🛠️ Introduction: The Heat You Paid For… That Never Reaches You

Let me give it to you straight:

Most propane and gas unit heaters don’t underperform because they’re weak. They underperform because they’re pointed wrong.

Mount a heater 18" too high?

You just lost 20–30% of your usable heat.

Aim it straight instead of at a 15–20° downward angle?

Congratulations — your heat is trapped at the ceiling.

Pick a heater with good BTUs but terrible throw distance?

Now you’re heating the first six feet of the shop and nothing else.

This article breaks down the rules I use on every installation — especially with workhorses like the Reznor UDX 60,000 BTU Propane Unit Heater — to guarantee heat actually reaches the floor, tools, vehicles, and workbenches where people live.

🎯 1. Understanding Throw Distance — The Most Ignored Spec in HVAC

Throw distance is how far heated air can travel before it slows down to ineffective velocity.

Manufacturers rarely advertise it in big letters, and most installers ignore it.

But here’s the reality:

If your heater can’t throw warm air to the opposite wall, it can’t heat the room.

Typical throw distances:

| Heater Size | Average Throw Distance |

|---|---|

| 30,000 BTU | 12–20 feet |

| 45,000 BTU | 18–30 feet |

| 60,000 BTU | 25–40 feet |

| 80,000 BTU | 35–50 feet |

If your shop is 30 feet deep and your heater can only throw 20 feet, you get:

-

Hot ceiling air

-

Cold work area

-

Stratification

-

Weak temperature rise

-

Higher propane usage

-

Heater running longer than it should

Your gas bill goes up.

Your comfort goes down.

Your equipment takes the blame.

But the problem is design — not the heater.

📏 2. Tony’s Rule: A Heater Must Throw Heat At Least 75% of the Room’s Longest Dimension

Here’s the system design rule every installer must follow:

Throw distance must cover at least 75% of the room’s span.

If it doesn’t, your layout is wrong — period.

Examples:

24 × 30 garage

Longest span = 30 ft

Required throw = 0.75 × 30 = 22.5 ft

→ A 45K+ BTU heater works

24 × 40 shop

Longest span = 40 ft

Required throw = 30 ft

→ 60K–80K BTU heater required

30 × 50 barn

Longest span = 50 ft

Required throw = 37.5 ft

→ Use 80K–100K BTU, OR relocate heater to a long wall

If throw distance is too short, you either:

-

upgrade tonnage, or

-

relocate the heater for better penetration.

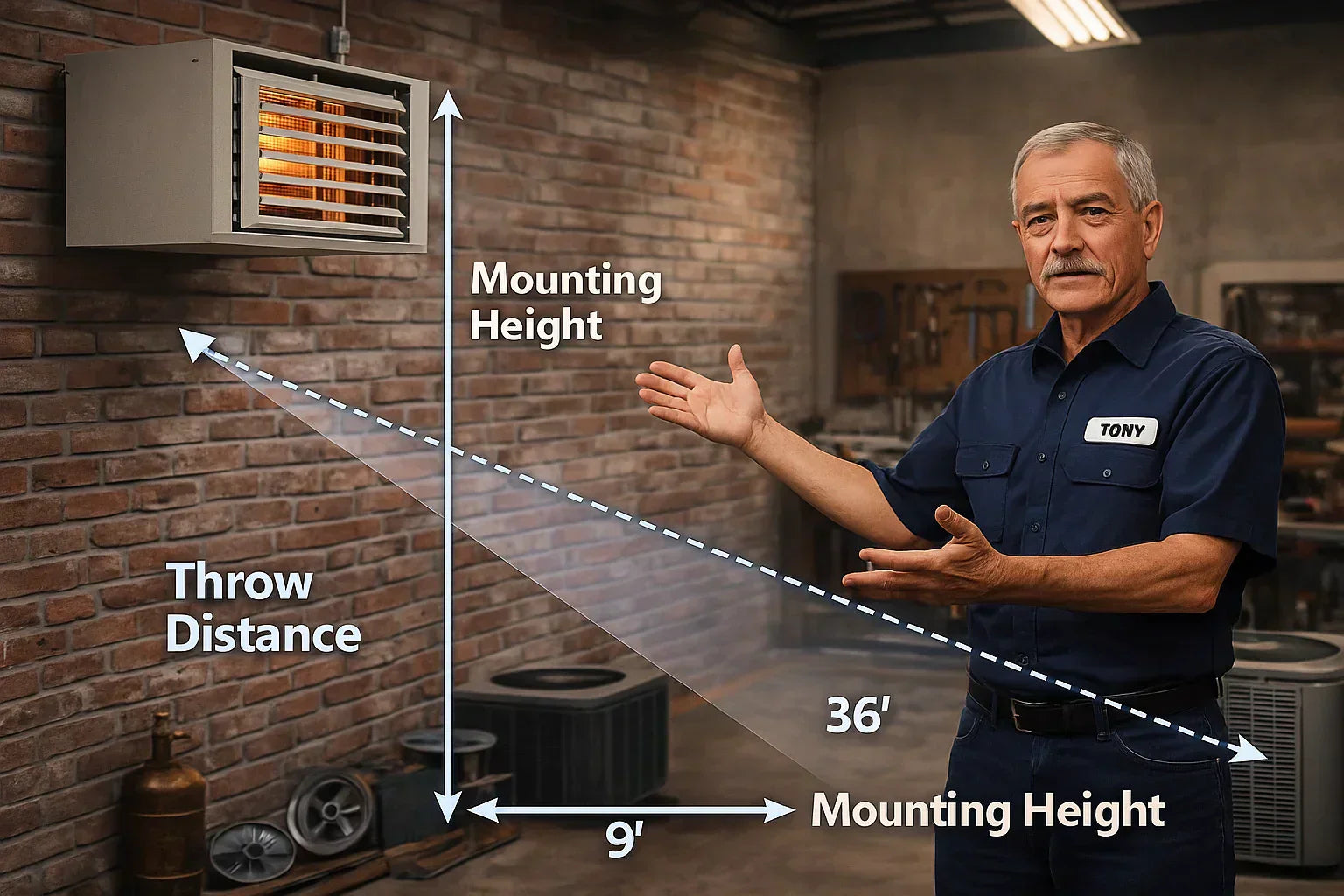

🏗️ 3. Wrong Mounting Height: The #1 Reason Heat Stays at the Ceiling

Let me tell you something I see almost daily:

People mount unit heaters WAY too high.

The higher the heater, the more:

-

warm air floats upward

-

throw distance decreases

-

stratification increases

-

the flame cycles harder

-

the shop floor stays cold

Ideal mounting heights (Tony’s field data):

-

8 ft ceiling → mount heater at 7 ft

-

9–10 ft ceiling → mount at 8 ft

-

12–14 ft ceiling → mount at 10–11 ft

-

16–20 ft pole barn → mount at 12–14 ft (with steeper downward angle)

Manufacturers may allow higher mounting, but they’re assuming perfect airflow, which no real shop has.

Mount it too high and your BTUs become useless.

🎯 4. Angle Matters: Why You MUST Aim Heat Downward (Not Straight)

You cannot blow heat horizontally across a room and expect it to reach the floor.

Heated air rises.

It always has.

It always will.

Tony’s Rule of Angle

Aim the heater 15°–20° downward toward the floor zone where warming matters.

What this angle does:

✔️ Pushes warm air into occupied space

✔️ Forces circulation instead of stratification

✔️ Increases effective throw distance

✔️ Keeps ceiling temps lower

✔️ Reduces heat loss at the roof deck

This is why Reznor UDX and Modine Hot Dawg units allow adjustable swivel mounts — because angle is everything.

🌡️ 5. The Stratification Nightmare: When Ceiling Air Is 100°F and the Floor is 55°F

Every shop has seen this phenomenon:

You turn on the heater and 20 minutes later…

-

The rafters feel like a sauna

-

The garage floor still feels like an ice rink

-

The thermostat (mounted mid-height) reads “warm”

-

The heater cycles off even though you’re freezing

This is stratification — and it is ALWAYS caused by:

❌ Too high mounting height

❌ Too little downward angle

❌ Poor throw distance

❌ No air mixing

A stratified shop wastes massive propane because the heater keeps reheating trapped ceiling air.

🌀 6. Circulation and Airflow: Your Heater Cannot Do It Alone

Unit heaters create directional airflow, not full-room mixing.

If the room layout blocks circulation, the heater loses efficiency.

Worst offenders:

-

Shelving directly opposite heater

-

Car lifts

-

Farm equipment parked under heater

-

Partition walls

-

Poorly placed workbenches

-

Tall storage racks

-

Closed overhead doors with no return path

Tony’s Fix

You must create a circular airflow loop, where heat can:

-

travel outward

-

hit an opposite wall

-

bounce downward

-

return to the heater side of the room

No airflow loop = cold pockets + high bills.

Pro tip:

Small ceiling fans on low reverse speed solve 90% of stratification problems.

🔧 7. The “Line of Fire” Concept — Where Heat Actually Lands

If a heater’s line of fire (the main airflow cone) doesn’t reach the working area, you might as well heat the ceiling.

The line of fire must hit:

-

garage floor traffic lanes

-

workshop bench areas

-

vehicle bays

-

walk paths

-

tool zones

You NEVER aim the heater at:

-

doors

-

windows

-

shelving

-

toolboards

-

uninsulated walls

Tony’s Rule

Aim heat where people stand, not where heat escapes.

🧪 8. How Mounting Mistakes Show Up as “Heater Problems”

Here’s the kicker:

90% of “equipment problems” are actually mounting mistakes.

Symptoms and their causes:

| Symptom | Real Cause |

|---|---|

| Slow heat-up | Throw too short / heater too high |

| Cold floor | No downward angle / no circulation |

| Hot ceiling | Overpowered vertical buoyancy |

| High propane bill | Stratification loss |

| Heater short cycles | Thermostat reads warm air mid-height |

| Weak airflow feel | Mounted too far from work zone |

| Long run times | Air never reaches far wall |

Installers blame:

-

gas pressure

-

burner quality

-

brand

-

thermostat

-

or “bad heater”

But the problem is always distance, height, or angle.

📘 9. Verified External Sources (Up to 6) Supporting Throw, Mounting & Airflow Science

-

Modine Hot Dawg Installation Manual (Mounting & Throw Charts)

https://modinehvac.com/ -

Reznor UDX Engineering Specifications

https://www.reznorhvac.com -

Building Science Corporation – Air Mixing & Comfort Control

https://buildingscience.com -

HVAC Ventilation & Throw Distance Principles (Titus HVAC)

https://www.titus-hvac.com/

These all confirm what Tony teaches:

Distance + direction + height = actual usable heat.

🔍 10. Real Install Examples from Tony’s Logbook

Case 1: The “Cold Garage” Mystery

24 × 30 attached garage

Heater: 45K BTU

Mounting height: 10 ft

Angle: horizontal

Throw: 18 ft → needed 23 ft

Fix: lower to 8 ft, 20° downward angle

Result: Floor temp rose 14°F in 20 minutes.

Case 2: Barn With 16-Foot Ceilings

Original mounting height: 15 ft

Throw: 30 ft

But all heat trapped at rafters.

Fix: lower to 11.5 ft, use steep 25° angle, add ceiling fan

Result: Full building warmed evenly.

Case 3: Mechanic Shop

60K BTU heater

Mounted correctly

But airflow blocked by a car lift.

Fix: shift heater 4 ft sideways

Result: Temperature rise doubled.

🧰 11. Tony’s Perfect-Mount Formula (Use This On Every Install)

✔️ Step 1 — Measure the longest span

(heater must cover at least 75% with throw)

✔️ Step 2 — Choose mounting wall

(prefer long-sweep throw parallel to longest dimension)

✔️ Step 3 — Mount at correct height

(never “max height allowed,” always optimal height)

✔️ Step 4 — Aim 15–20° downward

(always aim at floor/work zone)

✔️ Step 5 — Ensure airflow return path

(no blockages opposite heater)

✔️ Step 6 — Test with tissue or smoke

(confirm circulation pattern)

If the airflow loop isn’t correct, relocate or re-angle the heater.

🚀 Conclusion: Throw, Height, and Angle Determine EVERYTHING

Every propane or gas unit heater — whether it’s a Reznor, Modine, Hot Dawg, or anyone else — lives or dies by three things:

Throw distance

Mounting height

Downward angle

Get these wrong and your BTUs vanish into the ceiling.

Get them right and you get:

✔️ faster warm-up

✔️ lower propane bills

✔️ stable room temp

✔️ less stratification

✔️ safer operation

✔️ even coverage

Most installers never learn this.

But now you have Tony’s exact playbook.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Forget Square Footage — Why Ceiling Height Matters More Than BTUs in Unit Heater Sizing