By Tony — your no-nonsense system design guy who’s tired of seeing heaters starve for air

🛠️ Introduction: The Silent Killer of Propane Performance

Let me tell you something most installers won’t admit:

Propane heaters don’t fail because of the heater.

They fail because of bad combustion-air planning.

I’ve walked into hundreds of shops, garages, barns, and warehouses where the homeowner swore their propane heater “just doesn’t burn right.”

-

Weak flame

-

Delayed ignition

-

Flame rollout

-

Sooting

-

Short cycling

-

High-limit trips

-

And the classic “it used to work fine until we sealed the building”

Every one of these symptoms points to one problem — your heater is starving for air.

And here’s the part nobody calculates correctly:

**The combustion air equation isn’t optional.

It’s physics. And if you get it wrong, nothing else in your system design will matter.**

This article breaks down the exact rule I use on every Reznor UDX install — the rule that stops heaters from suffocating, burning dirty, and shutting down.

Reznor UDX 60,000 BTU Propane Unit Heater

⚙️ 1. Why Propane Heaters Need Perfect Airflow — Not “Good Enough” Airflow

Propane burns clean only if you give it enough oxygen. A propane flame that’s even slightly oxygen-starved becomes unstable.

Without correct combustion air, you’ll see:

-

Yellow tips on flame

-

Low flame height

-

Burner flutter

-

Heavy soot

-

Carbon monoxide risk

-

Rollout tripping your safety switches

-

A heater that slowly destroys itself from the inside

Manufacturers like Reznor and Modine mention these problems in their manuals, but they bury the real math deep in the fine print.

Most DIY installers never see it.

Most pros skip it.

But I don’t.

Because air is a fuel — and your heater needs just as much of it as propane.

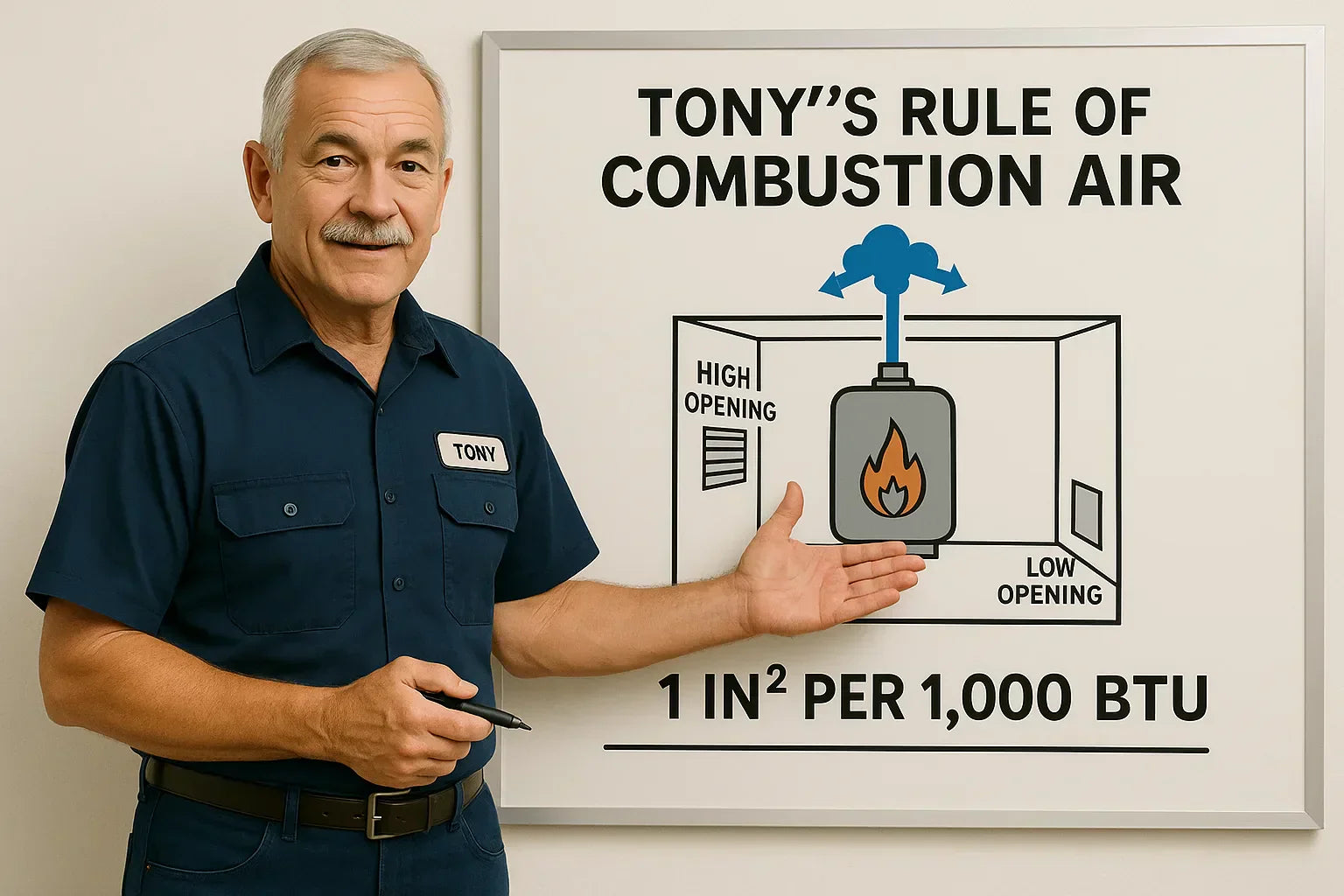

🧮 2. Tony’s Rule of Combustion Air: The One Equation You Cannot Ignore

Here it is — the thing 90% of installers get wrong:

👉 For every 1,000 BTUs, you need 1 square inch of free-air opening.

Let’s apply it.

Example: 60,000 BTU Propane Heater

60,000 BTUs ÷ 1,000 = 60 square inches of free air needed

That means ONE of the following:

-

a 10" × 6" opening

-

a 12" × 5" opening

-

a 20" × 3" slot

Or two half-size openings:

-

30 sq in high + 30 sq in low

-

One near ceiling, one near floor

But here’s the catch most people miss:

That’s “free area,” not louvered area.

A grill or vent cover may reduce airflow by 30–60%.

So a 10" × 6" louver might only give you 30–40 sq in of free area, not 60.

That’s why you MUST oversize combustion-air openings.

🏗️ 3. Where Most Installers Mess Up: Tight Garages, Sealed Barns & Insulated Shops

Older buildings leaked enough air naturally to feed a heater.

Modern spaces?

Not a chance.

-

Spray-foam garages

-

Weather-sealed workshops

-

Insulated metal buildings

-

Barns converted into hobby shops

-

Storage rooms with fire-rated doors

-

Mechanical rooms with poor ventilation

These are airtight boxes.

A 60,000 BTU heater in a tight space can pull the room into negative pressure within seconds.

The result?

Propane flame collapses.

Burner chokes.

Soot starts forming.

Safety shutdowns begin.

People blame the heater.

But the heater isn’t wrong.

The room is.

🌬️ 4. The Difference Between Combustion Air and Ventilation Air

Let’s break something installers confuse constantly.

Combustion Air

Used by the burner.

Leaves the room through the exhaust.

Must be replaced.

Ventilation Air

Used for indoor air quality.

Controls humidity, odors, VOCs.

Not directly tied to heater performance.

You need both, but combustion air is the one that impacts burner stability.

Some installers assume a bathroom vent or a window crack is “good enough.”

Nope.

Combustion air must be:

-

Dedicated

-

Permanent

-

Unobstructed

-

Sized correctly

-

Protected from freezing shut

Ventilation air cannot substitute for it.

🏷️ 5. Verified External Resources on Air Requirements (6 Max)

Here are reputable combustion-air sources to back Tony’s rule:

-

International Fuel Gas Code (IFGC) — Combustion Air Requirements

https://codes.iccsafe.org/content/IFGC2021P1/chapter-3-general-regulations -

ASHRAE Ventilation Standards Overview

https://www.ashrae.org/technical-resources/bookstore -

Reznor UDX Equipment Manual (Combustion Air)

https://www.reznorhvac.com -

Propane Education & Research Council (PERC) Technical Library

https://www.propane.com/ -

NIOSH Combustion Air & CO Safety Standards

https://www.cdc.gov

These references align with Tony’s one-inch-per-1,000-BTU rule used across the industry.

🪟 6. The Two-Opening Rule — High and Low Combustion Air

If your heater pulls air from the indoors (not direct-vent), you need TWO openings:

✔️ High opening

Near the ceiling

Releases hot air

Prevents stagnation

✔️ Low opening

Near the floor

Feeds combustion

Replaces air exhausted via flue

This prevents the room from entering negative pressure, which collapses the flame.

Most installations fail because the installer cuts only one opening — usually high.

That instantly starves the burner.

🔩 7. Why Direct-Vent Solves 80% of Combustion-Air Problems

The Reznor UDX comes with a sealed-combustion option, which I highly recommend for any:

-

garage

-

shop

-

barn

-

spray-foam structure

-

workspace with chemical fumes

-

dusty environment

-

building with vehicles or engines

Direct-vent (two-pipe) systems feed all combustion air from outside, not the room.

Benefits:

✔️ No oxygen stealing from the room

✔️ Cleaner flame

✔️ Zero negative pressure effects

✔️ No CO risk from backdrafting

✔️ Perfect for tight buildings

✔️ Consistent BTU output

✔️ Works even in dusty environments (woodworking shops especially)

Direct-vent is the “Tony-approved” method for best performance.

💨 8. The Snowflake Problem — When Outdoor Air Gets Blocked

Even perfect systems fail when winter arrives.

Common snow-related combustion air issues:

-

Snow drift covering intake grill

-

Ice buildup on vent hood

-

Frozen louvers

-

Wind-driven snow clogging openings

-

Rodents nesting inside unprotected vents

A blocked intake can drop your combustion air to zero instantly — and your heater will flame out, cycle, or trip safeties.

Tony’s fix:

Use a vent termination hood with a built-in screen and protect it with a small weather shelter.

🔥 9. Real Example: The 60,000 BTU Heater That Burned Yellow Every Morning

A shop owner called me because his Reznor UDX burner was:

-

yellow

-

lazy

-

unstable

-

sometimes popping on ignition

I checked fuel pressure.

Perfect.

Checked manifold pressure.

Perfect.

Checked vent.

Perfect.

Then I looked around the shop.

Spray-foam walls.

New rubber seals around the garage door.

Insulated ceiling.

Tight as a submarine.

The heater was suffocating.

Solution:

I cut a 10" × 12" low vent and a 10" × 6" high vent into the exterior wall.

Flame turned perfect blue.

Ignition became crisp.

Burner sounded healthy.

System design, not equipment failure.

📘 10. Tony’s Combustion Air Checklist (Print This)

Before firing a propane heater, confirm all below:

✔️ You have 1 sq in per 1,000 BTUs

✔️ You have a high opening

✔️ You have a low opening

✔️ Openings are permanently unobstructed

✔️ Louvers don’t reduce the opening below required area

✔️ The room has no negative-pressure sources

(exhaust fans, dryers, paint booths, bathroom fans)

✔️ No chemicals stored near heater intake

(paints, solvents, carb cleaner, etc.)

✔️ Direct-vent used for tight rooms

✔️ Intake hood is protected from snow, ice, pests

✔️ Room has a fresh air path for replacement air

This checklist alone fixes more heater problems than any brand-new component.

🚀 Conclusion: The Heater Isn’t the Problem — The Air Is

If there is ONE thing every propane heater installer gets wrong, it’s combustion air.

They use the wrong equation.

They guess instead of calculating.

They trust natural infiltration.

They forget the room changes over time.

They assume direct-vent is overkill.

They think louvers offer full airflow when they don’t.

But Tony’s rule never lies:

1 square inch of free-air opening for every 1,000 BTUs — or your propane heater WILL burn poorly.

And when you design around that one rule?

Your heater burns hotter, cleaner, quieter, safer — and lasts years longer.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Line of Fire: How Poor Throw Distance and Wrong Mounting Height Destroy Heat Coverage