If startup is the moment a PTAC comes to life, the first 24 hours are when it proves whether it’s truly set up right.

Most PTAC issues don’t show up instantly. They reveal themselves slowly—through drifting temperatures, uneven airflow, rising humidity, or noises that weren’t there at first power-up. That’s why I always tell people: don’t declare victory after the unit turns on. Watch it for a full day.

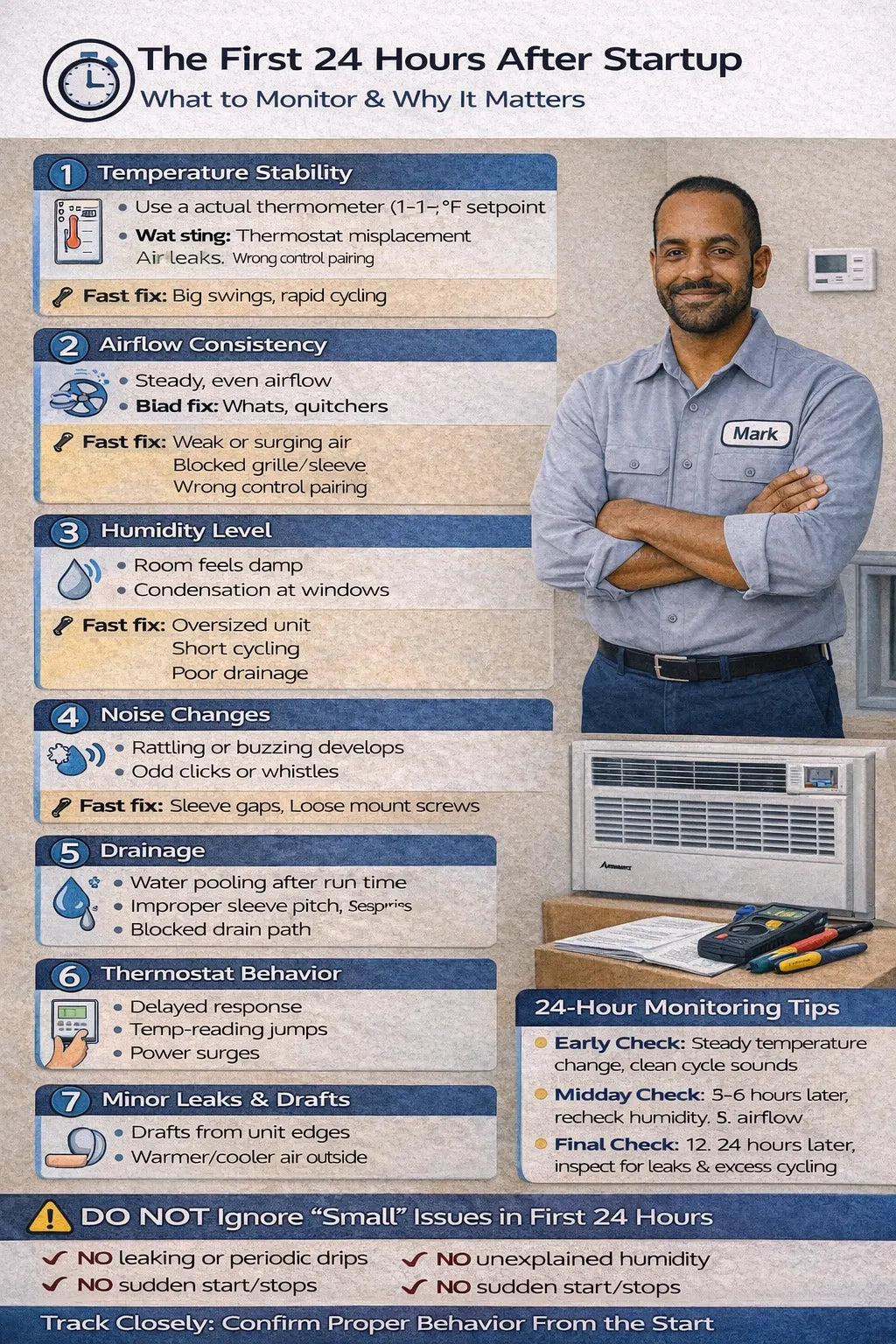

This guide walks through exactly what to monitor in the first 24 hours after initial startup, using the Amana J-Series 15,000 BTU PTAC with 3.5 kW electric heat as our reference. These checks help you catch small problems early—before they become service calls, complaints, or warranty issues.

🧠 Why the First 24 Hours Are Critical

During the first day of operation, the PTAC:

-

Cycles under real load conditions

-

Responds to room heat gain and loss

-

Manages moisture for the first time

-

Expands and contracts as components warm up

-

Reveals mounting, sealing, and control issues

A system that looks fine at startup can still fail these real-world tests. That’s why this window matters.

🌡️ Track #1: Temperature Stability

Temperature stability is the single best indicator of whether the PTAC is operating correctly.

✅ What “stable” looks like

-

Room temperature reaches setpoint gradually

-

Unit maintains temperature within 1–2°F

-

No constant overshooting or undershooting

-

Cycles feel predictable, not erratic

Use a separate thermometer if possible—don’t rely only on the thermostat display.

🚩 Warning signs

-

Temperature swings of 3–5°F or more

-

Unit running constantly without reaching setpoint

-

Rapid on/off cycling near setpoint

🛠️ Common causes

-

Thermostat misplacement or misconfiguration

-

Air leaks around the unit

-

Restricted airflow

-

Incorrect control pairing

Temperature instability is rarely a “bad unit” problem—it’s almost always setup-related.

🌬️ Track #2: Airflow Consistency & Direction

Airflow issues often appear after several hours, once the system has fully warmed up and cycled multiple times.

✅ Healthy airflow indicators

-

Steady airflow during operation

-

Even distribution across the grille

-

No sudden drops in air volume

-

No rattling or whistling sounds

🚩 Red flags

-

Weak airflow after initial strong output

-

Airflow that surges or fades

-

Noticeable drafts around the unit edges

🛠️ Common causes

-

Blocked interior grille

-

Furniture placed too close

-

Improper sleeve sealing

-

Filter not seated correctly

Airflow problems directly impact temperature control, humidity removal, and noise levels.

💧 Track #3: Humidity Control

Humidity is often ignored—until it becomes a problem.

✅ What good humidity control looks like

-

Room feels dry and comfortable

-

No clammy or sticky sensation

-

Windows and walls stay dry

-

Unit cycles normally in cooling mode

🚩 Warning signs

-

Room feels damp despite cooling

-

Condensation on windows or nearby walls

-

Musty odors developing

-

Unit running constantly but comfort still lacking

🛠️ Common causes

-

Short cycling preventing moisture removal

-

Oversized unit for the space

-

Air leaks allowing humid air infiltration

-

Drainage or airflow issues

For moisture fundamentals, see:

Energy.gov – Indoor Humidity & HVAC Basics

Humidity problems almost always trace back to cycling or airflow—not refrigerant issues.

🔊 Track #4: Noise Changes Over Time

Noise that shows up after hours—not minutes—is a big clue.

✅ Normal sounds

-

Steady fan noise

-

Soft compressor hum

-

Consistent sound profile from cycle to cycle

🚩 Warning sounds

-

Rattling that increases over time

-

Buzzing or vibrating during startup

-

Clicking when cycling

-

Whistling or air leaks around the unit

🛠️ Common causes

-

Loose mounting hardware

-

Unit not fully seated in sleeve

-

Seal gaps causing air turbulence

-

Fan imbalance exposed under longer run times

Noise complaints are one of the most common PTAC callbacks—and most are preventable in the first 24 hours.

🚿 Track #5: Condensate & Drainage Behavior

Cooling mode equals moisture. The first 24 hours tell you if the system is managing it correctly.

✅ Proper drainage signs

-

No water indoors

-

No dripping from interior grille

-

Drainage occurs outdoors

-

No gurgling or sloshing sounds

🚩 Warning signs

-

Water near the base of the unit

-

Drips from the front panel

-

Intermittent leaks after long run times

🛠️ Common causes

-

Sleeve pitched incorrectly

-

Drain openings blocked

-

Over-sealing around drain areas

Drainage problems rarely show up immediately—watch closely over time.

🎛️ Track #6: Control & Thermostat Behavior

Controls that misbehave over time were usually misconfigured at startup.

✅ Healthy control behavior

-

Commands register immediately

-

Modes change cleanly

-

Fan settings behave as expected

-

No unexplained resets

🚩 Warning signs

-

Delayed response to changes

-

Random mode switching

-

Display resets or flashing

-

Inconsistent temperature readings

These are often caused by wiring issues, incompatible thermostats, or unstable power.

Manufacturer reference:

Amana PTAC Technical Resources

🕒 Suggested 24-Hour Monitoring Timeline

You don’t need to watch the unit constantly—just check in strategically.

⏱️ First hour

-

Confirm temperature movement

-

Listen for abnormal noises

-

Verify airflow and controls

⏱️ After 4–6 hours

-

Check temperature stability

-

Feel for humidity changes

-

Inspect around the unit for moisture

⏱️ After 12–24 hours

-

Confirm consistent cycling

-

Recheck noise levels

-

Ensure no leaks or drafts have developed

This light monitoring catches 90% of early issues.

⚠️ What to Do If Something Feels “Off”

Trust your instincts.

If something seems wrong:

-

Don’t ignore it

-

Don’t force operation

-

Recheck installation basics

-

Correct the issue early

Small corrections in the first 24 hours prevent major problems later.

🚫 Common Mistakes During the First 24 Hours

Avoid these habits—they create long-term issues.

❌ Don’t:

-

Block airflow with furniture or curtains

-

Ignore new noises

-

Assume humidity issues will “settle out”

-

Walk away without checking drainage

-

Dismiss control glitches as “normal”

The system is telling you how it feels—listen.

🧠 Mark’s Rule for the First 24 Hours

If after 24 hours the PTAC:

-

Holds temperature steadily

-

Moves air consistently

-

Manages humidity

-

Runs quietly

-

Responds cleanly to controls

You’re set up for long-term success.

If not, fix it now—before the system gets blamed for problems it didn’t create.

🧠 Mark’s Final Take

The first 24 hours after startup are your best diagnostic window.

Nothing is hidden yet. Nothing is worn out. The system is fresh, honest, and responsive. If you watch temperature, airflow, humidity, and noise during this time, you’ll catch nearly every setup issue while it’s still easy to fix.

Don’t rush past this phase.

It’s the difference between a smooth-running PTAC—and months of frustration.