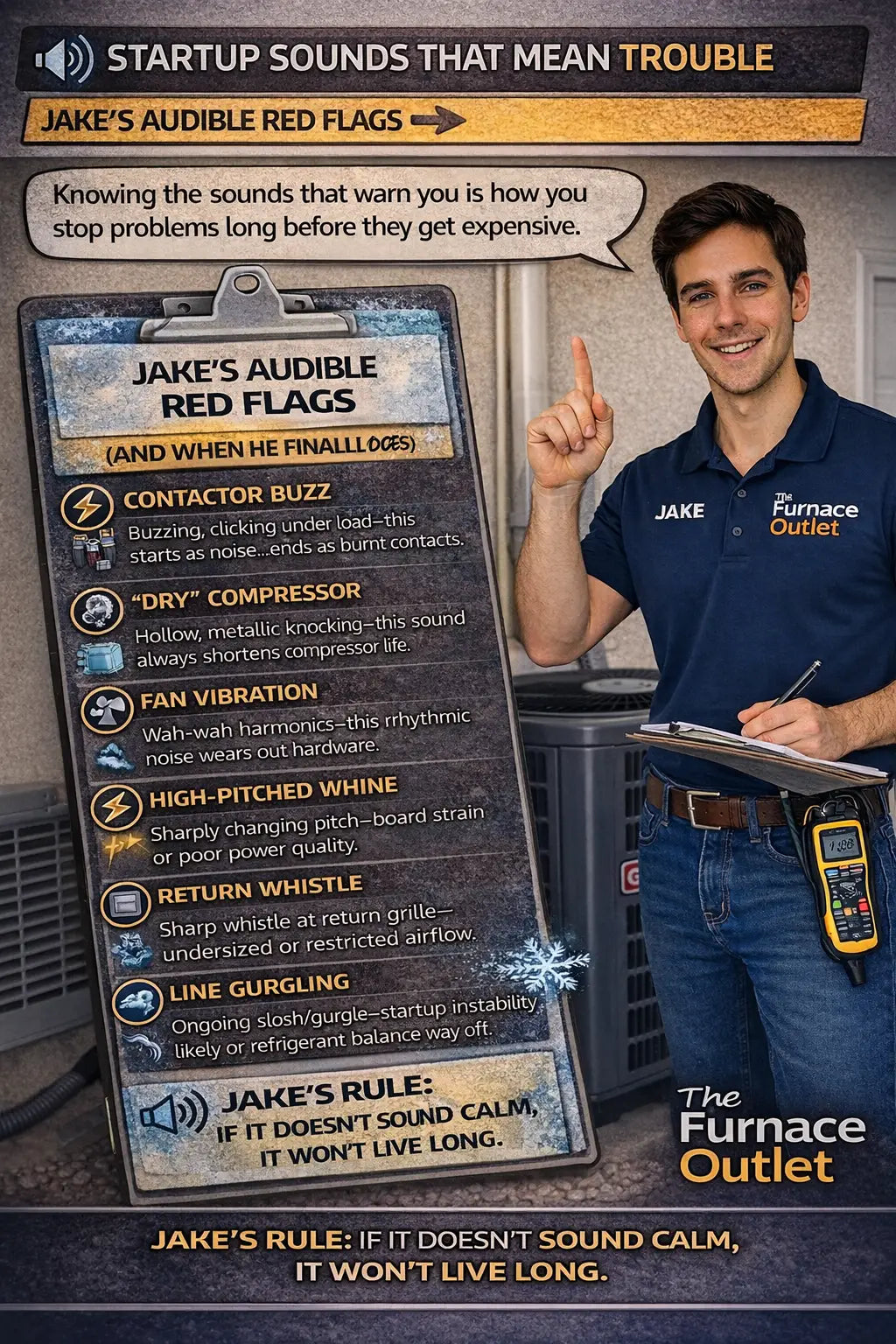

Jake’s Audible Red Flags That Catch Failures Before Gauges Ever Do

Before gauges stabilize…

Before error codes appear…

Before homeowners complain…

The system tells you what’s wrong — out loud.

Most techs are trained to look for problems.

I was trained to listen.

Because every bad startup I’ve ever fixed was noisy long before it failed. The installer just didn’t know which sounds mattered — or worse, assumed they were “normal.”

This article breaks down the specific startup sounds I never ignore, especially on modern R-32 systems like the Goodman GLXS3B3010, where small noises usually mean big problems later.

🧠 Why Sound Is the First Honest Diagnostic Tool

Pressure readings lie early.

Voltage can look acceptable.

Airflow can seem fine.

But sound doesn’t fake it.

Mechanical stress, electrical instability, airflow restriction, and refrigerant imbalance all show up acoustically — often in the first minute of startup.

That’s why I stand still during startup.

No gauges. No phone. No talking.

Just listening.

🔌 ⚠️ Contactor Buzz or Chatter (Electrical Instability)

A healthy contactor engages cleanly and quietly.

Red flags:

-

Buzzing after engagement

-

Rapid clicking

-

Chattering under load

What it usually means:

-

Weak control voltage

-

Poor grounding

-

Loose electrical connections

This sound doesn’t go away on its own. It leads to:

-

Burnt contacts

-

Voltage drop

-

Premature board failure

If I hear this, startup stops immediately.

🔊 🧊 Hollow or “Dry” Compressor Sound

This is one of the most important sounds to learn.

A healthy compressor sounds:

-

Smooth

-

Even

-

Confident

Trouble sounds like:

-

Hollow knocking

-

Metallic ticking

-

A dry, echo-like tone

Common causes:

-

Oil migration issues

-

Refrigerant imbalance

-

Liquid flash at startup

This doesn’t always cause instant failure — but it always shortens compressor life.

🌬️ 🎶 Fan Harmonics or Oscillation

Condenser fans should start smoothly and settle quickly.

Red flags:

-

Wobble

-

Rhythmic pulsing

-

A “wah-wah” harmonic sound

What it usually means:

-

Blade imbalance

-

Improper mounting

-

Cabinet resonance

Left alone, this vibration transfers into:

-

Coil fatigue

-

Line set wear

-

Mounting hardware loosening

Noise complaints almost always start here.

🧯 ⚡ High-Pitched Electrical Whine

This one gets dismissed too often.

If I hear:

-

A sharp electrical whine

-

Pitch changing with load

-

Noise coming from the electrical compartment

I suspect:

-

Transformer stress

-

Inverter or board strain

-

Poor incoming power quality

This sound usually shows up before electrical failures — not after.

🌬️ 📣 Return Whistle or Supply Hiss (Airflow Trouble)

Airflow problems are loud — if you know where to listen.

Red flags:

-

Whistling at the return grille

-

Sharp hissing at supply registers

-

Blower ramping aggressively

These sounds usually indicate:

-

Undersized returns

-

Over-restrictive filters

-

Excessive static pressure

And here’s the key:

You cannot tune refrigerant around airflow noise.

Fix airflow first — or every other adjustment will lie.

🔄 🧊 Sloshing or Gurgling at Startup

This sound scares homeowners — and it should concern techs too.

Sloshing or gurgling often means:

-

Refrigerant velocity instability

-

Improper line set pitch

-

Early oil return issues

During the first moments of startup, some movement is normal — but persistent gurgling is not.

If it doesn’t fade as the system stabilizes, I investigate immediately.

🛑 🚫 Sounds Jake Never “Waits to See”

These sounds don’t get a grace period:

-

Metallic grinding

-

Loud clacks on startup

-

Sharp snaps during shutdown

If I hear any of those:

Startup stops. Period.

Because sounds don’t heal themselves.

🧠 Why R-32 Systems Make Sound Diagnostics More Important

R-32 systems are efficient — and honest.

They:

-

React faster to imbalance

-

Amplify airflow and voltage issues

-

Expose poor startups early

Older systems might tolerate noise for years.

R-32 systems convert noise into wear immediately.

That’s why listening matters more now than ever.

🧰 Tools I Trust — and Why My Ears Still Matter Most

I use tools to confirm problems — not discover them.

But no meter replaces experience.

Sound is instant.

Sound is honest.

Sound never lies.

🏗️ Why This Matters on the Goodman GLXS3B3010

The Goodman 2.5-Ton 13.4 SEER2 R-32 condenser is a quiet, stable unit when everything is right.

When something is wrong, it tells you — early and clearly.

Ignoring those warnings is how good equipment gets blamed for bad installs.

📘 Industry Guidance Jake Aligns With

While sound is experiential, electrical and airflow issues tied to noise are backed by standards:

-

ACCA airflow & system diagnostics:

🔗 https://www.acca.org/standards -

NEC electrical stability principles:

🔗 https://www.nfpa.org

📋 Jake’s Audible Startup Checklist

Before I trust a system, I confirm:

-

Contactor engages quietly

-

Compressor sounds smooth

-

Fan starts clean

-

No airflow whistle

-

No electrical whine

If it sounds stressed, it is stressed.

🧠 Jake’s Rule of Thumb

If you had to explain the noise away…

…it wasn’t normal.

🔑 Jake’s Final Word

Most startup failures don’t begin with alarms.

They begin with whispers.

And the tech who listens catches them early — while they’re still easy to fix.

Remember this:

If it doesn’t sound calm, it won’t live long.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Jake’s Startup Logbook: What He Writes Down So He Never Gets a Callback