame looks weak, the gas line IS weak.”

🔥 7. Clock Your Meter — The Math That Exposes Undersizing

No tool proves undersizing faster than the meter clock test.

Tony does this on every furnace startup.

Step 1: Turn off all other gas appliances.

Step 2: Run furnace on high fire.

Step 3: Time the smallest dial on the meter (usually ½ cubic foot).

Step 4: Do the math:

CFH = (3600 ÷ seconds per revolution) × dial size.

If you get:

-

100 CFH → Furnace is getting full fuel

-

80 CFH → Furnace is 20% starved

-

60 CFH → Furnace is 40% starved

-

50 CFH → Furnace is half its rating

Tony’s truth:

“The meter never lies.

If the math says you’re starving, you’re starving.”

⚡ 8. Low Gas Pressure = Low BTUs = Low Heat

Most furnaces need:

✔ 3.5 inches WC manifold pressure for natural gas

✔ 10–11 inches WC supply pressure for propane

But starved gas lines often deliver:

-

2.8"

-

2.5"

-

even 1.9" at high fire

NFPA 54 states minimum pressures required for proper combustion:

👉 https://www.nfpa.org

Tony’s version:

“If your manifold pressure drops when the furnace hits high stage, your gas line is garbage.”

🚫 9. Two-Stage Furnaces Suffer the Worst (Because Low Stage Hides the Problem)

In low stage, a furnace only needs ~65% of its gas input.

So gas starvation often hides in plain sight for years.

But when high stage kicks in?

-

flame lifts

-

blower ramps

-

manifold pressure drops

-

furnace trips

-

limit switch opens

-

system short-cycles

Tony’s rule:

“Never size a gas line for low stage.

Size it for high stage — that’s where the problems live.”

🧰 10. How Tony Fixes an Undersized Gas Line (The Real Solutions)

Here are Tony’s correction methods, in order:

✔ 1. Upsize the entire run

-

Replace ½” with ¾” black iron

-

Or run a 1” trunk for multiple appliances

✔ 2. Run a dedicated gas line to the furnace

The BEST solution.

✔ 3. Switch to 2 psi gas with regulators (if local code allows)

Massive capacity increase.

✔ 4. Reduce unnecessary elbows

Every elbow removed increases BTU flow.

✔ 5. Remove appliance bottlenecks

Old shutoff valves

Flexible connector kinks

Undersized drip legs

✔ 6. Verify meter capacity

Tony checks the gas company’s meter charts.

If the meter is too small?

The entire home starves.

Most meters only support 150–250k BTU.

A furnace + water heater + stove already exceed that.

🧨 11. The “Tony Standard” — Gas Lines That NEVER Starve Furnaces

Tony oversizes every gas line because:

-

gas is cheap

-

BTU loss is expensive

-

callbacks kill profit

Here’s Tony’s standard:

✔ 1” main trunk

✔ ¾” branch to furnace

✔ ¾” to water heater

✔ ½” only for minor loads like small gas logs

Tony explains:

“Oversizing a gas line costs $30 more.

Starving a furnace costs thousands over its lifetime.”

🔥 Final Word from Tony

“Gas lines don’t care about what size pipe you think works.

They only care about BTU math.

If the math says you’re starving your furnace — YOU ARE.

A furnace that doesn’t get enough fuel can’t heat right, can’t burn clean, and won’t live long.

So stop guessing.

Do the math.

Feed the furnace.

Or don’t install one at all.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: Why Tony Always Rebuilds the Return Drop on a Two-Stage Furnace Install