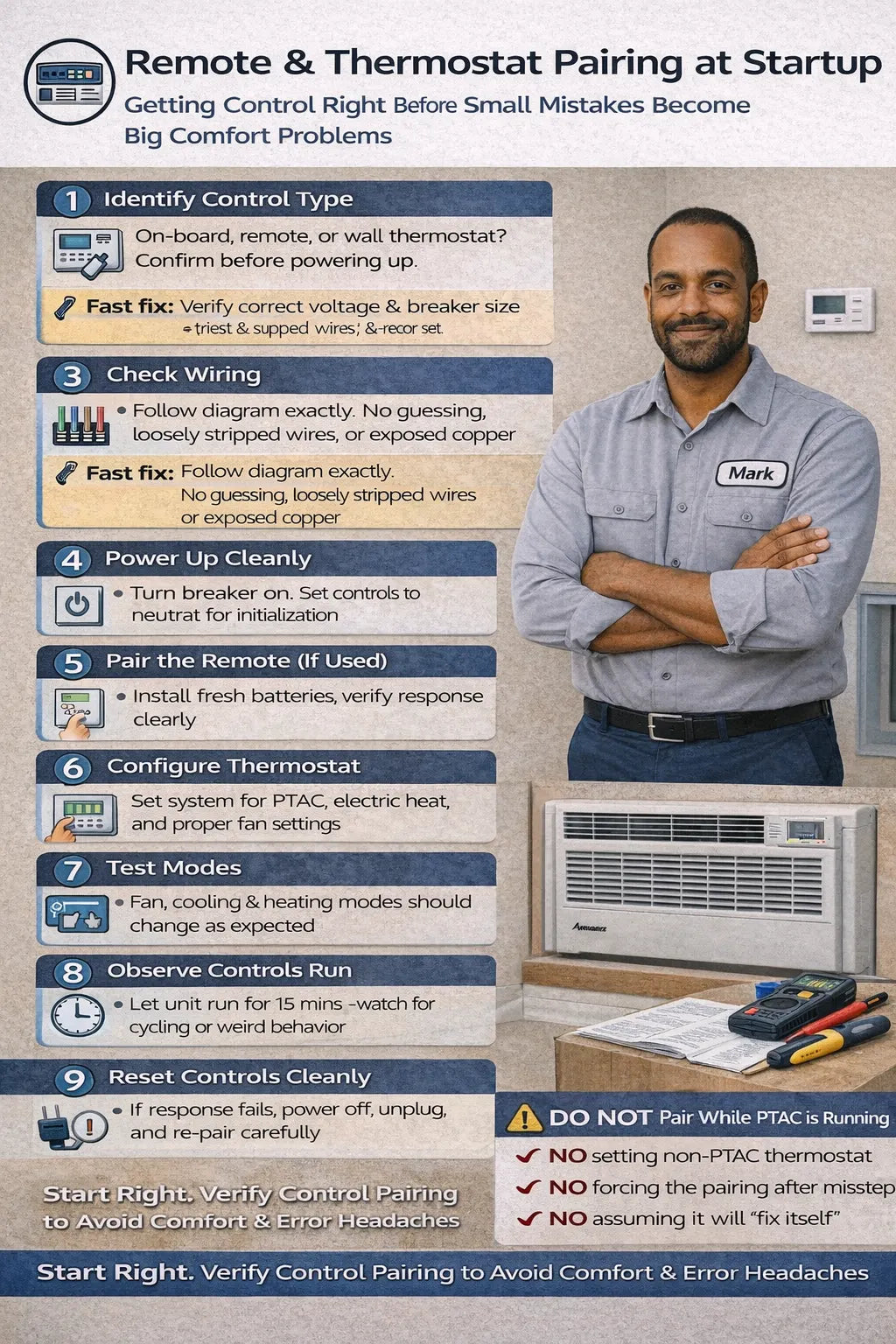

Getting Control Right Before Small Mistakes Become Big Comfort Problems

When a PTAC doesn’t heat or cool the way it should, most people blame the unit itself. In reality, a huge percentage of early PTAC issues trace back to control setup—specifically how the remote or thermostat was paired during startup.

Controls are the brain of the system. If that brain is confused, miswired, or mismatched, even a perfectly installed Amana PTAC will behave unpredictably.

This guide walks through how to properly pair and verify remotes and thermostats during startup, using the Amana J-Series 15,000 BTU PTAC with 3.5 kW electric heat as our reference. The goal is simple: make sure the unit responds exactly the way you expect it to—right from day one.

🧠 Why Control Pairing Matters During Startup

Startup is the only time when:

-

The PTAC is learning its operating environment

-

Controls are first communicating with the board

-

Sensor baselines are established

If pairing is done incorrectly—or rushed—the unit may:

-

Ignore commands

-

Short cycle

-

Heat when it should cool (or vice versa)

-

Show error codes that don’t point to real failures

Get pairing right at startup, and you eliminate an entire category of future headaches.

📦 Step 1: Identify What Type of Control You’re Using

Before pairing anything, you need to know how the PTAC is designed to be controlled.

Most Amana PTAC units support one or more of the following:

-

On-board control panel

-

Handheld remote

-

Wall-mounted thermostat

-

Central or occupancy-based controls (model-dependent)

Never assume the control method—verify it in the documentation before proceeding.

📘 Step 2: Review Control Compatibility Before Power-Up

Not all thermostats work with PTAC systems.

🎯 PTAC thermostat requirements

-

Designed for PTAC or packaged terminal units

-

Compatible with electric heat staging

-

Correct voltage and terminal layout

Using a standard residential thermostat on a PTAC is a common mistake—and a guaranteed source of erratic behavior.

Manufacturer guidance:

Amana PTAC Technical Resources

🔌 Step 3: Wiring Verification (Before Pairing)

If you’re using a wall thermostat, pairing starts with wiring.

🧵 Wiring best practices

-

Follow the Amana wiring diagram exactly

-

Use correct terminal labels (no guessing)

-

Ensure tight, secure connections

-

No exposed copper at terminals

Loose or crossed wires can mimic control board failures—especially during startup.

🔑 Step 4: First Power-Up with Controls in Neutral State

When powering up for the first time:

-

Set thermostat to OFF or neutral

-

Do not immediately demand heating or cooling

-

Allow the PTAC control board to initialize fully

This gives the unit a clean boot without conflicting commands during initialization.

📡 Step 5: Pairing the Remote (If Equipped)

If your Amana PTAC includes a remote, pairing is usually automatic—but verification is critical.

📲 Remote pairing checklist

-

Fresh batteries installed

-

Remote pointed directly at the unit

-

No obstructions between remote and receiver

-

Unit powered and idle (not mid-cycle)

✅ Confirm successful pairing

-

Mode changes register immediately

-

Temperature adjustments are acknowledged

-

Fan speed changes respond correctly

If the unit doesn’t respond, recheck batteries and line-of-sight before assuming a problem.

🎚️ Step 6: Thermostat Pairing & Configuration

For wall thermostats, pairing is more about configuration than syncing.

⚙️ Key thermostat settings to confirm

-

System type set to PTAC

-

Heat type set correctly (electric vs. heat pump)

-

Fan operation configured properly

-

Temperature scale correct (°F vs. °C)

Many startup issues happen because thermostats ship with default settings meant for residential furnaces—not PTACs.

🔁 Step 7: Mode-by-Mode Response Testing

Once paired, test each mode individually.

🧪 Test sequence

-

Fan-only mode

-

Cooling mode

-

Heating mode

-

Fan speed changes

-

Temperature adjustments

After each command, confirm:

-

The PTAC responds correctly

-

There’s no excessive delay

-

The unit doesn’t enter an unexpected mode

Startup is the time to catch mismatches—not after guests or occupants complain.

🕒 Step 8: Observe Control Behavior Over 15 Minutes

Let the unit run under control for at least 15 minutes.

👀 Watch for:

-

Stable temperature changes

-

No rapid cycling

-

No random mode switching

-

No error codes

If the unit behaves inconsistently, stop and recheck control wiring and configuration.

⚠️ Common Pairing Problems (and Fast Fixes)

🚨 Problem: Unit ignores thermostat commands

Likely cause: Incorrect wiring or incompatible thermostat

Fix: Verify terminal connections and model compatibility

🚨 Problem: Unit heats when set to cool

Likely cause: Reversed control wiring

Fix: Correct terminal placement

🚨 Problem: Fan runs constantly

Likely cause: Fan setting configured incorrectly

Fix: Adjust thermostat fan logic

🚨 Problem: Delayed or inconsistent response

Likely cause: Startup initialization interrupted

Fix: Perform clean power reset and re-pair

🔄 Step 9: How to Reset Controls the Right Way

If pairing goes sideways, reset properly.

🔁 Correct reset process

-

Turn unit off

-

Disconnect power completely

-

Wait 3–5 minutes

-

Restore power

-

Re-test pairing and response

Avoid rapid power cycling—it confuses control boards and creates false error states.

🚫 What Not to Do During Control Pairing

These mistakes cause most startup control problems.

❌ Avoid:

-

Pairing controls while the unit is mid-cycle

-

Using non-PTAC thermostats

-

Skipping configuration menus

-

Assuming defaults are correct

-

Ignoring delayed or partial responses

Control setup is precision work—not guesswork.

🧠 Mark’s Rule for Control Pairing

If the PTAC:

-

Responds immediately

-

Changes modes cleanly

-

Holds temperature steadily

Your control pairing is correct.

If not, don’t move forward with startup until it is.

Controls don’t “sort themselves out later.” Problems compound over time.

🧠 Mark’s Final Take

Remote and thermostat pairing at startup isn’t just a setup task—it’s a foundation.

When controls are paired correctly:

-

Startup is smooth

-

Error codes disappear

-

Comfort complaints drop

-

Equipment life improves

Take the extra time during startup to verify control behavior. It’s one of the simplest ways to prevent the most frustrating PTAC problems.