When a 12.5 Ton Daikin packaged AC suddenly stops cooling, panic sets in quickly. A system this size usually serves an entire office, retail space, or restaurant—and when it fails, comfort drops, productivity suffers, and customers complain.

The good news? Many cooling problems are caused by simple, fixable issues. Over the years, managing several of these large commercial units, I (Mark) learned that not every no-cooling call requires a new compressor. Sometimes it’s as easy as changing a filter or flipping a breaker.

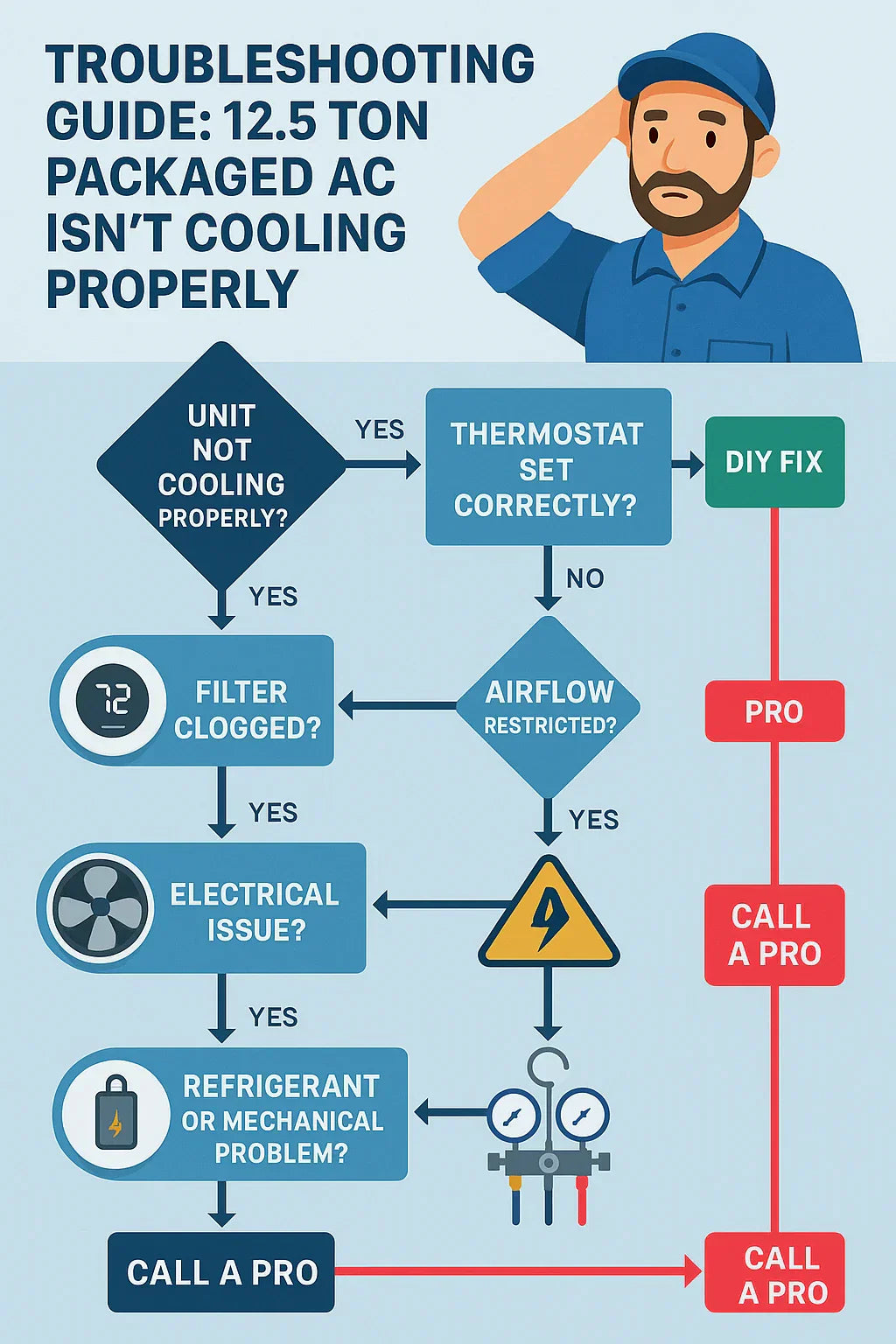

This guide walks you through a step-by-step troubleshooting process, blending DIY checks with pro-level diagnostics, so you know what to do, when to act, and when to call in an HVAC technician.

❄️ Why Your 12.5 Ton AC Might Stop Cooling

Before diving into steps, let’s outline the most common reasons:

-

Airflow restrictions (dirty filters, blocked ducts)

-

Electrical issues (blown fuses, loose wiring)

-

Refrigerant problems (leaks, low charge)

-

Mechanical failures (fans, compressors)

-

Control malfunctions (thermostats, sensors)

📖 According to ASHRAE, 70–80% of cooling complaints can be traced to improper maintenance or simple system checks.

🧹 Step 1: Check the Basics (Quick Fixes)

Start simple before assuming the worst.

-

Thermostat Settings

-

Confirm it’s set to cooling mode.

-

Lower the setpoint at least 3–5°F below room temperature.

-

Check programmable settings (off-hours may be overriding).

-

-

Power Supply

-

Inspect the breaker panel—large commercial units often have their own disconnect.

-

Reset tripped breakers once, but don’t keep flipping—recurring trips mean a deeper issue.

-

-

Air Filters

-

Pull out filters and inspect for dirt.

-

A clogged filter can freeze coils and stop airflow entirely.

-

👉 Mark’s Tip: I once got a $500 service call for a “dead unit.” The only problem? A thermostat had been left on “heat.” Always start with the obvious.

📖 See ENERGY STAR Filter Guide for simple maintenance steps.

🌀 Step 2: Airflow Issues

Airflow problems are the most common cause of poor cooling in a 12.5-ton system.

-

Blocked Supply or Return Vents

-

Check furniture, storage boxes, or rugs covering vents.

-

Verify rooftop intake screens are clear of debris.

-

-

Collapsed or Leaky Ducts

-

Look for crushed sections, holes, or disconnected duct joints.

-

Seal leaks with mastic—not duct tape.

-

-

Dirty Coils

-

Evaporator or condenser coils clogged with dirt or grease reduce heat transfer.

-

Ice on evaporator coils signals airflow or refrigerant problems.

-

👉 Mark’s Story: At one restaurant property, the return duct collapsed in the attic. Tenants thought the AC failed completely—it was just suffocating for air.

📖 DOE notes that duct leakage can waste 20–30% of cooling energy (ENERGY STAR Duct Guide).

⚡ Step 3: Electrical & Controls

Large packaged units rely on three-phase power. Small electrical issues can stop the whole system.

-

Check Disconnects

-

Each rooftop unit has a safety disconnect nearby. Verify it’s fully engaged.

-

-

Fuses and Breakers

-

Test continuity on fuses with a multimeter.

-

Replace only with manufacturer-rated fuses.

-

-

Loose Wiring

-

Vibration can loosen connections over time.

-

Look for discoloration or burnt wire insulation.

-

-

Thermostat or Control Board

-

Batteries in commercial thermostats can fail.

-

If the screen is blank, replace batteries before calling a tech.

-

👉 Mark’s Mistake: I once mislabeled thermostat wires and spent hours wondering why the compressor kept shutting down. Always label wires before pulling them.

📖 Refer to NFPA Electrical Safety Codes for compliance standards.

❄️ Step 4: Refrigerant Problems

When airflow and power are fine but cooling is weak, refrigerant is a likely culprit.

-

Signs of Low Refrigerant

-

Ice buildup on evaporator coil

-

Bubbling or hissing noises

-

Supply air not 18–22°F cooler than return

-

-

Causes

-

Slow leaks at fittings

-

Failed coil or line set

-

Improper installation charge

-

⚠️ Important: Only EPA Section 608 certified technicians can legally handle refrigerants.

👉 Mark’s Rule: Never “top off” refrigerant. Find and fix the leak, or you’ll pay for refrigerant again in six months.

📖 Learn more at EPA Section 608 Refrigerant Rules.

🛠️ Step 5: Mechanical Failures

If your unit has power and airflow but still isn’t cooling, the issue may be mechanical.

-

Compressor Failure

-

Humming but not starting = bad capacitor.

-

Silent = possible motor or control board failure.

-

-

Fan/Blower Motors

-

Outdoor fan not spinning = motor failure or capacitor issue.

-

Indoor blower not running = broken belt, relay issue.

-

-

Belts & Bearings

-

Worn belts cause squealing noises and reduced airflow.

-

Seized bearings cause loud grinding.

-

👉 Mark’s Experience: Keeping spare belts onsite has saved me hours of downtime on retail properties when a blower failed unexpectedly.

📖 Daikin’s Service Manuals provide belt specs and part numbers.

📊 Step 6: Performance Monitoring

Even if everything runs, your unit may underperform.

-

Temperature Split Test

-

Measure supply air and return air temps.

-

A healthy system shows 18–22°F difference.

-

-

Humidity Levels

-

If indoor air feels clammy, the system may be short cycling.

-

Oversized systems often cool air but don’t dehumidify.

-

-

Energy Bills

-

Sudden spikes = efficiency loss from dirty coils, leaking ducts, or refrigerant issues.

-

👉 Mark’s Tip: I log supply/return temps monthly. When I see that delta shrink to 15°F, I know it’s time for coil cleaning or a refrigerant check.

📖 Learn about commercial performance testing at ASHRAE Commissioning Resources.

🧑🔧 When to Call a Professional

Some tasks are safe for property managers, but others require licensed HVAC pros.

DIY Tasks:

-

Checking filters, ducts, vents

-

Cleaning coils

-

Resetting breakers

Pro-Only Tasks:

-

Refrigerant leak detection and charging

-

Compressor replacements

-

Electrical testing beyond breakers

-

Control board replacements

👉 My rule: If it involves refrigerant or high-voltage testing, step back and call a pro.

✅ Conclusion

A 12.5-ton packaged Daikin AC is a workhorse—but even the strongest systems hit snags. With a systematic troubleshooting process, you can quickly identify whether the issue is a simple DIY fix (filter, thermostat, breaker) or a professional-level repair (refrigerant, compressor, wiring).

From my experience:

-

Start simple before assuming the worst.

-

Keep spare belts and filters on hand.

-

Track performance over time with temperature logs.

-

Build a relationship with a trusted HVAC contractor for the heavy lifting.

Follow these steps, and you’ll cut downtime, reduce emergency calls, and keep your Daikin cooling smoothly for years to come.

In the next topic we will know more about: Clearance & Placement: Will a 12.5 Ton Packaged Unit Fit on Your Roof or Pad?