When I decided to upgrade one of my properties with a Daikin 12.5 Ton 14.4 IEER2 Light Commercial Packaged Air Conditioner, I knew it was going to be a serious project. Unlike smaller residential systems, a 12.5-ton packaged unit isn’t something you just slide into place. It’s a massive piece of equipment—about the size of a small car—requiring careful planning, skilled labor, and precise setup.

In this guide, I’ll walk you step by step through the installation process I experienced, including what went smoothly, what I’d do differently, and lessons I learned that could save you time and money.

🧰 Why Installation Matters So Much

Installing a commercial packaged unit is more than just a heavy lift—it directly impacts:

-

Energy efficiency (bad ductwork = wasted cooling)

-

System lifespan (poor wiring = early failure)

-

Comfort (improper airflow = hot/cold spots)

-

Safety (electrical or refrigerant mishandling = hazards)

📖 According to ASHRAE, installation quality accounts for up to 30% of system performance over its life.

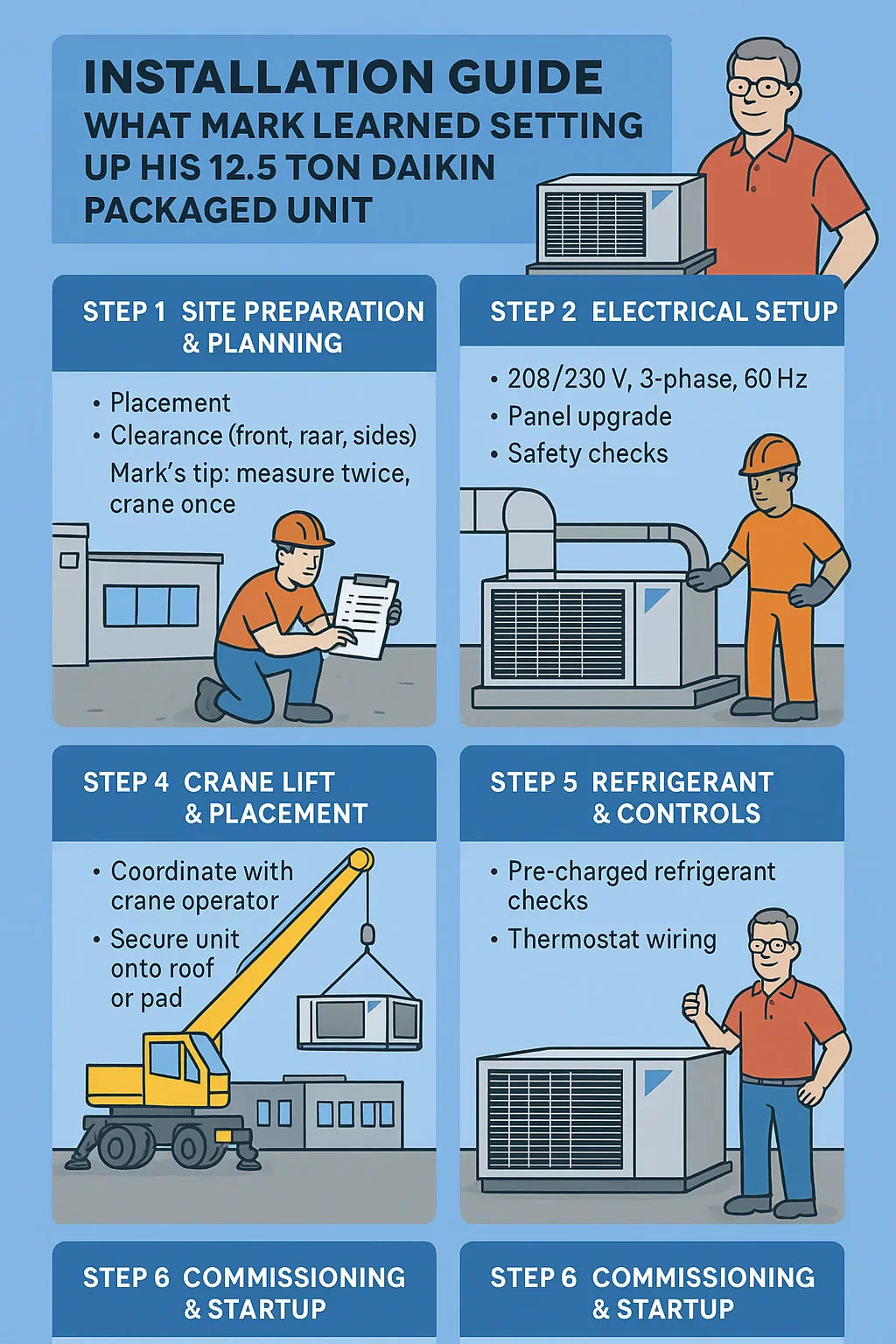

🏗️ Step 1: Site Preparation & Planning

Before the unit even arrived, I had to make some big decisions.

📍 Rooftop vs. Ground Pad

-

Rooftop saves ground space, reduces vandalism risk, and provides better airflow.

-

Ground pad makes maintenance easier but requires more clearance and fencing.

➡️ For my 9,000 sq. ft. office building, I chose rooftop placement to keep parking lot space clear.

📏 Clearance Requirements

Daikin recommends:

-

3 ft. front and back clearance for service access

-

5 ft. overhead clearance for proper airflow

-

18 in. above the roof or pad for drainage

👉 My mistake: I underestimated side clearance at first and had to reposition ducts.

📖 See Daikin Commercial Installation Guides for specific clearance charts.

⚡ Step 2: Electrical Setup

A 12.5-ton Daikin isn’t something you just plug in.

🔌 Voltage & Phase Requirements

-

208/230V, 3-phase, 60 Hz

-

Minimum circuit ampacity: ~75–100 amps

-

Disconnect switch required within line of sight

🛠️ Panel Upgrade

My existing panel didn’t have the capacity. I had to:

-

Upgrade to a 200-amp service panel

-

Run a new conduit with copper wiring (per NEC standards)

-

Add surge protection

📖 For commercial electrical codes, see NFPA 70 – National Electrical Code.

👉 Lesson learned: Budget an extra $2,000–$5,000 for electrical upgrades if your building is older.

🌬️ Step 3: Ductwork & Airflow

This step is where many installations go wrong.

📐 Airflow Requirements

The 12.5-ton Daikin pushes ~5,000–6,000 CFM. If your ductwork can’t handle that, you’ll get:

-

Noisy operation

-

Hot/cold spots

-

Strain on the blower motor

🔧 My Ductwork Adjustments

-

Increased return duct size from 18" to 22" diameter.

-

Added flex duct dampers to balance zones.

-

Resealed all joints with mastic + foil tape.

📖 ENERGY STAR notes that 20–30% of air leaks out of ducts if improperly sealed

👉 My tip: Spend extra time here—good airflow equals lower bills and happier tenants.

🏗️ Step 4: Crane Lift & Placement

This was the most dramatic part of the install.

🚧 Safety Prep

-

Blocked off parking lot.

-

Added roof protection boards to prevent damage.

-

Marked placement spot with chalk lines.

🏗️ Crane Day

-

Coordinated with a licensed crane operator ($1,200 half-day rental).

-

Rigged the Daikin unit with spreader bars to avoid denting the casing.

-

Slowly lowered onto roof curb.

👉 Lesson: Schedule crane lifts early morning to avoid wind gusts. Ours was delayed by a storm, costing an extra hour.

📖 OSHA provides crane safety guidelines for HVAC lifts (OSHA Crane Safety Guide).

🔄 Step 5: Refrigerant & Controls

Unlike older systems, modern packaged units often come pre-charged. Still, verification is key.

❄️ Refrigerant Check

-

Verified factory charge levels.

-

Checked for leaks at connections using electronic leak detector.

📡 Control Wiring

-

Connected thermostat wiring to the rooftop unit’s low-voltage board.

-

Installed programmable commercial thermostat with lockout feature (prevents tenants from setting 60°F all day).

📖 More on control strategies at DOE – Commercial HVAC Controls.

👉 Lesson: Label every wire. I had to redo mine after confusing fan vs. compressor leads.

🧪 Step 6: Commissioning & Startup

Final step: ensuring the system runs as expected.

✅ Startup Checklist

-

Power on and verify voltage balance across phases.

-

Test blower motor amperage draw.

-

Measure supply vs. return air temperature (looking for ~20°F difference).

-

Adjust thermostat programming for building hours.

📖 ASHRAE recommends commissioning reports for every new install (ASHRAE Commissioning Resources).

👉 My first test showed a 16°F delta T—slightly low. After adjusting airflow, it hit 20°F.

🧑🔧 Mark’s Key Lessons Learned

-

Budget Extra – Expect $3,000–$7,000 in electrical and crane costs beyond the unit.

-

Over-Communicate with Contractors – Make sure duct guys, electricians, and crane operator are aligned.

-

Plan for Growth – I left space on the curb for a possible future add-on unit.

-

Document Everything – Photos of wiring and duct connections saved me later during troubleshooting.

-

Don’t Skimp on Controls – A smart thermostat avoids wasted cooling during off-hours.

⚖️ DIY vs. Professional Install

-

DIY Feasible? Only if you’re licensed for electrical and have access to a crane.

-

Pro Install Recommended: Yes, especially for warranty protection.

💵 Cost Breakdown

Here’s what my install looked like (2025 pricing):

-

Unit cost (Daikin 12.5 Ton): $14,000–$18,000

-

Crane rental: $1,200

-

Electrical upgrades: $3,500

-

Duct modifications: $2,000

-

Labor (HVAC contractor): $4,000–$6,000

👉 Total: $25,000–$30,000 installed

✅ Final Thoughts

Installing a Daikin 12.5 Ton 14.4 IEER2 packaged unit is not a weekend project—it’s a complex operation requiring skilled trades, careful planning, and attention to detail.

From my experience:

-

Plan ahead for electrical capacity.

-

Don’t underestimate ductwork upgrades.

-

Schedule your crane early.

-

Always commission before signing off.

Do it right, and you’ll have 20+ years of reliable cooling with lower operating costs and happier tenants.

In the next topic we will know more about: Maintenance Tips: Keeping Your 12.5 Ton Daikin Running Like New