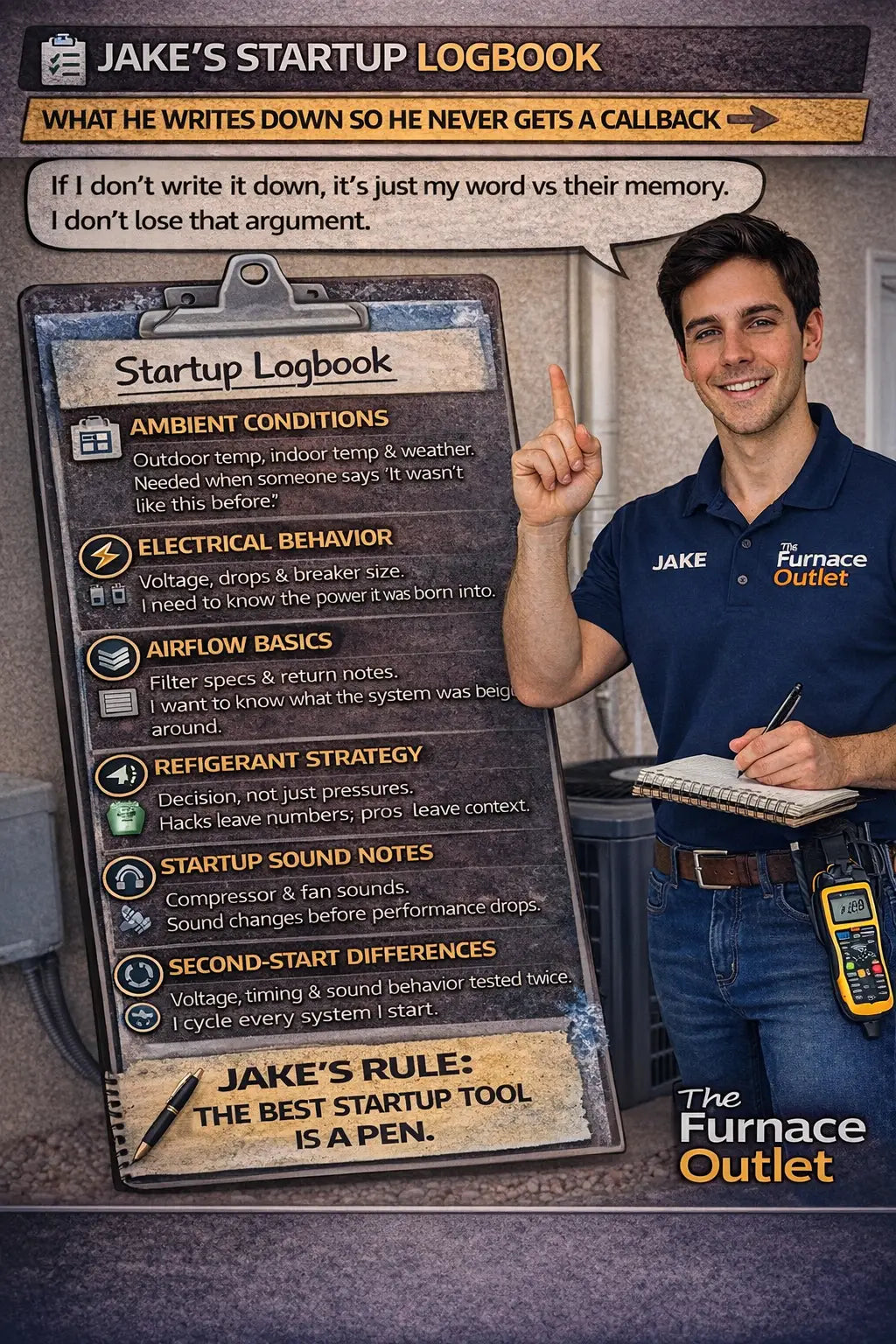

📋 Jake’s Startup Logbook

What He Writes Down So He Never Gets a Callback

Callbacks don’t usually come from bad equipment.

They come from missing context.

I can’t tell you how many times I’ve been called back to a “problem system” that wasn’t actually broken — it just didn’t have a baseline.

That’s why I keep a startup logbook.

Not paperwork for paperwork’s sake.

Not notes for the office.

Proof — for me, the homeowner, and the system itself.

This article breaks down exactly what I record during startup, why it matters, and how those notes save me hours, arguments, and unnecessary warranty claims — especially on R-32 systems like the Goodman GLXS3B3010.

🧠 Why Startup Notes Matter More Than Perfect Numbers

Numbers change.

Conditions change.

Homes change.

What doesn’t change is the value of knowing how the system behaved on Day One.

When something sounds different, runs longer, or feels off six months later, my logbook tells me:

-

Was it always like this?

-

Or did something change?

Without that baseline, troubleshooting turns into guessing — and guessing creates callbacks.

📅 What Jake Records Before Startup Even Begins

My logbook starts before power.

I record:

-

Install date

-

Equipment model numbers

-

Line set length and routing

-

Indoor and outdoor unit pairing

-

Filter type and size

Why?

Because mismatches and assumptions are the root of half the problems I see later.

If it’s not written down, it doesn’t exist.

🌡️ Ambient Conditions Are Not Optional

Every startup entry includes:

-

Outdoor temperature

-

Indoor temperature

-

Weather conditions

Why this matters:

Startup readings taken at 62°F mean something very different than readings at 92°F.

Six months later, when someone says, “It never ran like this before,” I can check the conditions and respond with facts — not opinions.

⚡ Electrical Baselines I Always Record

I don’t just check voltage.

I document it.

My logbook includes:

-

Line voltage at rest

-

Voltage under compressor load

-

Any observed voltage drop

-

Breaker size

This protects me when:

-

A power issue develops later

-

A homeowner upgrades electrical loads

-

A compressor fails prematurely

Electricity leaves fingerprints. You just have to write them down.

For electrical standards reference, I align with the NEC:

🔗 https://www.nfpa.org

🌬️ Airflow Notes That Save Arguments Later

Airflow problems rarely show up on Day One — they show up after filters clog or furniture moves.

That’s why I document:

-

Filter type (MERV rating)

-

Return configuration

-

Any airflow limitations I observe

When airflow changes later, I can prove:

-

What the system was designed around

-

What has changed since

This single habit has saved me more callbacks than any tool I own.

🧊 Refrigerant Strategy (Not Just Numbers)

I don’t just write down pressures.

I write down:

-

Whether refrigerant was adjusted

-

How long the system stabilized

-

Why adjustments were or weren’t made

That context matters more than the numbers themselves.

Especially on R-32 systems, where early readings can mislead, documenting decision-making protects you when someone questions results later.

EPA refrigerant handling guidance:

🔗 https://www.epa.gov/section608

🔊 Startup Sound Notes (Yes, Really)

This surprises people — but I log sound observations.

I note:

-

Compressor tone

-

Fan startup behavior

-

Any abnormal noises (or lack thereof)

Why?

Because sound changes first.

When a homeowner says, “It sounds louder than it used to,” I can answer honestly:

-

Was it always like that?

-

Or is something new happening?

🔁 First Start vs Second Start Differences

If I cycle the system twice (and I always do), I record:

-

Differences between first and second startup

-

Any timing changes

-

Any voltage or sound changes

This gives me insight into:

-

Thermal expansion issues

-

Electrical instability

-

Marginal conditions that worsen over time

Most techs skip this.

Most callbacks don’t.

🏗️ Why This Is Critical on the Goodman GLXS3B3010

The Goodman 2.5-Ton 13.4 SEER2 R-32 condenser is a stable, predictable system — if it’s documented correctly.

When something changes later, the logbook tells me whether:

-

The system changed

-

Or the environment changed

That difference matters.

📘 Industry Best Practices Jake Aligns With

Documentation isn’t just my habit — it’s industry-backed.

I align with:

-

ACCA system verification principles:

🔗 https://www.acca.org/standards

Good notes protect techs and homeowners alike.

📋 Jake’s Startup Logbook Checklist

Before I close my logbook, I confirm I’ve recorded:

-

Ambient conditions

-

Electrical behavior under load

-

Airflow configuration

-

Refrigerant strategy

-

Startup sounds

-

First vs second start differences

If it’s not written down, it didn’t happen.

🧠 Jake’s Rule of Thumb

Callbacks don’t come from systems you understand.

They come from systems you forgot.

🔑 Jake’s Final Word

My logbook isn’t about covering myself.

It’s about knowing the system better than anyone else ever will.

When a call comes in weeks, months, or years later, I’m not guessing — I’m referencing facts.

Remember this:

The best startup tool isn’t a meter — it’s a pen.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Why Most Startup Failures Don’t Show Up Until Day 30 — Jake Explains