If there’s one thing homeowners complain about more than uneven temperatures, it’s noise.

“That PTAC is too loud.”

“The hum keeps me up.”

“The vibration shakes the wall.”

“It clicks, thumps, buzzes… something’s wrong.”

Most of the time? Nothing is “wrong” with the PTAC itself.

The noise comes from poor system design — the placement, the wall structure, the airflow angles, the electrical routing, and the sleeve.

A PTAC that’s installed with noise-smart design can be whisper quiet.

A PTAC installed without noise planning? It’ll make your room sound like a motel from 1983.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

So I built a field-tested process called Mike’s Noise-Smart System Design Rules — techniques that reduce or eliminate:

-

Hum

-

Vibration

-

Rattle

-

Sleeve resonance

-

Air turbulence

-

Compressor noise

-

Wall echo

-

Furniture reverberation

Below is everything you need to design a PTAC layout that runs smooth and quiet for its entire lifespan.

🔊 1. Where PTAC Noise Actually Comes From (It’s Not the Unit Itself)

Here’s the truth: Most PTAC noise is not created inside the PTAC.

Noise is created by:

-

The wall structure

-

The sleeve mounting

-

The airflow

-

The room geometry

-

The furniture

-

The power lines

-

The materials used during installation

The unit is just the amplifier. The room is the speaker box.

🧱 2. Structural Resonance — The #1 Noise Source Most People Ignore

When the PTAC runs, it generates:

-

Vibration

-

Low-frequency hum

-

Motor resonance

-

Air turbulence

-

Compressor kick

If the wall system is weak, hollow, or poorly framed, the whole wall becomes a noise amplifier.

This is why many PTACs seem louder at night — resonance increases when background noise decreases.

Mike’s Rule:

Noise begins in the wall, not in the unit.

Signs of structural resonance:

-

The wall vibrates when the fan kicks on

-

Noise gets louder during high heat-strip use

-

You hear a “drum” or “echo” when tapped

-

The noise spreads across the entire room

-

Rattles appear even when PTAC is properly maintained

Fixes:

-

Reinforce framing (header + jack studs)

-

Add rigid plywood sheathing behind the sleeve

-

Use rubber isolation pads

-

Seal gaps with acoustic caulk

-

Add mineral wool inside the cavity if possible

Reference (ASHRAE Sound & Vibration Control)

🎯 3. The “No-Echo Wall Test” (Mike’s Quick Diagnostic)

Before choosing a wall, do this:

-

Knock on the wall.

-

Listen carefully:

-

Hollow, loud, ringing sound → terrible for PTAC noise

-

Thick, dense, muted sound → perfect for PTAC noise control

-

If hollow, reinforce the wall before the installation.

Noise-smart system design starts here.

🧰 4. Sleeve Vibration — The Silent Noise Multiplier

The PTAC sleeve is a metal box.

Metal vibrates.

Metal amplifies sound.

If the sleeve isn’t:

-

Reinforced

-

Pitched properly

-

Caulked correctly

-

Stabilized with isolation pads

-

Installed into a solid wall frame

…it’ll become a noise machine.

Mike’s Sleeve Noise Rules:

✔️ Sleeve MUST be fastened to studs — never drywall.

✔️ Use rubber isolation pads under all contact points.

✔️ Apply acoustic caulk where sleeve meets framing.

✔️ Never overtighten screws — it warps the sleeve.

✔️ Use a rigid backer (plywood or OSB) behind thin drywall.

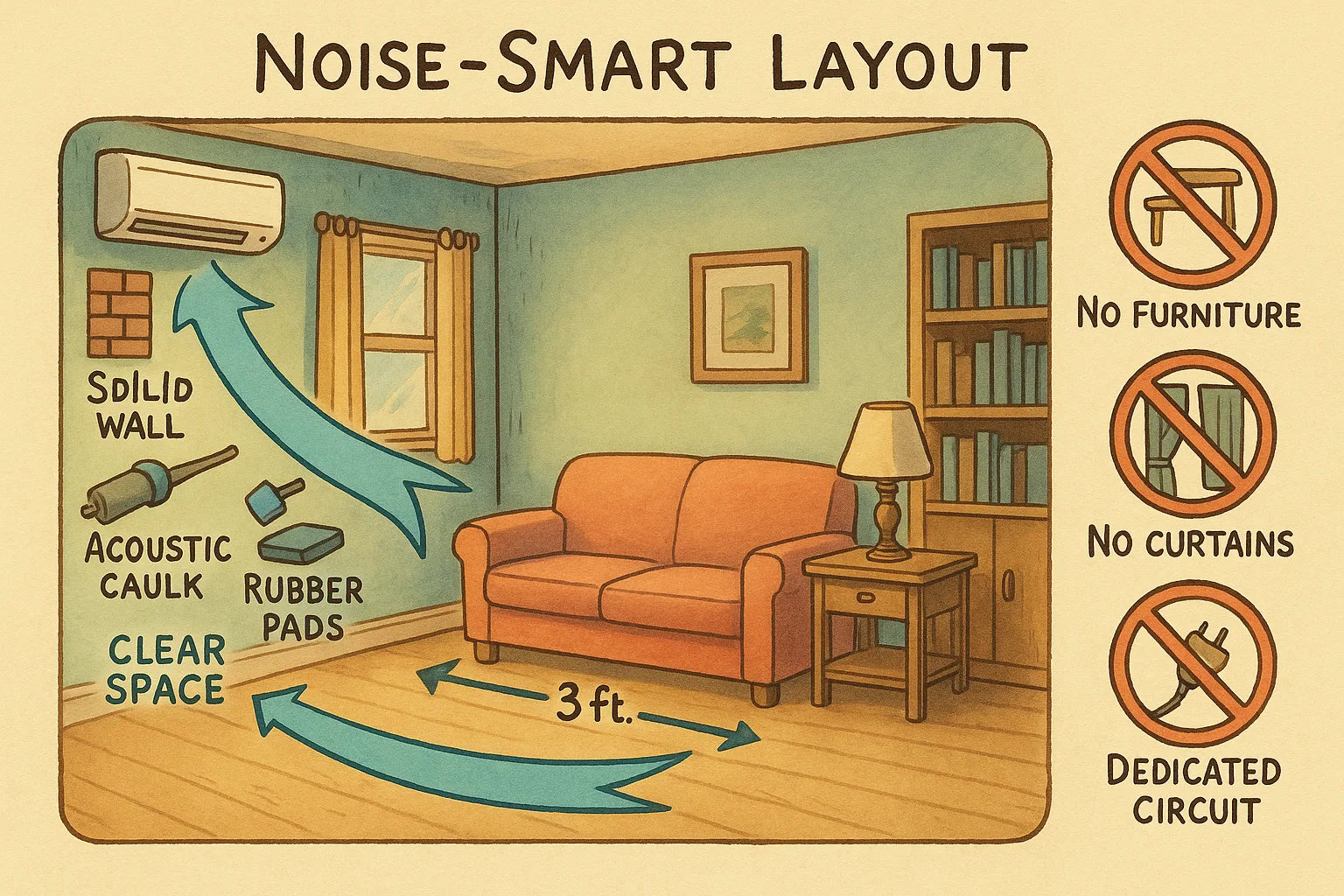

🌬️ 5. Airflow Noise — The Hidden Culprit

Many homeowners mistake air turbulence for “loud PTAC noise.”

Air turbulence happens when:

-

Louvers aim too hard at a wall

-

Curtains block airflow

-

Furniture obstructs circulation

-

Air hits the ceiling too soon

-

Air curls around obstacles

-

The PTAC is installed too low

-

CFM is too high for room geometry

Fix Airflow, Fix Noise.

Mike’s airflow quieting rules:

✔️ Aim louvers upward 10–15° for longer throw.

✔️ Avoid blasting air at walls or bed frames.

✔️ Keep 3 feet of open space in front of the unit.

✔️ Don’t let curtains billow over the PTAC.

✔️ Never install a PTAC under a deep window sill.

✔️ Let airflow follow the longest wall in the room.

DOE airflow guideline resource:

https://www.energy.gov/energysaver/room-air-conditioners

🔌 6. Electrical Noise — Buzz, Hum & Surge Problems

Electrical noise often comes from:

-

Shared circuits

-

Undersized wiring

-

Loose grounding

-

Voltage drop

-

Heat kit overload

-

Old or poorly wired outlets

PTAC heaters (especially 3.5 kW and up) require 230/208V dedicated circuits.

Mike’s Quiet Power Rules:

✔️ Always use a dedicated circuit.

✔️ Use correct wire gauge:

-

12/2 for 20A

-

10/2 for 30A

✔️ Avoid shared circuits with:

-

TVs

-

Lighting

-

Microwaves

-

Space heaters

-

Computers

✔️ Test circuit load before installation.

✔️ Hardwire high-load PTACs when possible.

You remove 50–70% of electrical hum simply by isolating the circuit.

📐 7. The Perfect PTAC Height for Quiet Operation

Height shapes airflow.

Airflow shapes noise.

✔️ Too low → air hits floor → turbulence → noise

✔️ Too high → air hits ceiling → flutter noise

Mike’s noise-smart height rule:

Install PTAC 8–12 inches below window sill

OR

18–24 inches above the floor (if no sill).

This gives:

-

Smooth airflow arc

-

No floor turbulence

-

No ceiling ricochet

-

Quiet operation

Most noisy PTACs are installed too low.

🛋️ 8. Room Layout — Furniture Can Double the Noise Level

Bad layout can turn a quiet PTAC into a loud one.

Furniture pieces that amplify noise:

-

Beds

-

Dressers

-

Tall bookshelves

-

TV stands

-

Recliners

-

Sofas

-

Corner tables

Mike’s layout rules:

✔️ Keep heavy furniture AT LEAST 3 ft away from the unit.

✔️ Don’t place tall furniture opposite the PTAC — it reflects sound.

✔️ Leave a clear airflow path into the room.

✔️ Keep fabrics (curtains, blankets) far from the unit.

✔️ Avoid corner installs unless airflow allows it.

🧊 9. Compressor Noise — When It's the Unit, Not the Room

Sometimes the PTAC itself is loud — but only in certain modes.

Compressor noise is normal at startup, but:

✔️ Long, loud rumbling

✔️ Metallic grinding

✔️ High-frequency whine

✔️ Rattle that increases over time

…indicate issues with:

-

Fan motor alignment

-

Refrigerant flow

-

Bearing wear

-

Obstruction in blower wheel

-

Loose compressor mount

Fix:

Routine inspection per ENERGY STAR maintenance guidelines

🧯 10. Vibration Control — Mike’s “Three-Layer Quiet Fix”

This is my most reliable method for making any PTAC whisper-quiet:

Layer 1 — Structural Isolation

Rubber pads + acoustic caulk between sleeve and framing.

Layer 2 — Sleeve Stabilization

Foam gasket kits + anti-vibration tape on all metal interfaces.

Layer 3 — Unit Isolation

Rubber washers on mounting screws + vibration dampeners under compressor mounts.

This eliminates:

-

Buzz

-

Hum

-

Metal rattle

-

Low-frequency resonance

Do all three and the PTAC becomes nearly silent.

🧭 11. Wall Placement — Some Walls Will NEVER Be Quiet

There are walls I simply refuse to install into.

Never install in walls with:

-

Hollow metal studs

-

Shared plumbing lines

-

Thin drywall with no backing

-

Masonry with interior echo

-

Floating floors behind the wall

-

Loose siding or paneling

-

High traffic vibration zones (stairs, doors, garages)

-

Shared bedroom walls

Wrong wall → guaranteed noise issues.

📊 12. Mike’s Noise-Smart Pre-Install Checklist

Wall & Structure

-

☐ Wall passes the “No-Echo Test”

-

☐ Reinforced framing in place

-

☐ Sleeve mounted to studs only

-

☐ Acoustic caulk applied

Airflow & Layout

-

☐ 3 ft clear in front

-

☐ Louvers angled upward

-

☐ No reflective furniture facing unit

-

☐ No curtains in airflow path

-

☐ Air aimed toward longest path

Power

-

☐ Dedicated circuit

-

☐ Correct wire gauge

-

☐ Clean ground

-

☐ No shared loads

-

☐ Hardwire if possible

Drainage & Pitch

-

☐ Sleeve pitched outward

-

☐ No turbulence from improper drainage

Isolation

-

☐ Rubber gaskets installed

-

☐ Vibration pads installed

-

☐ Anti-resonance tape applied

If every box is checked — the PTAC will operate whisper-quiet.

🎯 Conclusion: Quiet PTACs Aren’t Lucky — They’re Designed

Noise is not a PTAC flaw.

Noise is a system design flaw.

Quiet operation comes from:

✔️ Smart wall choice

✔️ Proper sleeve installation

✔️ Structural isolation

✔️ Clear airflow geometry

✔️ Correct louver angle

✔️ Clean electrical design

✔️ Furniture placement

✔️ Vibration layering

Follow these noise-smart layout rules and your PTAC will run quiet, smooth, and efficient for years.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: Energy Zones & Smart Placement: Mike’s Guide to Designing Homes for Lower Operating Costs