If you’ve invested in a Daikin 12.5 Ton 14.4 IEER2 Packaged Air Conditioner, you already know it’s a powerhouse for keeping commercial spaces comfortable. But just like a truck hauling heavy loads every day, this system demands regular care to stay efficient, reliable, and long-lasting.

I’ve installed and managed several of these big commercial units across offices, retail spaces, and one very stubborn restaurant project. Through trial, error, and a lot of summer service calls, I’ve built a maintenance routine that keeps these systems running like new.

This guide walks through everything you need to know—from DIY filter swaps to professional service intervals—so you can maximize your Daikin’s performance and avoid costly breakdowns.

⚙️ Why Maintenance Is Critical for Large Packaged Units

Skipping maintenance on a 12.5-ton packaged unit isn’t just risky—it’s expensive.

-

Energy Efficiency Loss: Dirty coils or clogged filters can raise energy use by 10–30% (U.S. DOE).

-

Shortened Lifespan: Neglected systems often fail 5–7 years earlier than expected.

-

Comfort Issues: Poor airflow leads to hot/cold spots and humidity problems.

-

Downtime Costs: For a business, a failed unit means lost customers or productivity.

👉 My rule of thumb: spend a few hundred dollars each year on maintenance, and you’ll save thousands in repairs and energy bills.

🧹 Step 1: Air Filter Management

Why It Matters

Air filters are your first line of defense. They trap dust, pollen, and debris before it clogs your coils. A clogged filter means:

-

Restricted airflow

-

Frozen coils

-

Overworked blower motors

Mark’s Routine

-

Check monthly during peak summer.

-

Replace every 1–3 months depending on occupancy and dust.

-

Buy filters by the case—cheaper and ensures I never “forget.”

👉 One time I skipped filter changes for three months in a high-traffic retail space. The result? A 15% higher electric bill and a blower motor that nearly gave up. Lesson learned.

📖 ENERGY STAR offers a filter replacement guide with intervals by environment.

🌀 Step 2: Coil Cleaning

Why It Matters

The condenser and evaporator coils are where heat transfer happens. Dirt buildup:

-

Blocks airflow

-

Lowers efficiency

-

Raises compressor pressure

Mark’s Routine

-

Inspect twice per year—spring and fall.

-

Clear leaves and debris from rooftop coils.

-

Spray fins with a garden hose (low pressure).

-

Use coil cleaner once a year for deeper cleaning.

👉 I once saw a restaurant unit’s condenser completely caked with grease from the kitchen exhaust. After cleaning, the energy bill dropped 20%.

📖 The HVAC School Guide to Coil Cleaning explains proper cleaning techniques without damaging fins.

🔍 Step 3: Duct & Airflow Checks

Why It Matters

Leaky ducts = wasted cooling. The DOE estimates 20–30% of air leaks out of commercial duct systems (ENERGY STAR).

Mark’s Routine

-

Inspect ducts annually for gaps, rust, or crushed sections.

-

Seal with mastic + foil tape (never cloth duct tape).

-

Balance dampers to ensure even cooling across rooms.

👉 On one office building, I found a collapsed return duct reducing airflow by 40%. The tenants thought the AC was broken—it was just a $50 duct repair.

⚡ Step 4: Electrical & Controls

Why It Matters

Loose electrical connections = high resistance = heat buildup = fire risk.

Mark’s Routine

-

Annual check by a licensed electrician or HVAC pro.

-

Tighten lugs and check for discoloration.

-

Test thermostat for accuracy.

-

Inspect safety switches.

👉 My tip: label thermostat wires during inspections. I once reversed fan/compressor wires and spent two hours re-tracing them.

📖 NFPA provides electrical safety codes for commercial HVAC installations.

🛢️ Step 5: Belts, Bearings & Moving Parts

Why It Matters

Blower motors and fans are the hardest-working parts of your Daikin unit. Worn belts or unlubricated bearings cause vibration, noise, and breakdowns.

Mark’s Routine

-

Inspect belts twice per year for cracks or fraying.

-

Keep spare belts on site for emergencies.

-

Lubricate bearings as recommended in Daikin’s manual.

👉 One summer, a belt snapped during lunch rush at a diner I manage. With a spare on hand, I swapped it in 15 minutes instead of waiting hours for a supplier.

📖 Daikin provides service manuals with lubrication and belt replacement intervals.

❄️ Step 6: Refrigerant & Performance Monitoring

Why It Matters

Low refrigerant = poor cooling and a stressed compressor. Too much refrigerant = high pressure and system damage.

Mark’s Routine

-

Annual refrigerant check with gauges by a licensed tech.

-

Confirm a 20°F temperature difference between supply and return air.

-

Keep service logs to track performance year over year.

👉 I once caught a slow refrigerant leak during routine checks. Fixing it early saved the compressor and thousands in repairs.

📖 Learn more about refrigerant checks at EPA Section 608 Technician Resources.

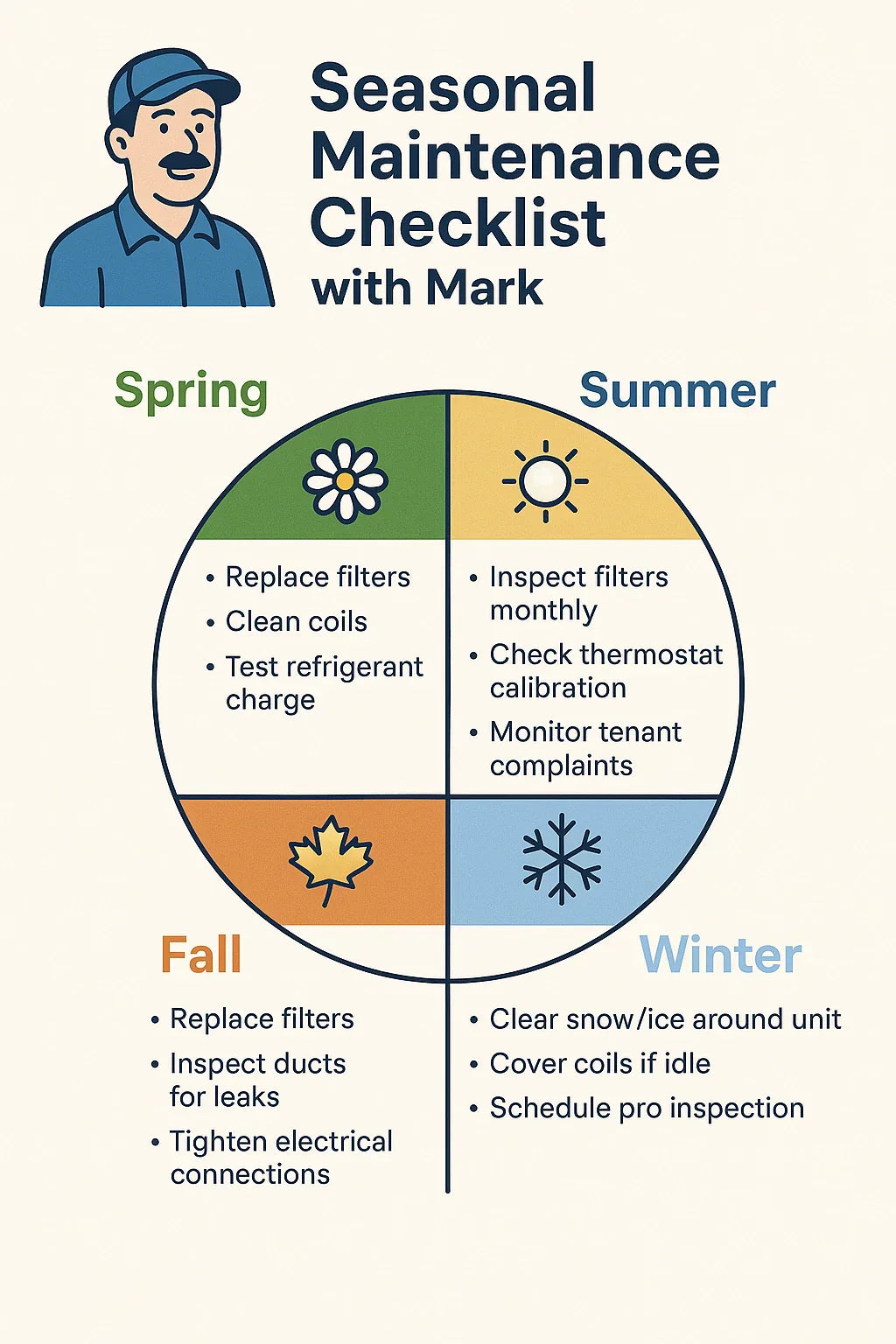

📅 Step 7: Seasonal Maintenance Checklist

Here’s the schedule I follow every year:

🌸 Spring

-

Replace filters

-

Clean coils

-

Test refrigerant charge

☀️ Summer

-

Inspect filters monthly

-

Check thermostat calibration

-

Monitor tenant complaints for airflow issues

🍂 Fall

-

Replace filters

-

Inspect ducts for leaks

-

Tighten electrical connections

❄️ Winter

-

Clear snow/ice around rooftop units

-

Cover coils if unit is idle

-

Schedule pro inspection before next cooling season

📖 The ACCA Maintenance Checklist offers a full professional guideline.

🧑🔧 DIY vs. Professional Maintenance

What I Handle Myself

-

Filters

-

Coil cleaning

-

Visual inspections

-

Belt swaps

What I Leave to Pros

-

Refrigerant handling

-

Deep electrical testing

-

Annual commissioning reports

👉 Skipping professional service can void your Daikin warranty, so balance DIY savings with warranty protection.

📖 Daikin warranty details are available at Daikin’s Commercial Warranty Page.

💵 Maintenance Cost vs. Repair Cost

-

Annual maintenance: $500–$1,000 per unit

-

Major repair (compressor replacement): $4,000–$7,000

-

Full system replacement: $25,000+

👉 Preventive care isn’t just smart—it’s financial survival for property managers.

📖 Commercial HVAC Maintenance Costs confirms these ranges.

✅ Final Thoughts

A 12.5-ton Daikin packaged unit is built for 15–20 years of service—but only if you maintain it. From simple filter changes to professional refrigerant checks, the small tasks add up to major savings in performance, efficiency, and reliability.

My advice after years of managing these systems:

-

Stay consistent with a seasonal checklist.

-

Budget yearly maintenance as part of operating costs.

-

Fix small issues early before they snowball into major repairs.

Do this, and your Daikin won’t just run—it’ll run like new for decades.

In the next topic we will know more about: Troubleshooting Guide: What to Do If Your 12.5 Ton Packaged AC Isn’t Cooling Properly