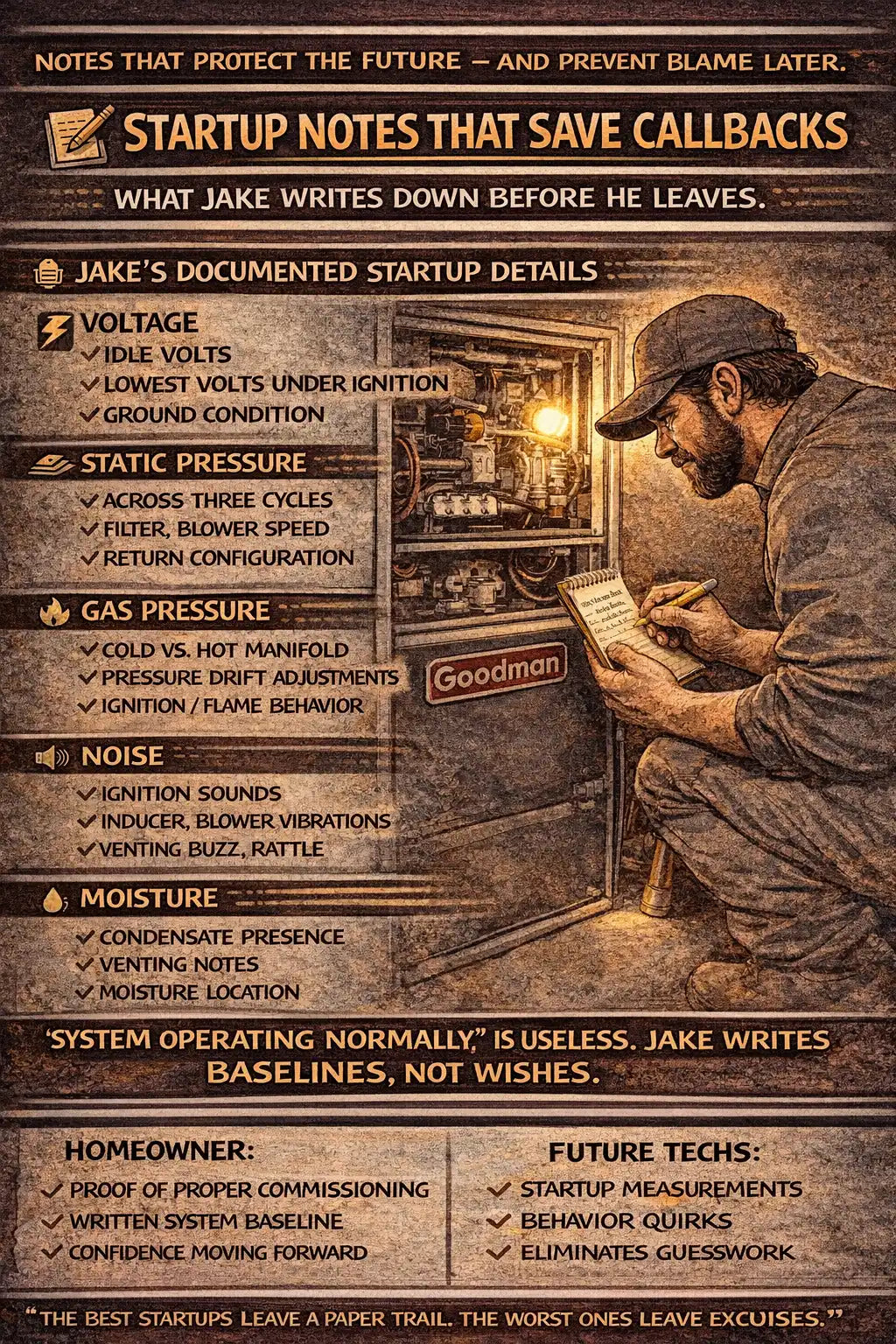

What Jake Writes Down Before He Leaves

Jake doesn’t leave a startup thinking about how well the furnace ran.

He leaves thinking about what will be remembered six months from now — by the homeowner, the next tech, and the furnace itself.

That’s why Jake documents startup like an incident report.

Not because he likes paperwork.

Because memory is unreliable and blame is lazy.

Most callbacks don’t happen because something failed overnight. They happen because no one wrote down what normal looked like on day one.

This article explains exactly what Jake documents before he leaves, why each note matters, and how good startup documentation turns future problems into fast fixes instead of finger-pointing — especially on furnaces like the Goodman GR9S800803BN.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🧠 Why Startup Notes Matter More Than Startup Tools

Tools diagnose the present.

Notes protect the future.

When a furnace acts up months later, the first questions are always:

-

“Did it do this before?”

-

“Was it always like that?”

-

“Is this new?”

Without startup notes, those questions become arguments.

“If it’s not written down, it didn’t happen — and you’ll be blamed.”

Jake writes so he doesn’t have to explain himself later.

📋 Jake’s Rule: Write What Changes, Not Just What Works

Jake doesn’t document perfection.

He documents behavior.

That includes:

-

What stayed consistent

-

What shifted across cycles

-

What was borderline but acceptable

-

What was corrected and why

These notes become the furnace’s origin story.

🔁 Cycle-Based Notes: Why Jake Separates Data by Run

Jake never writes one set of numbers.

He labels:

-

Cycle One

-

Cycle Two

-

Cycle Three

Why?

Because changes across cycles reveal:

-

Voltage instability

-

Gas pressure drift

-

Airflow adaptation

-

Control board learning

A single “final” number hides that story.

Jake writes the story.

⚡ Voltage Notes: What Jake Always Records

Voltage causes more phantom failures than any part.

Jake records:

-

Idle voltage

-

Lowest voltage under ignition load

-

Circuit type (dedicated or shared)

-

Ground condition observations

These notes explain:

-

Future igniter failures

-

Random lockouts

-

Board sensitivity issues

This aligns with industry best practices for diagnosing electrical HVAC issues

(HVAC School – Voltage Drop Basics).

🌬️ Airflow & Static Pressure Notes: Numbers With Context

Jake never writes static pressure alone.

He adds:

-

Filter type and size

-

Blower speed setting

-

Return configuration notes

-

Any audible airflow issues

Why?

Because static pressure without context gets misinterpreted later.

ACCA airflow guidance emphasizes documentation of system conditions, not just readings

(ACCA Manual D Overview).

🔥 Combustion & Gas Notes: What the Flame Said

Jake documents:

-

Ignition timing behavior

-

Flame stability

-

Cold vs. hot manifold pressure

-

Any pressure drift adjustments

He also writes why adjustments were made.

This protects against:

-

“Who touched the gas?”

-

“Was it always like this?”

-

“Did someone misadjust it?”

Manufacturer guidance consistently stresses documenting final operating conditions

(Goodman Furnace Technical Information).

🔊 Noise Notes: Because Sound Is Evidence

Jake writes down noises — even if they’re minor.

He notes:

-

Ignition sounds

-

Inducer pitch

-

Blower ramp noise

-

Cabinet vibration points

Why?

Because noise complaints are subjective — unless documented early.

ASHRAE recognizes early noise documentation as a diagnostic aid for future mechanical issues

(ASHRAE – HVAC Noise & Vibration).

💧 Moisture Observations: Presence or Absence Matters

Jake always records:

-

Any startup moisture

-

Exact location

-

Whether it persisted or disappeared

-

Venting configuration notes

Even if moisture resolves, the note stays.

Why?

Because moisture that disappears can still cause corrosion later.

NFPA venting standards emphasize moisture as a key indicator of venting issues

(NFPA 54 – National Fuel Gas Code).

🧠 Control Behavior Notes: What the Board Learned

Jake documents:

-

Any retries

-

Any delays

-

Any unusual timing

-

Whether behavior was consistent across cycles

Control boards remember patterns.

Jake makes sure the right patterns are recorded.

🧾 What Jake Hands Off (And What He Keeps)

Jake’s notes serve two purposes:

For the Homeowner:

-

Proof of proper commissioning

-

Confidence the system was fully tested

-

Transparency without technical overload

For Future Techs:

-

Baseline data

-

Known quirks

-

Eliminated guesswork

Jake doesn’t overshare — he documents intelligently.

🚫 The Three Documentation Mistakes Jake Sees Most

❌ Mistake #1: Writing only “system operating normally”

That sentence is useless later.

❌ Mistake #2: Recording numbers without conditions

Context matters more than digits.

❌ Mistake #3: Trusting memory over notes

Memory always loses.

🧠 Why Notes Turn Callbacks Into 10-Minute Fixes

With good startup notes:

-

Problems are identified faster

-

Blame disappears

-

Repeat visits shorten

-

Trust increases

Without them:

-

Everything is a mystery

-

Everyone argues

-

Time gets wasted

“Callbacks aren’t expensive because of labor.

They’re expensive because of confusion.”

Jake writes to eliminate confusion.

🏁 Jake’s Final Word on Startup Notes

Startup isn’t finished when the furnace runs.

It’s finished when someone else can understand what you saw.

Jake doesn’t document to cover himself.

He documents to tell the truth later — when it matters.

“The best startups leave a paper trail.

The worst ones leave excuses.”

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: The First Flame Tells the Truth: How Jake Reads Combustion Before the Thermostat Ever Cycles