When a PTAC throws an error code or behaves strangely during startup, most people jump straight to one conclusion:

“The unit is defective.”

In reality, most early PTAC error signs are startup-related issues, not bad equipment. They’re the system’s way of saying something in the install, setup, or power-up sequence isn’t quite right.

In this guide, I’ll walk you through how to read those early warning signs, understand what’s really causing them, and fix the issue before it turns into downtime, damage, or a warranty headache—using the Amana J-Series 15,000 BTU PTAC as our reference point.

Amana J-Series PTAC Model 15,000 BTU PTAC Unit with 3.5 kW Electric Hea

🧠 Why Early Error Signs Happen During Startup

PTAC systems are built with safeguards. During startup, the unit checks:

-

Electrical stability

-

Airflow

-

Temperature feedback

-

Component timing

-

Safety limits

If anything falls outside acceptable ranges, the unit reacts—sometimes with an error code, sometimes with odd behavior instead.

The key thing to understand:

👉 Startup errors are usually preventable and reversible.

🔍 The Difference Between “Startup Faults” and Real Failures

Before troubleshooting, you need to know what you’re dealing with.

⚠️ Startup-related faults usually:

-

Appear during first power-up or first few hours

-

Clear after correction and reset

-

Do not return once setup is fixed

❌ True equipment failures:

-

Persist after correction

-

Reappear repeatedly

-

Show physical damage or burned components

Most of what you’ll encounter early falls into the first category.

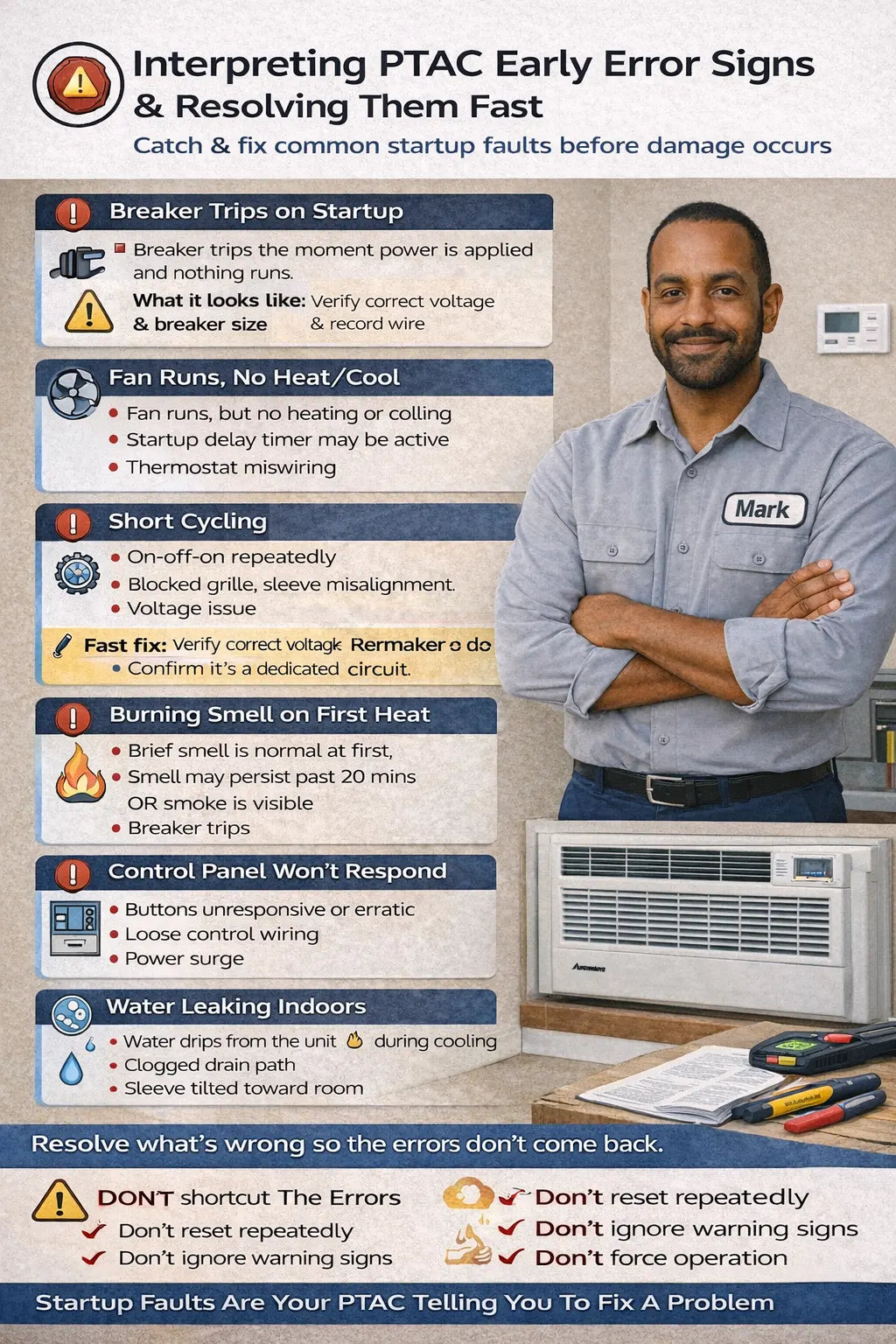

⚡ Error Sign #1: Breaker Trips Immediately on Startup

🔴 What it looks like

-

Breaker trips the moment power is applied

-

Unit never fully initializes

-

No fan or display activity

🧠 Most common causes

-

Incorrect breaker size

-

Voltage mismatch (208V vs. 230V)

-

Shared circuit with other loads

-

Loose or undersized wiring

🛠️ Fast fix

-

Do not reset repeatedly

-

Verify voltage with a tester

-

Confirm breaker size matches spec

-

Check for dedicated circuit

Manufacturer electrical guidance:

Amana PTAC Technical Resources

Repeated breaker resets cause far more damage than the original fault.

🌬️ Error Sign #2: Fan Runs, But No Heating or Cooling

🟡 What it looks like

-

Fan operates normally

-

Compressor or heater never engages

-

No temperature change

🧠 Most common causes

-

Startup delay timer still active

-

Thermostat miswiring

-

Incorrect control configuration

-

Safety lockout due to airflow issue

🛠️ Fast fix

-

Wait 5–10 minutes before assuming failure

-

Verify thermostat wiring and compatibility

-

Check airflow is unobstructed

-

Confirm correct operating mode selected

Patience solves more startup “failures” than parts replacement.

❄️ Error Sign #3: Short Cycling (On-Off-On Repeatedly)

🔴 What it looks like

-

Unit starts, stops, then restarts repeatedly

-

Compressor clicks on and off

-

Temperature never stabilizes

🧠 Most common causes

-

Restricted airflow (blocked grille, furniture)

-

Improper wall sleeve seal

-

Control sensor exposed to drafts

-

Voltage instability

🛠️ Fast fix

-

Clear airflow paths immediately

-

Verify proper sealing around unit

-

Check sleeve alignment

-

Confirm stable voltage

Short cycling is a protection response—not a malfunction.

🔥 Error Sign #4: Burning Smell During First Heat Cycle

🟡 What it looks like

-

Slight odor when electric heat engages

-

No smoke

-

Odor fades within minutes

🧠 Normal or not?

✔️ Often normal during first heat cycle

Manufacturing residues burn off during initial use.

🚫 When it’s NOT normal

-

Smell persists beyond 15–20 minutes

-

Smoke is visible

-

Breaker trips when heat engages

🛠️ Fast fix

-

Shut down immediately if odor persists

-

Inspect wiring and breaker size

-

Confirm heater capacity matches electrical supply

If in doubt, stop and investigate.

🎛️ Error Sign #5: Control Panel Unresponsive or Acting Erratically

🔴 What it looks like

-

Buttons don’t respond

-

Display flashes or resets

-

Mode changes randomly

🧠 Most common causes

-

Voltage fluctuations

-

Loose control wiring

-

Incompatible thermostat

-

Power interruptions during startup

🛠️ Fast fix

-

Power down completely

-

Inspect control wiring

-

Verify thermostat compatibility

-

Restore power cleanly

Startup interruptions confuse control boards more than steady faults.

💧 Error Sign #6: Water Dripping Indoors After Startup

🔴 What it looks like

-

Water appears under or near the unit

-

Happens during cooling mode

-

May start hours after startup

🧠 Most common causes

-

Sleeve pitched inward

-

Drain path blocked

-

Over-sealing around drain openings

🛠️ Fast fix

-

Shut down cooling mode

-

Verify outward sleeve pitch

-

Clear drain openings

-

Remove sealant blocking drains

Drainage issues are installation errors—not PTAC defects.

For moisture guidance, see:

Energy.gov – HVAC Moisture Control

⚠️ Error Sign #7: Error Code Appears, Clears, Then Returns

🟡 What it looks like

-

Error code shows up during startup

-

Clears after reset

-

Reappears under load

🧠 What this usually means

-

Intermittent electrical issue

-

Borderline airflow condition

-

Sensor reading out of range

🛠️ Fast fix

-

Identify when the code appears (cooling, heating, fan-only)

-

Check conditions during that mode

-

Correct root cause—not just reset

Repeated resets without correction make things worse.

🔁 How to Reset Properly (Without Making Things Worse)

Resetting a PTAC isn’t about flipping power repeatedly.

✅ Correct reset process

-

Turn unit off

-

Disconnect power completely

-

Wait 3–5 minutes

-

Restore power

-

Observe full startup sequence

This allows capacitors to discharge and controls to reboot cleanly.

🚫 What Not to Do When Errors Appear

These mistakes turn small issues into big ones.

❌ Avoid:

-

Repeated breaker resets

-

Ignoring smells or sounds

-

Forcing operation through errors

-

Assuming error codes = bad unit

-

Skipping airflow and sealing checks

Most PTACs are trying to protect themselves—not fail.

🧠 Mark’s Startup Error Rule of Thumb

If an error:

-

Appears early

-

Disappears after correction

-

Never returns

It was a startup fault, not a defect.

If an error:

-

Persists

-

Escalates

-

Causes repeated shutdowns

Stop and diagnose before damage occurs.

🧠 Mark’s Final Take

PTAC error signs during startup are messages, not verdicts.

They’re the unit telling you:

-

Something is off

-

Something needs attention

-

Something can be fixed right now

If you slow down, observe carefully, and fix the root cause instead of chasing symptoms, most startup errors disappear for good.

The fastest way to resolve PTAC errors isn’t rushing—it’s understanding what the system is trying to tell you.