The Real-World Condensate Rules That Separate Clean Installs from Catastrophes

A high-efficiency furnace is a wonderful machine — quiet, efficient, and engineered to squeeze every last BTU out of your gas bill.

But it comes with a catch:

It makes water. Lots of it.

A 96% AFUE furnace like the Goodman GR9T961004CN can produce ½ to 1 gallon of water per hour on a cold day.

In an improperly pitched or poorly drained system?

That water ends up in the:

-

blower compartment

-

secondary heat exchanger

-

inducer housing

-

furnace cabinet

-

basement floor

-

drywall

-

safety pan

-

drain overflow

-

electrical controls

-

homeowner’s patience

Tony has been called to hundreds of homes where the furnace wasn’t broken —

the condensate system was.

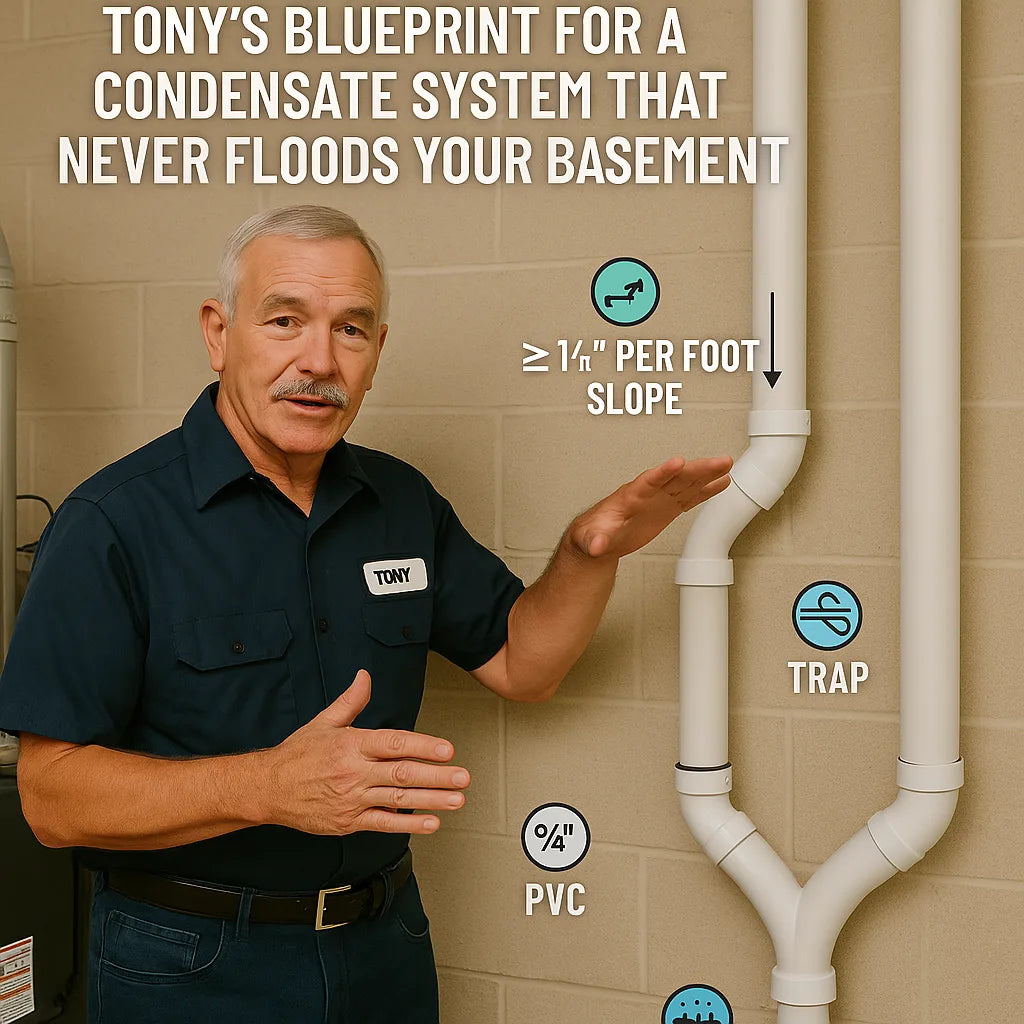

Today you’re getting Tony’s complete blueprint for condensate management: slope, pitch, line sizing, trap design, neutralizers, terminations, freeze protection, and the exact do/don’t list Tony trains apprentices with.

If you follow this blueprint, your furnace will never flood your basement — ever.

🧊 1. The #1 Mistake Installers Make: Forgetting the Furnace Makes Water

Most techs treat condensate as an afterthought.

Tony doesn’t.

Tony’s rule:

“If the furnace is high-efficiency, the condensate system is as important as the gas line.”

Here’s the truth:

A condensing furnace creates water because:

-

Flue gases are cooled below dew point

-

Water vapor condenses

-

Acids form (carbonic, nitric)

-

Condensate must be drained properly to avoid corrosion

DOE documentation warns that improper drainage leads to furnace failure and water damage:

👉 https://www.energy.gov/energysaver/furnaces-and-boilers

Tony has a simpler version:

“Water always wins. If you don’t control it, it controls you.”

📐 2. The Golden Rule: ¼” Per Foot Slope — But Tony Doesn’t Stop There

Every codebook, manufacturer, and training module tells you the same thing:

✔ Condensate lines must slope ¼ inch per foot (2%)

toward the drain

Never away.

Never flat.

Never sagging.

This rule is backed by:

-

International Mechanical Code (IMC)

👉 https://codes.iccsafe.org

But here’s where Tony differs:

Tony’s Slope Rule

He wants ⅜” per foot when possible.

Why?

Because over time, the line:

-

sags

-

moves

-

expands

-

contracts

-

fills with bio-gunk

-

vibrates

-

warms and cools

Extra slope prevents:

-

blockages

-

backups

-

freeze-ups

-

standing water

Tony says:

“The book says ¼.

The field says ⅜.

Listen to the field.”

🔁 3. The Trap — The Most Misunderstood Part of the System

Nearly every flooded furnace Tony sees has one of these three problems:

❌ No trap

❌ Wrong trap

❌ Trap installed backwards

A condensing furnace has negative pressure on its drain outlet.

Without a trap, the inducer will pull air back up the drain, sucking sewer gas and preventing drainage.

Tony’s Trap Requirements

-

Must match manufacturer spec

-

Must be deep enough to counter negative pressure

-

Must be installed upright, not sideways

-

Must be accessible for cleaning

-

Must not be homemade from copper elbows or PVC art projects

Goodman, Carrier, Rheem, and Trane ALL specify trap geometry for a reason.

EPA documentation confirms traps prevent cross-contamination and air intrusion:

👉 https://www.epa.gov/indoor-air-quality-iaq

Tony’s rule:

“If the trap isn’t correct, nothing downstream matters.”

🧰 4. Line Sizing — Why ½” PVC is a Guaranteed Callback

Installers love ½” PVC because:

-

it’s cheap

-

it’s small

-

it’s easy to run

-

it “looks clean”

But ½" PVC is not approved in most mechanical codes for condensate drains.

It clogs instantly.

Biofilm grows inside.

Slime builds.

Water backs up.

Tony’s Minimum Line Sizes

-

¾" PVC for single furnace

-

1” PVC for long runs

-

1¼” PVC for multiple-unit drains

ASHRAE condensate guidelines recommend larger-diameter drains to prevent buildup:

👉 https://www.ashrae.org/technical-resources

Tony’s rule:

“If the line looks small, it is too small.”

🧼 5. Cleanouts, Access, and Unions — The Three Things Cheap Installs Skip

A condensate line WILL eventually:

-

clog

-

slime

-

freeze

-

build algae

-

collect lint and debris

Tony’s installs always include:

✔ A cleanout tee

✔ A union near the trap

✔ A secondary access port

Why?

Because maintenance matters.

Tony says:

“If I can’t flush it, I’m not installing it.”

⚠️ 6. The Condensate Pump — Friend, Enemy, or Both?

Tony doesn’t hate pumps.

He hates pumps installed badly.

Pumps fail when:

-

lines lack slope before the pump

-

check valve sticks

-

pump vibrates off-level

-

tubing is too small

-

pump is not isolated

-

float switch is wired wrong

-

pump is used as a band-aid instead of fixing slope

Tony’s Condensate Pump Rules

-

Use only when gravity isn’t an option

-

Isolate with rubber feet or pad

-

Install a secondary high-level switch

-

Use clear vinyl tubing only if short run — PVC preferred for long runs

-

Test the pump every season

Never trust a pump alone.

Tony says:

“If gravity can do the job, don’t invite a pump to the party.”

🧊 7. Freeze Protection — The Problem Installers Forget Until January

Condensate lines often run through:

-

crawl spaces

-

attics

-

unconditioned basements

-

exterior walls

And what happens when that line freezes?

✔ Inducer fills with water

✔ Furnace lockout

✔ Basement flood

✔ Water in heat exchanger

Tony’s Freeze Rules

-

NEVER run condensate outside without heat tape

-

Insulate PVC with closed-cell insulation

-

Keep lines away from cold exterior walls

-

Add a heat trace cable when needed

-

Avoid long outdoor runs — terminate inside when possible

EPA warns that winter freeze-ups are a major cause of condensate backups and furnace failures:

👉 https://www.epa.gov

Tony’s rule:

“Frozen water expands. Expanding water destroys everything.”

🧱 8. Termination: Where the Water Ends Up Matters

Tony checks every termination.

Where does the condensate go?

Good endings:

✔ floor drain

✔ laundry standpipe

✔ approved sump

✔ utility sink

✔ exterior termination with freeze protection

✔ approved condensate pump to drain

Bad endings Tony sees:

❌ bucket

❌ garden hose coiled on basement floor

❌ drywall cavity

❌ outside wall with no slope

❌ sump pump discharge pipe

❌ sewer line without proper trap

Code requires proper drainage:

👉 International Plumbing Code: https://codes.iccsafe.org

Tony has his own version:

“If the drain termination looks stupid, it’ll fail. If it looks smart, it’ll last.”

🔥 9. Neutralizers — Required When Draining Into Certain Systems

Condensate from a gas furnace is acidic.

Not dangerous to touch — but damaging long-term to:

-

cast iron drains

-

copper drains

-

septic systems

-

pump impellers

-

floor surfaces

ASHRAE and EPA both document the need for neutralizers in many installations:

👉 https://www.ashrae.org/technical-resources

👉 https://www.epa.gov

Tony installs neutralizers when:

-

draining into septic

-

draining into cast iron stack

-

draining through long PVC systems

-

water is leaving the house through concrete slab

Tony’s rule:

“If the drain is metal or the homeowner has septic, neutralize it.”

🔍 10. Tony’s 10-Minute Condensate Inspection Checklist

This is what Tony checks every time he walks into a new furnace installation:

✔ 1. Is slope correct from end to end?

Start to finish — without sags.

✔ 2. Is the trap installed exactly as manufacturer requires?

Not close. Not modified. Not sideways.

✔ 3. Is the line at least ¾"?

If not → replacement needed.

✔ 4. Are there cleanouts?

If not → future clog guaranteed.

✔ 5. Does the pump sit level and isolated?

If not → noise, failure, vibration.

✔ 6. Does the termination make sense?

If not → redesign required.

✔ 7. Are outdoor sections insulated?

If not → freeze-up guaranteed.

✔ 8. Is the furnace level?

If the furnace is out of level, condensate pools inside the heat exchanger.

✔ 9. Are there dips in the line?

Any sag = future water pocket.

✔ 10. Is the furnace cabinet clean inside?

Water marks = a past or active drain failure.

🧨 11. Tony’s Most Common Field Horror Stories (All Caused by Bad Drainage)

Tony has seen:

💀 A furnace rusted through the secondary heat exchanger

Due to condensate pooling.

$2400 mistake.

💀 A flooded basement caused by an untrapped drain

60 gallons of water on the floor.

💀 A furnace shorted out because water dripped onto the control board

$800 repair.

💀 A backward trap sucking sewer gas into the home

CO and methane exposure.

💀 A condensate pump spraying water onto a finished wall

Mold behind drywall.

Tony says:

“Every flooded basement starts with someone ignoring slope, pitch, or drainage.”

🏆 12. The Perfect Condensate Setup — Tony’s Gold Standard

Here’s what a perfect Tony-approved condensate system looks like:

A. ⅜” Per Foot Slope (Minimum ¼”)

Every inch of pipe slopes toward the drain.

B. Factory-Spec Trap

Accessible

Correct height

Installed upright

Cleanable

C. ¾" or 1" PVC

No exceptions.

D. Cleanouts & Union

At trap

At long runs

Near pump (if used)

E. Insulated Lines in Cold Spaces

Closed-cell insulation

Heat trace if needed

F. Smart Termination

To an approved drain

No uphill runs

No long exterior lines

G. Optional Neutralizer

For septic or cast iron

H. Pump Only When Necessary

Tested regularly

Wired to safety float

I. Furnace Level to 1°

Critical for proper internal drainage

J. No Sagging Lines

PVC clamps every 3–4 feet

Tony’s conclusion:

“A perfect condensate setup is invisible.

It never makes noise.

It never backs up.

And it never floods your house.”

🔥 Final Word from Tony

“High-efficiency furnaces don’t fail because of heat.

They fail because of water.

If you don’t respect slope, pitch, and drainage, you’re begging for a callback — or a disaster.”

“But if you build the condensate system right?

That furnace will run clean for 20 years without a single puddle.”

Buy this on Amazon at: https://amzn.to/48LE6e5

In the next topic you will know more about: The Cabinet-to-Plenum Mismatch — Why Tony Refuses to ‘Neck Down’ a 21-Inch Furnace