🧩 1️⃣ The Forgotten Half of System Sizing

“You could spend top dollar on a Goodman high-efficiency furnace, but if your ducts are leaking, you’re basically paying to heat your crawlspace.”

Every homeowner thinks system sizing starts and ends with the furnace BTUs. But here’s the truth — your ductwork is half the system.

Without efficient air delivery, all the precision of Manual J sizing goes out the window — literally.

Ductwork efficiency measures how much of your conditioned air actually makes it to the living space. According to Energy Star, the average home loses 20 to 30 percent of its heating and cooling energy through leaky or poorly designed ducts.

So even if you install a perfectly sized 80,000 BTU Goodman furnace, leaks and pressure issues can make it perform like a 60,000 BTU unit.

That’s why pros pair Manual J (load calculation) with Manual D (duct design).

Manual J chooses the engine; Manual D makes sure the transmission delivers the power.

Tony’s Rule: “Manual J picks the engine. Manual D makes sure the tires touch the road.”

📏 2️⃣ Why Airflow and Pressure Matter More Than You Think

Airflow is the lifeblood of your HVAC system, and static pressure is its blood pressure. Too high? The blower strains. Too low? You starve the system.

When air moves through your ducts, friction and restriction build pressure. If your ducts are too small, every bend and joint resists that airflow, forcing the blower motor to push harder and louder.

Proper design keeps static pressure between 0.3–0.8 inches WC (water column), depending on the furnace and layout. Exceed that, and efficiency plummets.

ACCA’s Manual D guide sets clear formulas for calculating pressure losses based on duct length, turns, and materials — exactly what many “rule-of-thumb” installers skip.

Tony’s Tip: “A furnace doesn’t push air — it pressurizes it. The ducts decide whether it ever gets where it’s supposed to.”

🏠 3️⃣ Leaks, Gaps & Bends — Where Efficiency Dies

Take a stroll through most attics and you’ll find the usual suspects:

-

Loose foil tape peeling off joints

-

Crushed flex duct snaked around rafters

-

Bare metal trunks sweating in summer

-

Sharp elbows turning airflow into turbulence

Each problem chips away at efficiency. Every 90-degree bend equals about 10 feet of straight-duct resistance. And leaks? They’re worse.

Hot air that escapes into an unconditioned attic doesn’t just waste energy — it upsets system balance. Bedrooms at the far end of the duct run become freezing zones, while the hallway feels like the equator.

That’s why sealing matters. The U.S. EPA’s duct efficiency tips recommend mastic sealant over regular duct tape (which dries out and fails within a year). Add insulation to attic or crawlspace ducts, and you stop even more heat loss.

Tony’s Note: “That attic flex duct that looks like it was installed by a pretzel factory? Yeah, that’s why your master bedroom never hits 70 degrees.”

🧮 4️⃣ How Duct Loss Skews Furnace Sizing

When ducts leak or restrict, your Manual J math becomes useless. Here’s a simple example:

| Furnace Rated Output | Duct Efficiency | BTUs Delivered |

|---|---|---|

| 80,000 BTU | 100 % | 80,000 BTU |

| 80,000 BTU | 85 % | 68,000 BTU |

| 80,000 BTU | 75 % | 60,000 BTU |

So a brand-new 96 AFUE Goodman furnace might deliver only 60,000 usable BTUs if 25 percent of airflow never reaches the rooms.

That’s why some techs upsize the furnace “just in case.” But oversizing is a Band-Aid — it causes short cycling and higher bills. Fixing the ducts always beats brute force.

Tony’s Line: “You don’t cure a bad straw by buying a bigger milkshake.”

🔍 5️⃣ Testing & Balancing — The Pro’s Edge

A real HVAC pro tests, not guesses.

🔹 Airflow Testing

Using a manometer or flow hood, technicians measure the actual CFM (cubic feet per minute) coming from each supply register. If your living room only gets 60 CFM when it needs 100, comfort will suffer.

🔹 Static Pressure Testing

They’ll also check the return and supply sides with small probes. High readings signal duct restriction, dirty filters, or undersized runs.

🔹 Duct Leakage Test

A Duct Blaster pressurizes the system to locate and quantify leaks. Energy-efficiency programs often require this test before rebates.

Target: Total system leakage under 10 percent.

See Energy.gov’s duct testing overview for how audits work.

Tony’s Advice: “If your installer doesn’t own a manometer, they’re not sizing — they’re guessing.”

⚙️ 6️⃣ Duct Design 101 — What Manual D Does for You

Manual D is the science of turning your load calculation into actual airflow.

Step 1: Import each room’s BTU demand from Manual J.

Step 2: Determine required CFM for that space (1 CFM ≈ 1.08 × BTUs / ΔT).

Step 3: Choose duct sizes and materials to deliver that airflow within acceptable friction limits.

Step 4: Balance the system with dampers and return paths.

The goal: every register gets the right airflow, and total static pressure stays within manufacturer specs.

Even the most efficient furnaces — like the Goodman 96 AFUE 80 000 BTU model — depend on this balance to achieve real-world efficiency.

Tony’s Quote: “Manual D is the reason your system hums instead of howls.”

💸 7️⃣ The Real Cost of Ignoring Duct Efficiency

If your ducts are leaking or unbalanced, your wallet feels it first.

💰 Higher Energy Bills

Losing 25 percent of airflow equals roughly 25 percent more gas burned every winter. That’s hundreds of dollars gone each year.

🌡️ Uneven Comfort

Ever notice one bedroom that’s an icebox while the hallway roasts? That’s duct imbalance.

🔇 Noise and Wear

Undersized ducts cause “whooshing” vents and blower strain, shortening motor life.

🧰 Frequent Repairs

Heat exchangers overheat when airflow’s restricted, tripping safety limits and triggering service calls.

Tony’s Warning: “Your furnace shouldn’t sound like it’s bench-pressing air just to heat your living room.”

🧰 8️⃣ Fixing Duct Inefficiency — Tony’s Proven Checklist

| ✅ Step | 🔧 Action | 💡 Why It Matters |

|---|---|---|

| Inspect visible ducts | Look for splits, loose joints, crushed runs | Find where efficiency disappears |

| Seal with mastic (not tape) | Brush-on mastic lasts 10+ years | Prevents re-leaks |

| Add insulation wraps | Especially attic or crawlspace ducts | Stops heat loss and condensation |

| Balance registers | Adjust dampers for even delivery | Keeps rooms within 2–3°F difference |

| Verify return paths | Every room needs return airflow | Prevents pressure imbalances |

| Measure static pressure | Compare to manufacturer specs | Confirms healthy blower operation |

Most of these fixes take hours, not days — and the payoff is immediate: quieter airflow, faster heating, and lower bills.

Tony’s Final Tip: “Every CFM counts. The best furnace in the world can’t fix bad airflow.”

🌎 9️⃣ Why Ductwork Efficiency = Sustainable Heating

Every BTU saved is a BTU you didn’t have to burn. Efficient ducts reduce:

-

Fuel use (less run-time)

-

Greenhouse gas emissions

-

System wear and tear

That’s why modern energy codes now require duct testing for new homes and retrofits. It’s one of the cheapest ways to cut residential carbon output.

For more insight, see Energy Star’s Efficient Duct Design overview.

Tony’s Note: “Going green doesn’t start with solar panels — it starts with sealing what you already own.”

🧾 🔟 The Math of Delivered Efficiency

You can estimate your delivered efficiency this way:

Example:

-

Furnace = 96 AFUE

-

Duct Efficiency = 75 %

-

Delivered Efficiency = 0.96 × 0.75 = 72 %

So a 96 AFUE furnace with bad ducts performs like a 72 AFUE model.

That’s thousands in lost efficiency you already paid for.

Tony’s Advice: “If you’re proud of your high-efficiency furnace, make sure your ducts didn’t bring it back to the 1990s.”

🧠 11️⃣ The Duct–Sizing Connection

Ever wonder why some installers oversize systems? It’s usually because they know the ducts can’t deliver the airflow the Manual J load requires.

In other words:

Poor ducts → Fake Sizing → Wasted Money.

A proper Manual D design fixes airflow issues so you can choose a furnace based purely on your load, not your leaks.

That’s why pros always inspect ducts before finalizing system size.

If the ducts are bad, fix them — don’t oversize the furnace to compensate.

🏁 12️⃣ Tony’s Bottom Line — “Don’t Just Size the Furnace, Size the System”

“Your furnace is only as smart as the ducts feeding it.

If airflow’s off, your sizing math’s off.

Fix the ducts, balance the pressure, then size your system — that’s how you get quiet, efficient comfort.”

Key Takeaways:

-

Duct losses of 20–30 % are common — and expensive.

-

Manual D ensures proper airflow, pressure, and comfort.

-

Sealing and insulating ducts often deliver faster ROI than upgrading equipment.

-

The Goodman 96 AFUE 80 k furnace reaches full potential only when ducts do their part.

CTA:

👉 Before you replace your furnace, have your ducts inspected and sealed. Then size your system with confidence using Goodman’s high-efficiency lineup.

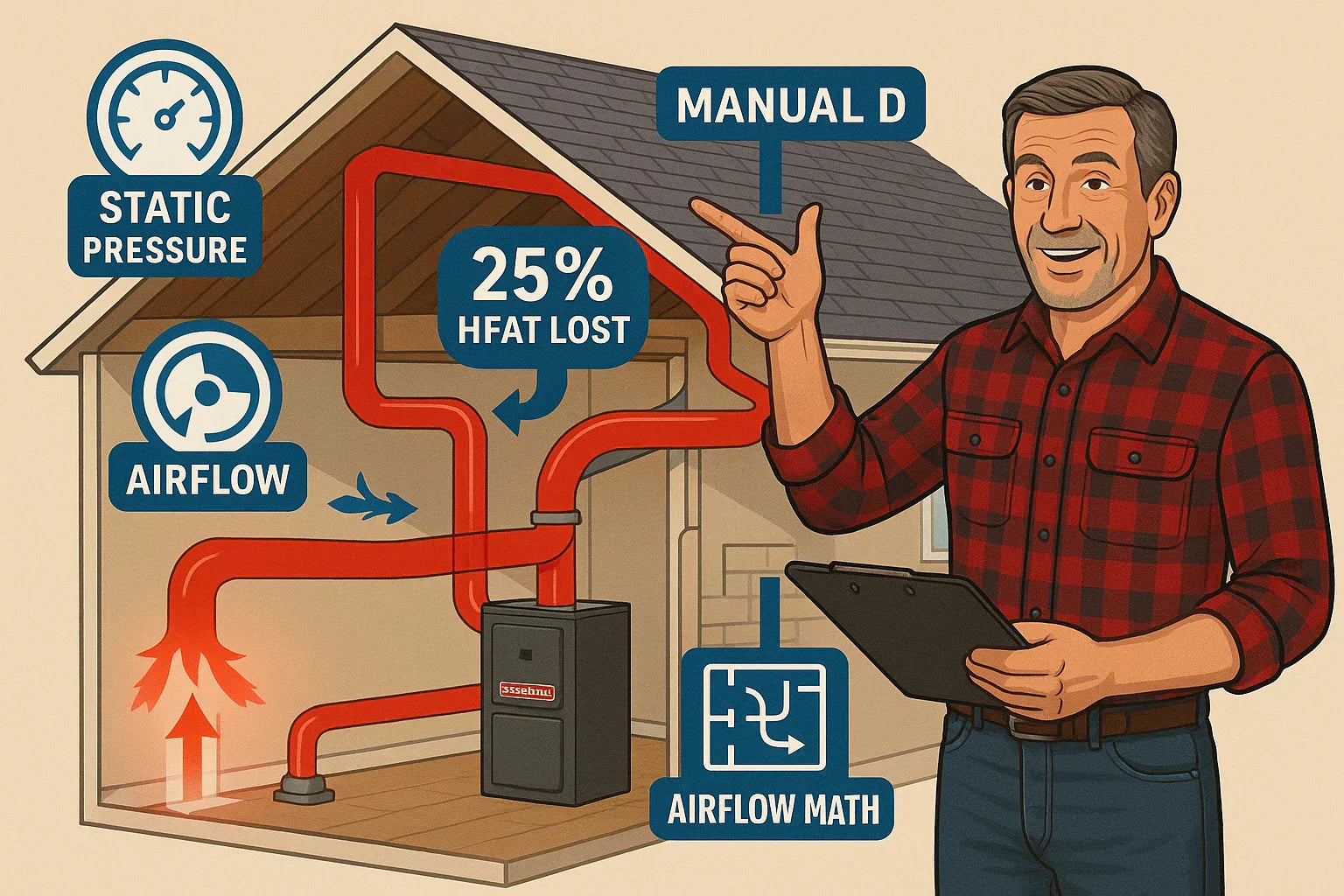

🖼️ Hero Visual Concept (for Designer)

A cutaway of a single-story home showing glowing red ducts delivering heat. Some ducts have blue “leak” arrows escaping into the attic with text “25 % Heat Lost.”

Tony stands beside the system pointing to a gauge labeled Static Pressure 0.5 in WC and a tag that reads Manual D = Airflow Math.

Color theme: Goodman red + charcoal gray + light blue for contrast.

Final Word from Tony:

“Everyone loves talking BTUs and efficiency ratings, but nobody talks about airflow. That’s why most systems never hit their potential. Ductwork isn’t the background — it’s the backbone. Seal it, size it, and your Goodman will reward you every season.”

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: The Sizing Cheat Sheet: BTU Per Square Foot by Region