Jake Explains the Delay That Tricks Homeowners, Techs, and Even Good Equipment

If startup mistakes caused instant failures, this job would be easy.

You’d flip the breaker.

The system would fail.

You’d fix it.

But that’s not how HVAC actually works.

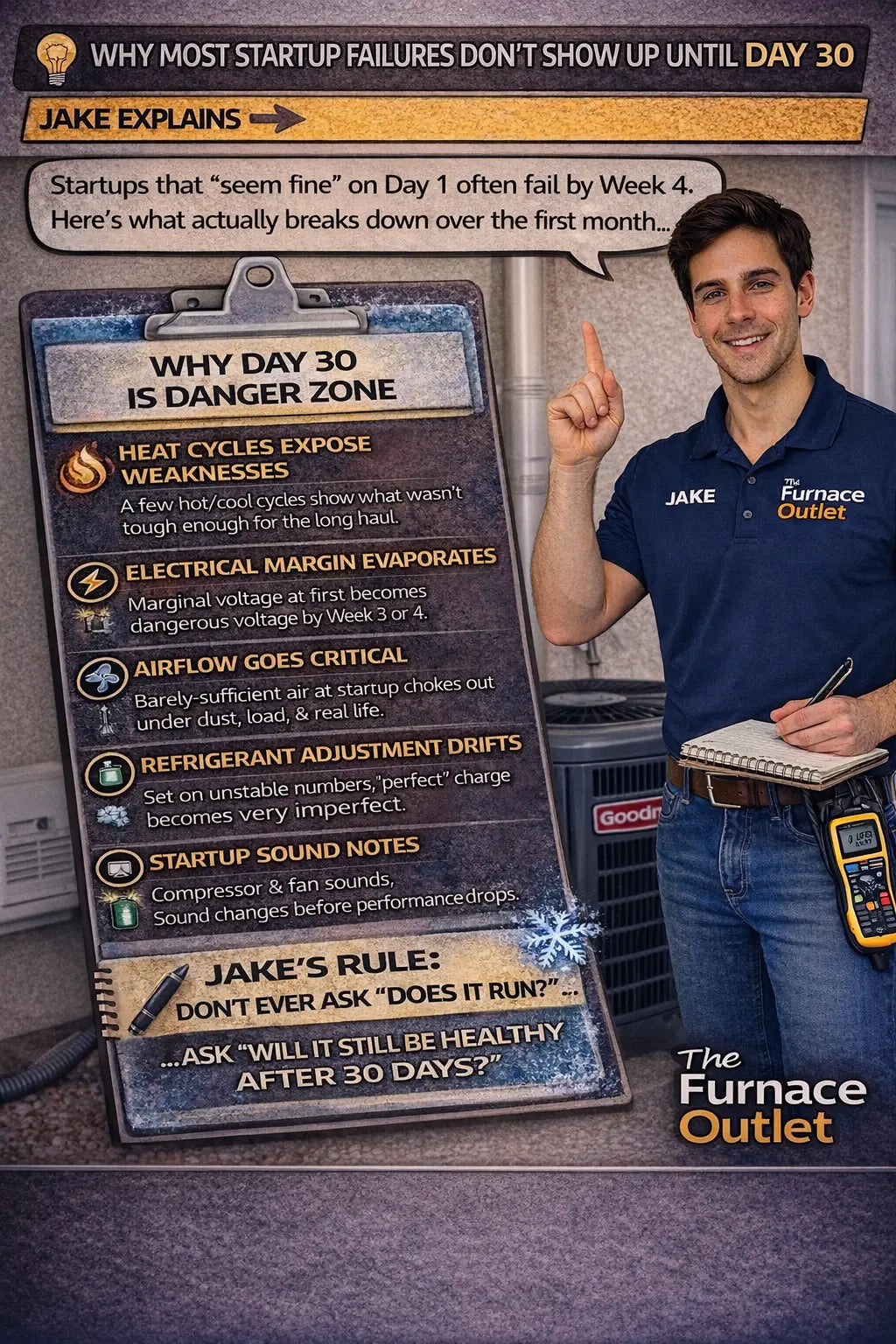

The most expensive, frustrating, reputation-killing problems I see don’t show up on Day One. They show up three weeks later—after the installer has been paid, the homeowner has relaxed, and the system has quietly been stressed just enough times to start breaking down.

This article explains why Day 30 is the danger zone, especially for modern systems like R-32 condensers such as the Goodman GLXS3B3010, and what actually happens inside the system during those first few weeks.

🧠 The Biggest Startup Myth: “If It Runs Today, It’s Fine”

This is the lie that ruins good installs.

Most startup mistakes don’t prevent operation.

They reduce margin.

The system still runs:

-

Just a little hotter

-

Just a little louder

-

Just a little less efficient

And those “just a littles” compound with every heat cycle.

By Day 30, the system has:

-

Fully heat-soaked multiple times

-

Experienced load variation

-

Settled into its true operating pattern

That’s when the damage starts showing.

🔥 Heat Cycles Are the Real Stress Test

Startup happens once.

Heat cycles happen hundreds of times.

Every on/off cycle causes:

-

Copper expansion and contraction

-

Electrical resistance changes

-

Oil movement and redistribution

Startup mistakes don’t break parts immediately.

They make parts work harder every single cycle.

Eventually, something gives.

⚡ Why Electrical Problems Hide at First

Marginal voltage is the classic delayed failure.

On Day One:

-

Wires are cool

-

Resistance is low

-

Voltage drop is minimal

By Day 30:

-

Conductors heat-soak

-

Loose lugs loosen further

-

Resistance increases

The compressor doesn’t fail instantly.

It just runs hotter and longer — until it doesn’t.

This is why I test voltage under load, not just at rest.

NEC electrical behavior guidance:

🔗 https://www.nfpa.org

🌬️ Airflow Problems Get Worse Over Time

Airflow restrictions almost never announce themselves immediately.

What changes over the first 30 days:

-

Filters load with dust

-

Furniture gets rearranged

-

Registers get adjusted

-

Doors start staying closed

If airflow was marginal at startup, it becomes critical after a few weeks.

The system doesn’t suddenly fail.

It slowly overheats, over-pressurizes, and loses efficiency.

That’s why airflow must be verified — not assumed.

ACCA airflow fundamentals:

🔗 https://www.acca.org/standards

🧊 Refrigerant Mistakes Age Systems Quietly

Early refrigerant adjustments made during unstable startup conditions are the most common cause of Day 30 failures.

Here’s the pattern:

-

Refrigerant is adjusted too early

-

System stabilizes later

-

Pressures drift

-

Compressor runs hotter than intended

Nothing trips.

Nothing alarms.

But by Week 3 or 4, oil breakdown, heat stress, and efficiency loss are already happening.

EPA refrigerant handling guidance:

🔗 https://www.epa.gov/section608

🔊 Noise Is Usually the First Symptom (and the First Complaint)

Homeowners rarely call and say, “My compressor amperage seems high.”

They say:

-

“It’s louder than before”

-

“It sounds different at night”

-

“It didn’t used to do that”

Those sounds started on Day One — but only became noticeable after weeks of stress.

That’s why listening during startup matters more than most people think.

🔁 Why the Second Start Predicts the First Callback

Most delayed failures are visible on the second startup — if someone bothers to watch.

The second start shows:

-

Thermal expansion issues

-

Electrical instability under warm conditions

-

Marginal airflow compensation

Skipping the second start is like skipping the test drive after engine repairs.

📋 Why Documentation Becomes Your Best Defense

By Day 30, memory fades.

Homeowners remember how it feels now, not how it ran before.

That’s why startup documentation matters:

-

Ambient conditions

-

Electrical behavior

-

Airflow configuration

-

Sound observations

When something changes, you can prove whether the system changed — or the environment did.

🏗️ Why This Is Common on the Goodman GLXS3B3010 (and Not the Unit’s Fault)

The Goodman 2.5-Ton 13.4 SEER2 R-32 condenser is efficient, responsive, and honest.

That’s the problem.

Efficient systems expose mistakes faster than older, less sensitive equipment. They don’t hide marginal installs — they magnify them.

When a Day 30 failure happens, it’s almost never because the unit was bad.

It’s because the startup foundation was weak.

🧠 Jake’s Day-30 Prevention Rule

If you want to prevent delayed failures:

-

Don’t rush startup

-

Don’t trust early numbers

-

Don’t skip airflow

-

Don’t ignore sound

-

Don’t skip documentation

Most Day 30 failures were visible on Day One — just ignored.

🔑 Jake’s Final Word

Startup failures don’t hide.

They wait.

They wait for heat cycles.

They wait for load.

They wait for shortcuts to add up.

If you want fewer callbacks, stop asking:

“Does it run?”

And start asking:

“Will it still be healthy after 30 days?”

Because that’s the only startup question that really matters.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: If Jake Had to Startup This Goodman System Blindfolded, This Is the Order He’d Use